In modern construction projects, steel structure buildings have become the preferred structural form for many projects due to their advantages of light weight, short construction period, environmental protection and energy saving. With the development of industrialization and globalization. There is an increasing demand for steel building projects, especially in areas such as warehousing and logistics and production plants. And in these projects, efficient industrial doors and loading dock equipment are an important part of improving overall operational efficiency. This article will take an in-depth look at the use of these systems in steel buildings and how they can help companies increase productivity and reduce costs.

1. What are industrial doors and loading dock equipment?

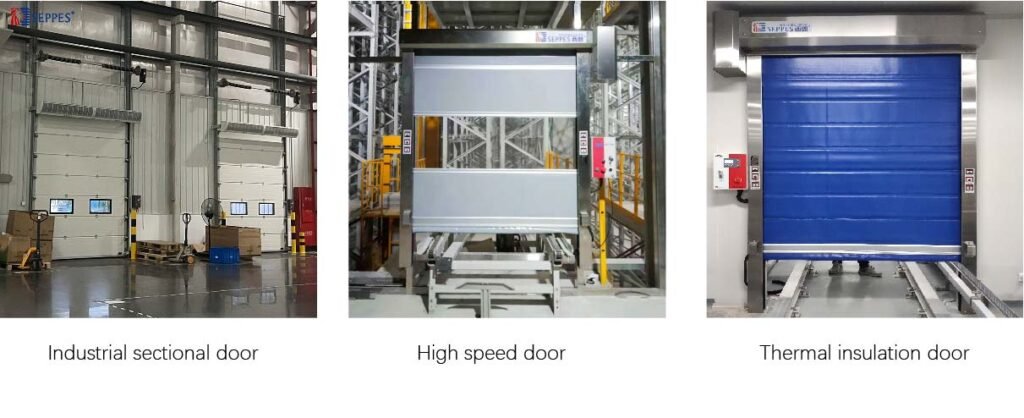

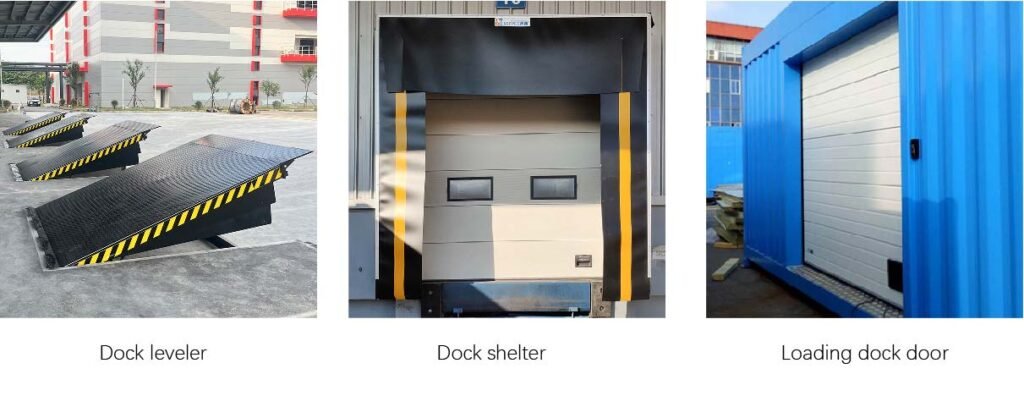

Industrial doors and loading dock equipment are an indispensable part of modern steel buildings. Industrial doors mainly include Industrial Sectional Door, High Speed Door, Thermal Insulation Door, etc. They are characterized by high-frequency switching, strong sealing, energy-saving and high efficiency. And are suitable for the frequent operation environment of goods in and out. The loading and unloading system includes Dock Leveler, Dock Shelter and Loading Dock Door. That ensure efficient loading and unloading of goods from vehicles to warehouses, and safeguard the safe transfer of goods.

The main types of industrial doors

Industrial Sectional Door: Sectional door design, flexible for warehousing and logistics, with excellent thermal and wind resistance.

High Speed Door: Fast opening and closing, saving time and reducing energy loss, suitable for high-frequency operation.

Thermal Insulation Door: with remarkable thermal insulation effect, commonly used in cold storage, food processing and other environments that require constant temperature control.

Main components of loading dock equipment

Dock Leveler: Adjusts the height difference between the truck and the warehouse floor to ensure the smooth and safe loading and unloading of goods.

Dock Shelter: Provides sealing protection between the wagon and the building, preventing the influence of external climate on the cargo loading and unloading process.

Loading Dock Door: Used in conjunction with industrial doors, it opens and closes quickly to ensure efficient loading and unloading.

2. Why do steel buildings need efficient industrial doors and loading dock equipment?

Choosing the right industrial doors and loading dock equipment for steel buildings is critical for several reasons:

1. Increase efficiency and optimize operational processes

The frequent flow of goods in steel buildings puts high demands on the response speed of doors and dock equipment. Industrial doors such as High Speed Door and Industrial Sectional Door can significantly reduce the waiting time for goods to enter and exit. And the addition of Dock Leveler ensures smooth docking of trucks and warehouses, reducing time wasted during loading and unloading, and maximizing operational efficiency. The addition of Dock Leveler ensures smooth docking of trucks and warehouses, reduces the time wasted during loading and unloading, and maximizes operational efficiency.

Project Case:

By installing High Speed Door with Dock Leveler system. A large food logistics warehouse in Belgium has increased the speed of goods in and out by 15%. In the peak flow of goods, the loading and unloading task that originally took 8 hours was shortened to 6.5 hours, greatly improving operational efficiency.

2. Energy saving and environmental protection, reducing energy costs

Since steel buildings often have large-span door structures, they may face a large amount of energy loss. By installing Thermal Insulation Door with good sealing and heat insulation. It can effectively prevent the loss of hot and cold air and reduce the energy consumption of air-conditioning and heating systems. While the use of Dock Shelter and Loading Dock Door ensures that the impact of the external climate on the internal environment is minimized during the loading and unloading process.

Project example:

By using Thermal Insulation Door and Dock Shelter, a cold chain logistics company in Germany saved about 20% of the energy consumption of cold air in one year, which helped the company realize a cost saving of more than 150,000 euros.

3. Enhanced security for safe operation

The infrared sensors and fall protection devices in the industrial doors ensure the safety of goods and people. In addition, the Dock Leveler system ensures a smooth connection between the truck and the warehouse. Avoiding the risk of goods falling and being damaged during loading and unloading. For those places that require high-precision operation and safety protection, industrial doors and loading/unloading systems can effectively reduce the probability of accidents.

Project example:

By introducing Industrial Sectional Door and Dock Leveler, a manufacturing plant in France has reduced the cases of cargo damage by 90% in two years. And effectively reduced the rate of work-related injuries of warehouse personnel, which has greatly improved the safety of the workplace.

3. How to choose the right industrial door and loading dock equipment for a steel project?

1. Optimal Configuration for Factory Warehouses

For steel factory warehouses, a combination of Industrial Sectional Door and Dock Leveler is recommended. The Sectional Door is able to cope with the entry and exit of goods from large areas, while the Dock Leveler ensures the safe transfer of goods by adjusting the height difference between the trucks and the warehouse.

Technical parameters:

Industrial Sectional Door: The thickness of the door body ranges from 40 to 80mm, with good wind resistance and heat insulation properties, and the opening and closing speed is 0.5-1 meter/second.

Dock Leveler: Height adjustment range of 300 to 500mm, maximum load capacity of 10 tons.

2. Efficient choice for logistics center

For the logistics industry, frequent loading and unloading operations require highly flexible doors and loading and unloading equipment, High Speed Door and Dock Shelter can provide fast access to ensure that the loading and unloading efficiency is maximized.

Technical specifications:

High Speed Door: opening and closing speed of 0.8-2.0 meters per second, the curtain material is high-strength PVC, wind resistance up to level 8.

Dock Shelter: sealing area reaches 90%, effectively blocking the influence of outside temperature.

3. The best choice for cold storage and food processing plant

For cold storage and food processing plants with high temperature control needs. The combination of Thermal Insulation Door and Loading Dock Door is recommended. Thermal Insulation Door can maintain a constant temperature and reduce energy loss, while the Loading Dock Door can ensure the rapid entry and exit of goods and maintain the stability of the internal environment.

Technical parameters:

Thermal Insulation Door: U-value below 1.0 W/m²K, opening and closing speed 0.8-1.5 m/sec.

Loading Dock Door: Highly efficient sealing, suitable for places with strict temperature control requirements.

4.Related Brand Recommendations

Choosing the right brand is crucial in steel construction projects. Some of the world’s leading brands such as SEPPES, Hörmann and ASSA ABLOY offer a wide range of industrial doors and loading dock systems to meet the needs of a variety of construction projects.

SEPPES has a reputation for providing highly efficient industrial doors and loading dock systems with excellent durability and energy efficiency. Especially for large steel construction projects. Brands such as HORMAN and ASSA ABLOY are widely recognized by customers around the world for their proven technology and comprehensive after-sales service.

Future Outlook

As steel building technology continues to evolve, future industrial doors and loading/unloading systems will become more intelligent and automated. For example, industrial doors will integrate more Internet of Things (IoT) features for remote control and real-time monitoring to optimize the operational efficiency of the entire building. Meanwhile, loading and unloading systems will evolve toward greater efficiency and safety. Future loading and unloading platforms will be more intelligent, able to automatically adjust the height, reduce human operation. And further improve the safety and efficiency of cargo loading and unloading.

Companies will focus more on energy saving and environmental protection in the coming years. Further reducing energy consumption and carbon footprint by using more efficient doors and loading/unloading systems. Steel construction projects around the world will rely on efficient doors and loading/unloading systems to meet increasingly stringent environmental regulations and operational requirements.

FAQ

1.What is an Industrial Sectional Door?

An Industrial Sectional Door is an industrial door that consists of sectional panels that are highly flexible and durable. And are suitable for a wide range of industrial locations, especially where large areas need to be opened and closed.

2.How to choose the right loading dock?

The choice of loading and unloading platform needs to be customized according to the type of goods, vehicle height and warehouse floor conditions. Common loading and unloading platforms include hydraulic and mechanical platforms. Which can flexibly adjust the height to ensure the safe loading and unloading of goods.

3.How are industrial doors energy efficient?

High-efficiency industrial doors such as Thermal Insulation Door reduce heat loss caused by indoor/outdoor temperature difference through its good insulation performance, reducing energy consumption. And are suitable for environments with stringent temperature requirements, such as cold storage and food processing plants.

4.Why is there a high demand for industrial doors and loading/unloading systems in steel construction projects?

Steel structure buildings are mostly used in logistics, warehousing and other high-frequency workplaces. The fast opening and closing function of industrial doors and the efficiency improvement of loading and unloading systems can help enterprises to significantly improve work efficiency and reduce operation time and energy consumption.