Industrial Lifting Door

As an established player in industrial-door technology, SEPPES specializes in delivering lifts doors engineered for safety, energy efficiency, and sustained reliability in demanding environments. Our singular mission is to empower clients with door systems that consistently support operational excellence.

The Industrial Lifting Door line is at the heart of our offering. Constructed with precision robotics and premium-grade components, each door is subjected to rigorous testing to guarantee long service life and faultless operation. Ideal for logistics, heavy production, distribution, and commercial facilities, the doors adapt seamlessly to diverse application scenarios, enhancing workflow and protecting assets.

SEPPES: Your Premier Manufacturer Of Industrial Lifting Door

SEPPES stands at the forefront of the Chinese market, crafting world-class industrial sectional doors that set the benchmark for performance and security. Our mission is simple yet bold: deliver products that not only elevate operational efficiency but also safeguard environments across diverse sectors. Infusing each design with the latest technological advancements, we ensure that every door we produce is a seamless blend of dependability and forward-thinking innovation.

Core technology of Industrial Lifting Door

1. Durability And Safety

2.Efficient Capability

3. Flexibility

4. Customization

5. Easy to maintain

Industrial Lifting Door Data Sheet

| Specification | Details |

|---|---|

| Door Type | Industrial Lifting Door |

| Material | High-quality steel, aluminum, or insulated panels |

| Insulation | Polyurethane foam (optional) |

| Panel Thickness | 40mm – 60mm |

| Panel Width | Customizable |

| Finish | Standard RAL colors or custom finishes are available |

| Operation | Manual or motorized |

| Safety Features | Finger protection, cable break protection, and spring break protection |

| Wind Resistance | Up to Class 5 (EN 12424) |

| Thermal Insulation | U-value up to 0.5 W/m²K |

| Noise Reduction | Up to 25 dB |

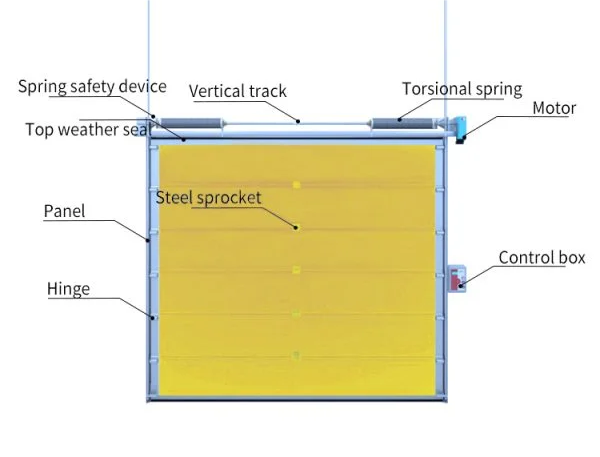

Sectional Lifting Door Detail Display

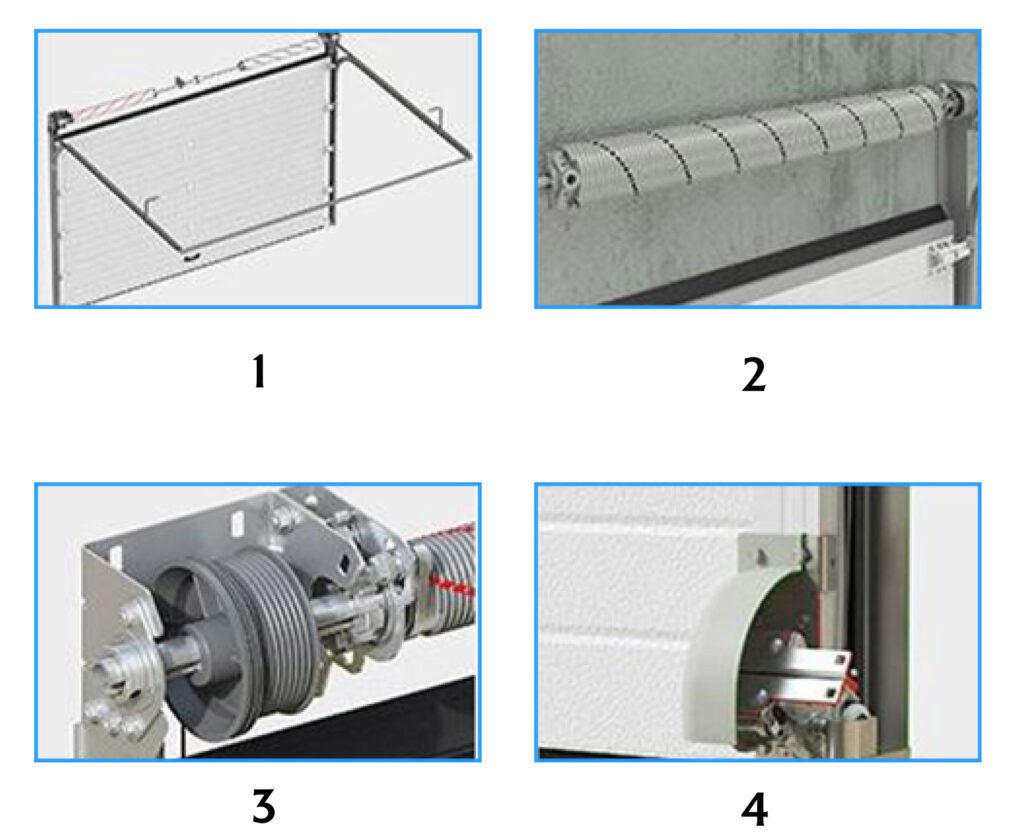

1. The door panel uses a pair of 1.5mm thick steel sheets bonded with a 48kg/m³ fire-resistant polyurethane core, bringing the total build-up to either 40mm (pinch-safe) or 50mm (pinch-free) thick. Edge zones are stiffened around the hinges with 4mm steel doubler plates._

2. The torsion spring is rated to compensate over 30,000 open-close cycles without fatigue. The spring anchor housing, winding arbor and take-up drum are all engineered from heat-treated high-strength A356.0 aluminum, cast to tight tolerances to reduce notch sensitivity._

3. A drop-lock retainer clamps the torsion shaft tube with stainless-steel cam pins instantly upon spring fracture, securing the door in a vertical position and safeguarding personnel._

4. A secondary inertia brake, concatenated with the lower guide track, automatically deploys a reticulated S705 steel wire loop catching a sliding block before the door can fall free, thus averting crush hazards upon cable rupture.

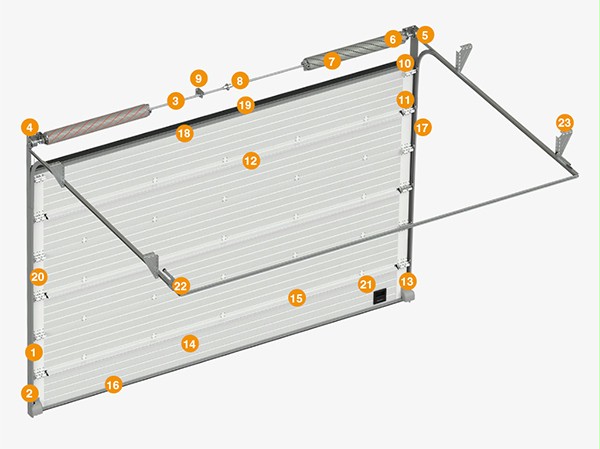

Sectional Door Details

5. Sheave 6. Torsion spring sleeve 7.Balance spring mechanism (torsion spring) 8.Coupling

9. Inner bracket 10.Top roller bracket 11.Roller bracket 12.Big back muscles (optional)

13. Wire rope break protection device 14.Sandwich door panel 15.Inner hinge

16. Bottom aluminum profile and bottom sealing strip 17.Side seal 18.Top aluminum profile

19. Top sealing strip 20.Panel side cover with fixing holes

21. Step handle 22.End buffer 23.Ceiling mounting bracket

Get A Quick Quotation Today

Applications of Industrial Lifting Door

Industrial lifting doors combine efficient access with sturdy reliability, making them indispensable across sectors like warehousing, manufacturing, and food processing. Constructed with tough materials, engineered for rapid, controlled cycles, and pairing seamlessly with user-friendly automation, they fit the rigorous expectations of modern infrastructure. Their performance is especially pronounced in the environments summarized here.

Resources on Industrial Lifting Door

Leading Industrial Lifting Door Manufacturers in China - SEPPES

Our company SEPPES is a professional Industrial Doors manufacturer. Products exported to 70 countries. Our products have multiple technical patents and EU CE certification with rich experience in fast shutter doors, rapid doors, high-speed roll-up doors, high-speed spiral doors, high-speed stacking doors, and PVC roller doors.

Why Choose Us

Industial Lifting Door enhance security, improve insulation, streamline workflows, and deliver safe, reliable access.

Cost-Effectiveness

Reason: Lower production costs due to economies of scale and affordable labor. Data Parameter: Average cost savings of 20-40% compared to Western manufacturers.

High Production Capacity

Reason: China's factories can handle large orders efficiently. Data Parameter: Lead times reduced by 30-50% for bulk orders.

Customization and Innovation

Reason: Manufacturers offer tailored solutions and advanced designs. Data Parameter: 70% of buyers report satisfaction with customization options.

Global Logistics Network

Reason: Well-established export infrastructure ensures smooth delivery. Data Parameter: 90% of shipments meet delivery deadlines.

Other Types of Sectional Doors You May Like

Our Amazing Clients

We have established cooperation with 70 countries and regions. Our powerful service internet and installation team helps us build relationships with customers who come from Europe, the Middle East, South America, and South East Asia.

We have authentic and authoritative certificates

SEPPES International Trademark Certification

Since our founding, SEPPES has secured trademark registrations across several countries. Each new certification symbolizes growing worldwide recognition of our brand, which, in turn, reinforces our competitive position and expands our influence in international markets.

Welcome to SEPPES's Indsutrial Doors Factories

Frequently Ask Questions

Q:What are industrial lifting doors?

A: Industrial lifting doors combine robust construction with vertical shifting to maximize floor space and streamline workflow in heavy-use environments.

Q:What materials are industrial lifting doors made of?

A: Common materials include galvanized steel for toughness, aluminum for lightweight transport, and double-skinned insulated panels to control interior climates without hefty energy costs.

Q: What industries commonly use industrial lifting doors?

A: You’ll find them in places such as distribution warehouses, automotive assembly plants, refrigerated loading docks, multilevel parking structures, waterfront cargo terminals, and entrances where restricted access is critical.

Q:What are the benefits of industrial lifting doors?

A: Among their standout advantages are a footprint-efficient overhead movement, proven longevity, strong thermal barriers, near-instant deployment, and integration with access security systems.

Q: Are industrial lifting doors customizable?

A: Indeed, doors of this type can be tailored to fit specified aperture dimensions, chosen construction substance, desired thermal ratings, and that may incorporate clear-view vision panels or integration with motorized opening sequences.

Q: What sizes are available for industrial lifting doors?

A:They come in different dimensions and can be tailored to heddle in everything from cozy doorways to soaring warehouses.

Q What is the typical lifespan of an industrial lifting door?

A:Regular upkeep can stretch the lifespan to two decades and sometimes beyond.

Q: What should I do if my industrial lifting door gets stuck?

A:Remove nearby items, confirm the power is live, then call in an expert if the problem won’t clear up.

Q: Can industrial lifting doors withstand harsh weather conditions?

A:These units are built to shrug off the elements; they perform in scorching heat, bitter cold, and gale-force rain alike.

Q:How much do industrial lifting doors cost?

A:Costs shift with width, thickness, and extras, generally landing in the 1200−1200−10,000 bracket, but some custom orders can soar higher.