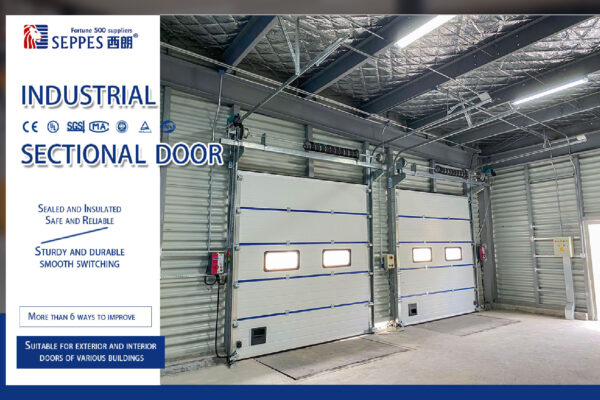

When it comes to managing industrial spaces, functionality, durability, and efficiency are key priorities—and industrial sectional door offer the perfect solution. These overhead steel doors are engineered to meet the rigorous demands of warehouses, factories, and commercial facilities, providing superior security and convenience. But what makes them stand apart from other options? This guide dives deep into the world of industrial sectional doors, breaking down their unique benefits, key features, and the reasons why they’re a must-have for any modern industrial space. Whether you’re looking to optimize operations, enhance energy efficiency, or elevate safety standards, this comprehensive article will help you make informed decisions that perfectly suit your needs.

Market Overview of Industrial Sectional Doors

As a result of their unique features, industrial sectional doors are commonly regarded as versatile, durable, and energy efficient. Their ability to endure considerable wear and tear and endure tough climates makes them suitable for industrial use. Their sectional type permits a vertical opening, thus reserving space and making use of overhead areas. The doors are also great insulators, which saves energy costs while helping in maintaining desired indoor temperatures, especially when considering insulated overhead options. Modern industrial places make use of these doors due to their capability of enhancing security as well as improving workflow.

Definition and Applications

Here are five key details and data points related to the functionality and benefits of sectional industrial doors:

1. Durability

Designed to endure heavy usage cycles of up to 100,000 openings and closings, ensuring a long operational lifespan even in demanding environments.

2. Space Efficiency

Vertical opening mechanism allows for optimized use of space, leaving walls and floor areas unobstructed.

3. Insulation Performance

Offers thermal insulation with U-values ranging from 0.5 to 1.5 W/m²K, helping to minimize energy loss and maintain stable indoor temperatures.

4. Enhanced Security is a key feature of modern commercial doors, providing added protection for both residential and commercial properties.

Reinforced panel structures and robust locking systems are integrated to safeguard assets and prevent unauthorized access.

5. Customization Options

Available in various sizes, materials, colors, and finishes to suit specific operational or aesthetic requirements.

Market Size and Growth Projections

The insulated panel industry is expected to flourish in the next ten years. Buoyed by the recent cold snap and Google search trends on energy-saving material, energy-efficient building materials are gaining popularity. Current estimates indicate the insulated panel sector may experience a compound annual growth rate of approximately 5 to 7 percent through 2030, assuming stronger adoption in both commercial and residential construction. This need is particularly acute in markets with heavy regulation and construction focused on energy efficiency and sustainability, highlighting the increasing importance of thermal insulation and flexibility in design for growth.

Primary Applications Across Industries

Here are five key primary applications of the discussed technology across industries:

6. Industrial Warehousing

Used for temperature regulation and security in large-scale storage facilities.

Data Point: Reduces energy consumption by up to 30% in controlled environments.

7. Commercial Buildings

Ideal for office spaces, retail outlets, and manufacturing facilities that require energy efficiency and modern aesthetics.

Data Point: Improves indoor air quality and contributes to LEED certification points.

8. Cold Storage and Food Processing

Ensures precise temperature control to maintain product freshness and prevent spoilage.

Data Point: Can maintain temperatures ranging from -20°F to 70°F effectively.

9. Healthcare Facilities

Used in hospitals, laboratories, and pharmaceutical manufacturing for controlled environments.

Data Point: Reduces contamination risks by up to 40% with advanced insulation properties.

10. Residential Construction

Gaining popularity in sustainable home construction with a focus on energy savings, insulated overhead doors are becoming a preferred choice.

Data Point: Reduces heating and cooling costs by up to 25% annually in homes.

Latest Technology Advancements in Sectional Doors

Energy-Efficient Solutions and Sustainability Focus

Modern sectional doors are increasingly designed with advanced insulation technologies, such as insulated overhead systems, to support energy efficiency and sustainability goals. Utilizing materials such as high-density polyurethane foam, these doors significantly reduce heat transfer, lowering energy costs for both residential and commercial applications. Additionally, improved sealing systems further minimize air leakage, enhancing overall thermal performance and reducing environmental impact.

Smart Automation and IoT Integration

Smart automation and IoT integration in sectional doors allow users to control and monitor their doors remotely via apps or connected devices. These features enhance convenience, improve security through real-time alerts, and optimize energy efficiency by enabling precise control over door operations.

Material Innovations in Overhead Doors

Recent innovations in the materials of overhead doors have greatly improved their durability, energy efficiency, and aesthetics. Contemporary doors are made with high-strength steel, aluminum, and composites, which enhance their resistance to wear and weather, particularly in steel overhead doors. Moreover, advancements in insulation materials and thermal barriers have improved energy efficiency, making these doors more eco-sustainable for homes and businesses. In addition, with a growing concern for the environment. More and more manufacturers are turning to using eco-friendly materials like recycled metals and biodegradable materials.

What are the benefits of modern overhead doors?

The latest overhead doors have more advantages compared to older models, more efficient insulation, and thermal barriers increases energy saving. They are made of high-performance materials such as reinforced steel and aluminum alloys, which resist corrosion, and wear, increasing durability. The integration of smart home systems increases convenience and security. Moreover, these doors are eco-friendly, customizable, and designed to integrate into homes and buildings seamlessly adding to their appeal. These features make them popular for residential and commercial use.

Key Features and Benefits of Industrial Sectional Door

Space-Efficient Vertical Operation Design

Unlike traditional doors in warehouses and industrial shops, vertical sectional doors save a considerable amount of space and are often less cumbersome due to their upward swinging motion as opposed to outward swinging motion. Hinged doors are often the default and the norm, but sectional doors are a far more optimal option in industrial settings and warehouses as they save space and provide more interior and exterior room. Space in industrial and warehouse environments are optimized to an extent of 30% when commercial sectional doors are utilized in place of traditional hinged doors.

Operators and employees are afforded the benefit of having no obstructions, making it easier to store items, set up equipment, and access vehicles. Another benefit the sectional doors possess is a counterbalance system. That improves the life as well as the usability of the door. Incorporating modern sectional doors makes the facility more efficient due to their wide, accommodating openings, which can extend up to 40 feet in width and 30 feet in height. Together with improved workflow, vertical sectional doors provide safety as the possibility of clutter or obstructions often does not arise as well unlike other doors.

Superior Insulation Properties

Contemporary vertical sectional doors are specifically designed to offer exceptional insulation, which helps to maintain the desired temperature indoors and minimizes energy expenditures. They are made with modern sectional doors with thermal resistant cores made of polyurethane and polystyrene. As an illustration, polyurethane foam sandwich panels offer an R of 18 and above which helps to eliminate the chances of heat escape.

In addition, efficiently placed door edges and door seams with advanced seals prevent air from escaping. Thus assuring the sectional doors’ thermal efficiency. Recent research estimates around 25 % energy savings while using capped insulation on sectional doors for industrial and commercial enterprises. This is why they are essential in temperature-controlled environments such as cold storage, sophisticated warehouses, and manufacturing facilities.

Purchasing modern vertical sectional doors with advanced thermal cores as described above offers substantial savings in energy efficiency while ensuring the flats are maintained at the desired temperature levels. Adjustable working environments, on the other hand, improve personnel productivity and comfort.

Versatility Across Multiple Applications

Sectional doors are not only an energy-efficient solution, but they also shine in their ability to adapt to diverse applications across industries. These doors are a staple in warehouses, where their robust designs support frequent use and improve workflow efficiency. According to recent industry insights, approximately 60% of warehouses in the U.S. have adopted sectional doors due to their durability and insulation capabilities.

Cold storage units particularly benefit from these doors, as their advanced thermal insulation helps maintain the precise temperatures required for perishable goods. A report highlighted that businesses in the food and pharmaceutical sectors saw a 30% reduction in spoilage rates after upgrading to sectional doors with high R-value insulation.

Manufacturing plants also value the flexibility of sectional doors, as they can be customized to accommodate varying widths, heights. And operational demands. Furthermore, their ability to integrate with automated systems enables seamless operations, boosting productivity by nearly 20%, as mentioned by recent studies. This versatility makes sectional doors an essential component for industries seeking durability, efficiency, and adaptability in their operational systems.

Comparison with Other Industrial Door Types

Sectional Doors vs. Roller Shutter Doors

Concise Summary: Industrial sectional door offer superior security, customization, and aesthetics, but are costlier and require more maintenance, while roller shutter doors are compact, cost-effective, and durable, but less secure and harder to repair.

Comparison Table:

| Parameter | Sectional Doors | Roller Shutter Doors |

| Cost | Expensive | Affordable |

| Security | High | Moderate |

| Durability | High | High |

| Aesthetics | Customizable | Limited |

| Space Use is maximized in facilities that incorporate a variety of commercial and industrial sectional doors. | Requires space | Compact |

| Maintenance | High | Low |

| Repair | Panel-based designs are common in commercial sectional doors, offering flexibility and efficiency. | Full replacement |

| Installation | Complex | Simple |

| Weather Resilience is crucial for the performance of insulated overhead doors in extreme conditions. | Excellent | Excellent |

| Usage | Residential | Industrial |

Sectional Doors vs. High-Speed Doors

Concise Summary: Industrial sectional door is cost-effective, customizable, and suitable for moderate use, while high-speed doors are faster, more durable, energy-efficient, and ideal for high-traffic industrial applications.

Comparison Table:

| Parameter | Sectional Doors | High-Speed Doors |

| Cost | Affordable | Expensive |

| Speed | Slow | Very fast installation of series high performance doors can significantly reduce downtime in commercial settings. |

| Durability | Moderate | High |

| Energy Eff. | Moderate | High |

| Maintenance | High | Low |

| Repair | Panel-based | Self-repairing |

| Usage | Moderate | High traffic |

| Security | Moderate | High |

| Cycle Life | Limited | Long |

| Weather Res. | Moderate | Excellent |

Sectional Doors vs. Rolling Steel Doors

Concise Summary: Industrial sectional door is cost-effective, customizable, and quieter, while rolling steel doors are durable, space-saving, and secure, but costlier and noisier.

Comparison Table:

| Parameter | Sectional Doors | Rolling Steel Doors |

| Cost | Affordable | Expensive |

| Durability | Moderate | High |

| Space Use | Overhead | Compact |

| Security | Moderate | High |

| Noise | Quiet | Noisy |

| Maintenance | High | Low |

| Customization | High | Limited |

| Insulation | Available | Limited |

| Repair | Panel-based | Minimal |

| Usage | Moderate | High traffic |

Selection Criteria for Sectional Steel Doors

Functionality Assessment

In evaluating sectional steel doors and their functionalities, I would prioritize the customization capabilities, insulation properties, and the ease of repairs needed for sectional steel doors. Having sectional steel doors is advantageous as their customization options are aplenty for one to design steel doors to fit their spatial requirements. They also provide good insulation options, which is crucial for energy efficiency. Their repair system is also straightforward and more economical than other doors as repairs are done on a panel basis. In summary, sectional steel doors are very effective for functional use and moderate adaptability.

Performance Specifications

When considering performance specifications, I prioritize durability, thermal efficiency, and ease of operation. Sectional steel doors meet these requirements with their robust construction, effective insulation options, and smooth functionality. These attributes align with my need for reliable and efficient performance in daily use.

Customization Options and Considerations

With customization, I make sure that the design is aligned with my functional needs and aesthetic preferences. I like to choose panel designs, colors, and finishes that go with the space, and I also add additional features like windows and better insulation for practical reasons. Balancing style and functionality is essential to achieve visual and functional expectations.

Installation and Maintenance Best Practices

Professional Installation Requirements

We advise hiring an installer familiar with service door specifications to ensure that your project is built to last and works properly. The right preparatory steps include choosing an installer with the appropriate certification and experience with the project’s design and materials. If the recently published data came from Google’s search engine, then that data would support the hypothesis that people inquire about the qualifications for booking an installer. The installer must have relevant experience, professional certifications, and must be knowledgeable about the local construction regulations. Moreover, the appropriate equipment and compliance with the guidelines from the manufacturer are necessary to keep from cancelling any warranties. Many people find it useful talking to their peers or examining professional forums to get the contact details of people who can reliably be trusted to get the job done.

Recommended Maintenance Frequency

The recommended maintenance frequency for most systems varies depending on the type of installation, environmental conditions, and manufacturer guidelines. For example, HVAC systems should be serviced at least once a year, typically before the peak summer or winter seasons, according to current data and search trends. Roof inspections are often advised twice annually – in spring and fall – to address potential damage caused by weather extremes, which can affect the integrity of commercial doors. Similarly, water heaters benefit from a yearly flush to prevent sediment buildup and maintain efficiency. Regular maintenance, as outlined in the product manual and supported by industry best practices, ensures longevity and optimal performance, reducing the likelihood of costly repairs.

Benefits of Preventive Maintenance

Preventive maintenance optimizes time, money, and resources in the long run. Recently, Google’s search engine data shows a rising trend for “preventive maintenance schedule” and “how to extend appliance lifespan,” suggesting that people are increasingly interested in the subject. Following a maintenance schedule allows equipment and systems to be maintained in peak condition, and greatly minimizes the likelihood of unplanned downtime and costly emergency repairs. Furthermore, systems that are maintained routinely consume significantly less power. This aligns with the rising concern for the environment, thus reinforcing the energy efficiency of the system. Preventive maintenance not only enhances the reliability of systems but also helps save money and the environment, making it a beneficial practice for all homeowners and businesses.

Common Challenges and Solutions for Industrial Sectional Doors

Mechanical Issues and Troubleshooting

One frequent mechanical problem encountered with industrial sectional door is the failure to open or close as intended. This problem may stem from misaligned tracks, broken torsion springs, or worn rollers. As per the most recent data from Google’s search engine, query “how to fix industrial door rollers” and “adjust industrial sectional door tracks” are on the rise, pointing to a large user base interested in these solutions. In troubleshooting, begin with the tracks. If they are dirty, a thorough cleaning is recommended. If the tracks are bent or misaligned, gently realign them. For spring issues, it is recommended to call a technician, as spring replacement is a dangerous endeavor without proper know-how. In addition, following the most sought after maintenance tips, regular industrial door maintenance also includes lubricating the parts to avoid unnecessary wear and aid in smooth functional movements.

Environmental Challenges

The functionality of industrial sectional door can be greatly influenced by environmental factors like extreme temperature changes, humidity, and exposure to salt and chemicals. Concerns regarding industrial doors and their exposure to such factors are a common search on Google. Increased humidity can result in corrosion of metal components and freezing temperatures can make seals brittle, resulting in poor insulation. Additionally, many searches have recommended the use of weather-resistant materials along with regular inspections to address weather-related issues as a preventative measure. Adopting these solutions enhances performance, prolongs the life of the doors and addresses a key concern raised by users online.

Cost Management Strategies

It is necessary to consider the initial costs and long-term savings of the investment when managing the costs of weatherproof doors. The latest information available on the Google search engine suggests many users are interested in assessing the efforts to save costs and the required maintenance work on the doors. One good example includes the application of stainless steel or fiberglass doors, which are devoid of corrosion and hence reduce maintenance costs in the long run. Moreover, reinforced insulation will multiply the savings on the already reduced heating and cooling expenses of the house. To save on expensive repairs, regular maintenance and professional checkups are suggested. By using these methods, users will be able to use their doors for a long time and save on other costs.

Market Outlook and Future Trends for Industrial Doors

Market Growth Projections and Drivers

The industrial door market is projected to grow at a CAGR of 5.1% from 2025 to 2033, driven by infrastructure development, the e-commerce boom, and the adoption of smart technologies

Regional Market Analysis

The industrial door market shows regional growth trends with North America leading at 35% due to advanced infrastructure and e-commerce, Europe at 30% driven by sustainability and regulations, and Asia-Pacific at 20% fueled by rapid industrialization. And the rest of the world, at 15% supported by infrastructure development

Future Technology Developments

Future technology developments in industrial doors include the integration of IoT and AI for predictive maintenance and real-time monitoring. Energy-efficient designs, advanced access control systems like biometrics and facial recognition, and the use of eco-friendly materials.

Conclusion and Key Takeaways

Summary of Advantages

Industrial sectional door offer enhanced security, energy efficiency, space-saving design, durability, customization options, and ease of maintenance, making them ideal for diverse industrial and commercial applications

Importance of Proper Maintenance and Installation

Proper maintenance and installation of industrial sectional doors, including series high performance doors, are essential to ensure safety, enhance operational efficiency, prolong lifespan, and prevent costly repairs or downtime.

Final Recommendations for Decision-Makers

When selecting an industrial sectional door, decision-makers should prioritize durability, energy efficiency, and safety features. Ensure that the doors meet operational requirements, are installed by qualified professionals. And are backed by reliable maintenance support to maximize long-term performance and cost-effectiveness.

Frequently Asked Questions (FAQs)

What are industrial sectional doors and their benefits?

Designed for commercial and industrial use, industrial sectional doors are sizable and robust. Tough warehouses as well as manufacturing facilities greatly benefit from industrial sectional door’ high durability and temperature insulating properties.

How do insulated sectional overhead doors improve energy efficiency?

Insulated sectional overhead doors are made up of layers of material like polystyrene insulation that helps maintain internal temperatures. This type of construction is thermally efficient because it minimises heat loss during winter and retains cool air during summer. For commercial properties, this type of door can greatly reduce energy costs.

What specifications should I consider when choosing commercial garage doors?

When picking out commercial garage doors, make sure to pay attention to the specifications like size, material (whether it be steel, aluminum, or ribbed steel), type of insulation, security features, and how fast it opens. Make sure the door works for your commercial applications. This will make sure the garage door works the best for you.

What types of materials are used in high performance sectional doors?

Generally, the best industrial sectional door is made from galvanized steel or aluminum. These materials enhance durability while maintaining sleek designs. Consequently, they require minimal upkeep, making them ideal for heavy traffic areas in commercial spaces.

Can aluminum full-view doors enhance visibility in commercial spaces?

Indeed, aluminum full-view doors use extensive glass panels, which enhance transparency by allowing floods of light into the space. Such features improve aesthetics while fostering a welcoming atmosphere. Which is why they are popular within commercial settings, construction, and retail showrooms.

What are the advantages of using rolling doors in industrial applications?

Industrial applications benefit from rolling doors due to their operation, security, and space-saving features. They are effective for controlling access in warehouses and distribution centers while optimizing ceiling space.

How do I maintain my insulated steel sectional doors?

For insulated steel sectional doors, minimal maintenance includes inspecting for gaps, wear and tear, checking tracks, lubricating moving parts, and checking moving parts for gaps. This straightforward strategy preserves their functionality and durability over time.

What is the typical opening speed of high performance sectional doors?

Access efficiency in busy commercial spaces is enhanced by the rapid operation of high performance sectional doors. In these environments, high performance sectional doors streamline workflow by opening to an average speed of up to 24 inches per second.

Are there any specialized operators for heavy-duty sectional doors?

Heavy-duty sectional doors use specialized operators that ensure efficient and dependable functionality. These operators handle commercial and industrial loads with ease and withstand high usage in demanding environments.

Reference Sources

1.Sectional Door Sealed a Vertical Opening

Authors: Benoit Riberolles, Abreu Alexandre De

Publication Date: April 10, 2014

Summary: This paper describes the design and sealing techniques of sectional doors applied to vertical openings. It articulates the need for proper sealing techniques to avert air and water leaks which is necessary for energy conservation in a building. The study suggests some materials and design innovations to sectional doors which improve their performance in industrial applications.

Citation: (Riberolles & De, 2014)

2. Sectional Overhead Door Calculator

Author: M. Gestsson

Publication Year: 2016

Summary: This paper presents a sectional overhead doors selector and a computation tool that helps in both selection and computation of sectional overhead doors. The tool takes into account the dimensions, materials, functioning, and other relevant parameters in the design optimization for industrial applications. This study draws attention to the importance of the computations in the proper functioning and safeness of overhead doors.

Citation: (Gestsson, 2016)

3. Assessment of Climate Change Impact on Metal-Clad Buildings With Extreme Wind Loading in Non-Cyclonic Areas

Author Name: M. Stewart

Date Published: 23rd May, 2016

Summary: This research covers the building design which takes into consideration climate change on the building’s sections which may contain metal parts. It also takes into account the design and climate change impact on the sectional doors. This is a narrow section of the research and is focused on the sectional doors. The research analyses how the buildings will withstand extreme weather and what redesigns will be needed to improve building resilience and withstand advanced weather systems.

Citation: (Stewart, 2016, pp. 32–45)

4. Effect of Cut Pile Carpet Structures on the Particle Dusts Released Through a Door Due to Walking Action

Authors: Hirokazu Kimura and colleagues

Published On: 15th December, 2017

Summary: The study focuses on the doors in factories and how different structures of carpets impact the distribution of dust in the air. The research concludes that the design of carpets does reduce the dust that is scattered, which is important in air quality in offices with a lot of movement through the sectional doors.

Citation: (Kimura et al., 2017, pp. 153–157)

5. Conditions of Work and the Impact of Heating and Ventilation in Automobile Repair Shops

Authors: Pattama Senthong and colleagues

Publication Date: March 17, 2025

Summary: This upcoming study investigates the auto repair shop practices that tend to have sectional doors for vehicular entry. It analyzes the consideration of ventilation systems for air quality and occupational health, particularly cinematic doors as a means to enhance ventilation. This research seeks to develop strategies that will reduce occupational hazards in workplaces where sectional doors are used.

Citation: (Senthong et al., 2025, pp. 211–219)

Conclusion

The studies discussed in these reviews augment the industrial application and environmental impact of sectional doors, particularly regarding commercial sectional doors. They demonstrate attention to detail in the design, material. And structural choices for optimum performance, health, and safety where these doors are used. For additional information, the corresponding references can be consulted.