Loading Dock Door

Greetings from SEPPES! Our newest advancement of Loading Dock Doors is now available. These Loading Dock Doors are SEPPES’ flagship products, engineered for enhancing safety, effectiveness, and particular convenience for both industrial and commercial loading bay areas.

To get more information on our Loading Dock Doors, please reach out to SEPPES. Our professionals are at your disposal for tailored recommendations aimed at bolstering your logistics operating efficiency.”

SEPPES: Your Premier Manufacturer Of Loading Dock Door

SEPPES is a leading manufacturer of high-quality Loading Dock Door, committed to providing exceptional products that enhance efficiency and security in various industries. Drawing inspiration from cutting-edge technology, we consistently deliver reliable and innovative door solutions.

Core Technology Of Loading Dock Door

1. Stability

2. Security

3. Protection

4. Visibility

5. Reliability

Loading Dock Door Data Sheet

| Specification | Details |

|---|---|

| Door Type | Industrial Sectional Door |

| Material | High-quality steel, aluminum, or insulated panels |

| Insulation | Polyurethane foam (optional) |

| Panel Thickness | 40mm – 60mm |

| Panel Width | Customizable |

| Finish | Standard RAL colors or custom finishes are available |

| Operation | Manual or motorized |

| Safety Features | Finger protection, cable break protection, and spring break protection |

| Wind Resistance | Up to Class 5 (EN 12424) |

| Thermal Insulation | U-value up to 0.5 W/m²K |

| Noise Reduction | Up to 25 dB |

Loading Dock Door Detail Display

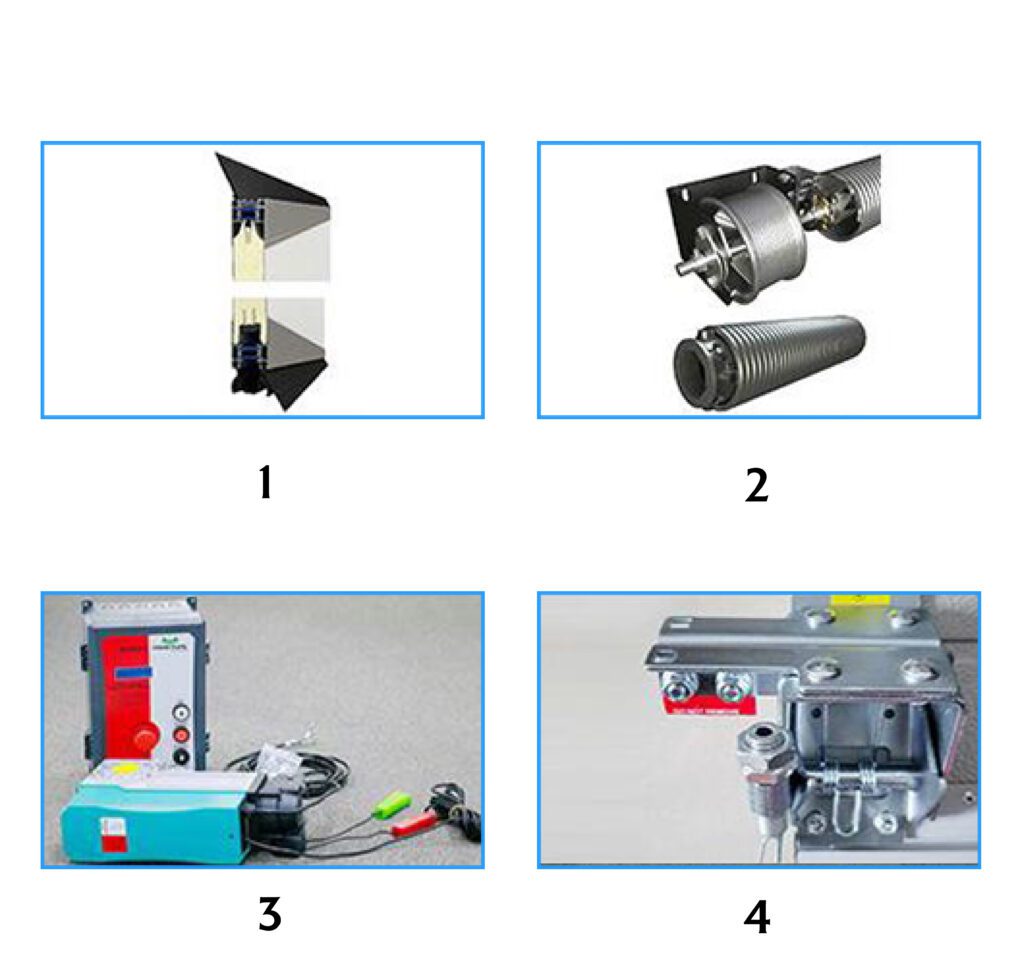

1. Door Panel Structure

EPDM sealing tapes and bottom seals are fitted on the top and both side guide rails. When the door is closed, the seals are completely closed. There is sealing rubber on the door panel grade interface to cut off the heat transfer and thus reduce the loss of energy.

2. Balance Device

The balance system is comprised of smooth functioning slide and hinge pulley. The slewing spring in the balance system is made of top tier quality spring steel, and undergoes surface treatment for rust and corrosion, enabling 30,000 cycles of spring life, with an order life of 5/100,000.

3. Control System

The competent system manages the door control with inversion intelligent control, and manages the door close and open with slow start and stop functions. It is more stable and durable. There are many unused expansion ports that serve different customization functionalities such as interlock linkage, and remote control communication.

4. Fall Arrest Device

The optional device for the protection of the torsion spring, when the spring breaks, the switch device opens and locks the door within 20cm range, and thus brings the door the body to fall. It is an anti-break and anti-fall protection device that works instantaneously.5. Doors and Panels

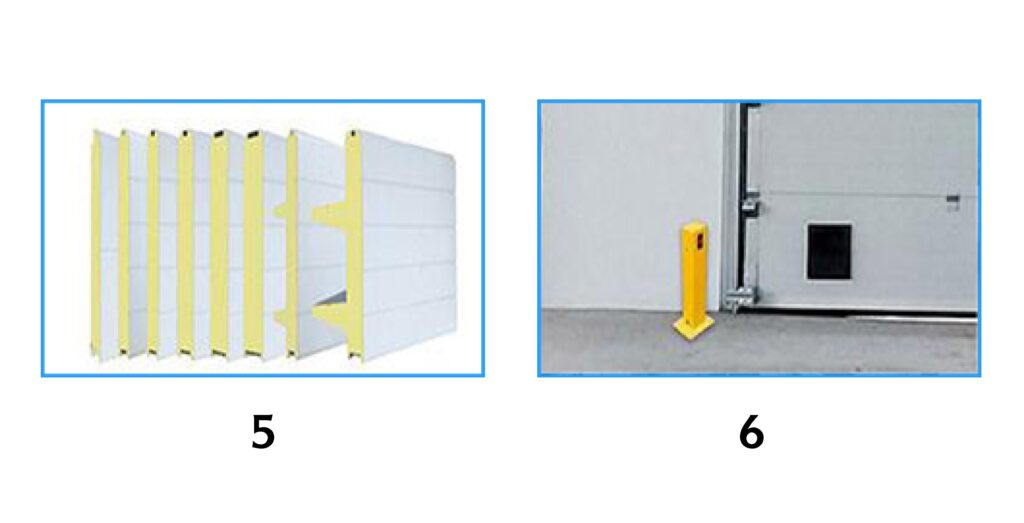

The door panels of series 40/43/50/60/75/80/43+60/51+120 (big rib) are filled with rigid polyurethane foam (density 45 KG/mᶟ) and impact resistant (245kg/m³) and do not pinch. They are tough and durable and possess thermal and acoustic insulation.

6. Safety Gear

The system offers rich add-on features such as window and door-in-door, small door and lifting method, wind-resistant accessories, remote opening and touchless control, colored door panels, and infrared and other automation safety induction.

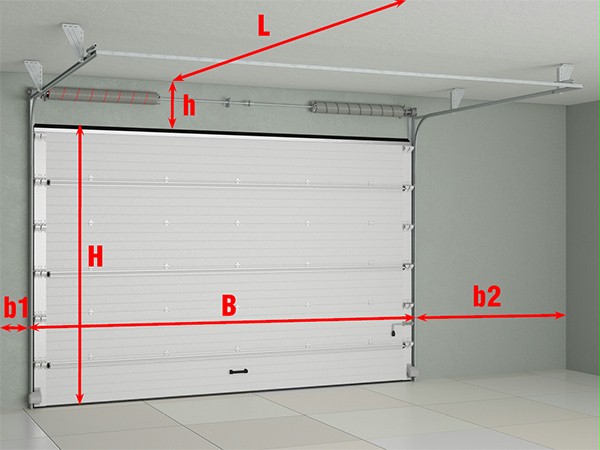

Installation Steps

Using data collection within an enclosed space, all parameters were examined in triplicate:

H – distance from the finished floor to the header’s underside whithin the door’s height.

B – distance measured between the left door stop to the right stop in the door’s width.

h – the dimension between the top of the door to the base of the ceiling; this value must be read at least 500 mm from the header underside.

b1/b2 – the dimension between the edges of the opening and the obstruction must be 150 mm.

L – the distance from the door’s face opening to the perpendicular obstruction within the room’s depth.

For both H and B, the most highest value was documented.

For h, b1, b2, and L, the lowest value was recorded.

Get A Quick Quotation Today

Applications of Loading Dock Door

Loading dock doors deliver secure, efficient access that streamlines loading and unloading operations in warehouses, manufacturing facilities, and logistics hubs—just a few examples. Thanks to robust door panels, smooth operating mechanisms, and reliable insulation performance, these doors ensure safety, durability, and energy efficiency throughout daily logistics activities. They stand out especially within the application zones listed below.

Resources on Loading Dock Door

Leading Industrial Sectional Door Manufacturers in China - SEPPES

Our company SEPPES is a professional Industrial Doors manufacturer. Products exported to 70 countries. Our products have multiple technical patents and EU CE certification with rich experience in fast shutter doors, rapid doors, high-speed roll-up doors, high-speed spiral doors, high-speed stacking doors, and PVC roller doors.

Why Choose Us

Loading Dock Doors enhance security, improve insulation, streamline workflows, and deliver safe, reliable access.

Cost Advantage and Value

Typical savings: 20–30% vs. foreign brands (factory-direct pricing, scale efficiencies).5 Reference params: EXW unit price ranges (PVC high-speed doors) ~$1,100–$2,500 depending on spec/size.4 Market context: Global dock doors market $3.5B (2024), projected $5.8B by 2033 (CAGR ~6.0%)

Certifications, Quality, and Reliability

SEPPES holds CE, SGS, UL, ISO9001/45001; 1M+ cycle tests; 30+ patents; exports to 60–70+ countries.3 Reference params: Sectional doors insulation U-value up to 0.5 W/m²K; wind resistance up to Class 5 (EN 12424); noise reduction up to 25 dB; 30,000–100,000+ cycle springs.5 Fortune 500 adoption signals quality (IKEA, Thermo Fisher, etc.).

Capacity, Lead Time, and Customization

Factory scale: 17,500–20,000 m² production area; 70+ door types; annual capacity cited up to ~$120–150M.435 Reference params: Custom panel thickness 40–60 mm PU; RAL color matching; manual/automated; IoT-ready controls; door sizes tailored per site.5 Process: size confirmation → quotation → fast delivery → install support (streamlined OEM/ODM flow).

Global Logistics and After-Sales Support

Exports to 60–70+ countries with established packaging/shipping practices; agents welcomed; insured shipments (e.g., product insurance backed by major Chinese insurers).35 Reference params: Door-to-door installation available in many markets; 1-year free maintenance service; 4,000+ foreign projects delivered.5 Practical totals: 5,000+ clients served; 3,800+ projects referenced on brand site.

Other Types of Industrial Doors You May Like

SEPPES International Trademark Certification

Since our founding, SEPPES has secured trademark registrations across several countries. Each new certification symbolizes growing worldwide recognition of our brand, which, in turn, reinforces our competitive position and expands our influence in international markets.

Welcome to SEPPES's Indsutrial Doors Factories

Frequently Ask Questions

Q: What are the main types of loading dock doors available?

A:Perhaps the most common garage door types are insulated sectional garage doors, which can be positioned either vertically or horizontally, roll-up doors that are much more durable and compact, and high-speed doors that boost productivity and climate control in areas with heavy traffic. Each subtype fulfills distinct functions, be it in terms of security or control of environments.

Q:How are loading dock doors sized and customized?

A: All nineteen doors can be tailored to the precise dimensions of the opening (both width and height). There are also various types of lifts that can be tailored to the available ceiling space, and a wide selection of any RAL color to go and strengthen corporate identity, and no vision panels or windows.

Q: What should I look for in terms of insulation and energy efficiency?

A:For optimal thermal control, look for insulated panels that are 40mm to 60mm thick, and filled with PU (Polyurethane) foam. A lower U-value also indicates improved insulation proper fusion helps reduce the energy consumption spent on heated or cooled facilities by keeping the temperature stable.

Q:How are doors rated for wind resistance and durability?

A:Durability is often assessed by the torsion spring’s cycle life which can be anywhere from 30,000 to 100,000 cycles. Wind load resistance is rated using the scribing standard like EN 12424, the higher the class the more the door can withstand the wind and its pressure which is vital in outer facing docks.

Q:What are the standard safety features for loading dock doors?

A:Important safety features include the reversal feature alongside photo-eye darts that scan the pathway of the closing door. Doors also have a fall-arrest system, which stops the door from falling if the cable breaks. There is a also a manual release mechanism to use the door system when electricity is not available.

Q: What automation and control options are available?

A:Modern doors have powerful controls, such as a VFD (Variable Frequency Drive), that is capable of executing a soft-start and soft-stop to minimize wear. There are also controls that can interlock with dock levelers, scan remote, and are connected to IoT (Building Management Systems).

Q:What site preparations are needed for installation?

A: Complete installation of the door requires a sufficient amount of side room and headroom clearance. The floor also needs to be leveled. The door should be able to integrate with the dock shelter and leveler to provide effective weatherproofing.

Q: What maintenance is required for loading dock doors?

A:The safety maintenance includes testing safety features and seals for wear and tear. More common wear parts, such as springs and cables, can significantly reduce the downtime.

Q: What international certifications should I look for?

A:Various regions’ markets are bound by key certifications, which scrutinize safety and quality compliance of products. International and European regulations, for instance, require a CE mark for compliance, proof of UL listing for North American, and ISO 9001 for quality management systems of manufacturing silos.

Q:How are shipping, lead times, and after-sales support handled?

A:Freight is usually done under normal Incoterms (e.g. FOB, CIF), whilst for each particular order, production lead times depend primarily on order volume and customization. Suppliers of good repute cater to all after-sale needs, covering installation, warranty specifics, and a high level of responsive technical assistance.