Truck Restraint System

Truck Restrictor Product Introduction

Vertical Lift Truck Restrictor

The Vertical Lift Limiter is floor-mounted. The limiting device is operated by a control box installed indoors, and the vertical limiting hook pulls the truck’s anti-collision tailgate and fixes it to the loading/unloading platform.

SEPPES: Your Premier Manufacturer Of Truck Restraint System

SEPPES is a leading manufacturer of high-quality, Vertical Lift Truck Restrictors committed to providing exceptional products that enhance efficiency and security in various industries. Drawing inspiration from cutting-edge technology, we consistently deliver reliable and innovative door solutions.

Innovative technology

- Self-developed, designed and produced

- Simple and reliable structure, only need to do routine lubrication and maintenance on the axle

- Maximum lifting up to 254mm, applicable to a wide range of truck types

- Hydraulic drive enables the hook body to maintain continuous following and fixing of the truck when the height of the truck changes

- Galvanized coating inside and out and can be painted with warning colors

- Audible warning device

- Internally mounted control box and externally mounted signaling system

Components of the truck limited motion system

Mechanical locking assembly, made from a steel base, protects all components from damage due to weather, dust, and debris.

a. Stable operation even in harsh environments, and the advantages of simple operation and maintenance.

b.The limiting mechanism can withstand a maximum pulling force of 14.5 tons.

Self-developed control system.

a.High brightness LED traffic signal design for universal red and green lights.

b.The equipment uses PLC (Programmable Logic Controller) for system control, which effectively enhances the accurate and reliable operation of the equipment and enables interconnection and interlocking with other platform equipment.

c. When loading and unloading goods, the reliable design follows with the rise of the car.

Signal cueing system

1. LED lights are standard, LED lights have a long service life, and the voltage is powered by safe voltage (DC 24 volts).

2. LED indicator lights are used at the buttons to increase the degree of recognition of the operation and prevent misoperation in the dark environment.

3. External Signal Light System: Flashing red or green light all the time to prompt the truck driver whether it is safe to reverse into or out of the highway traffic lights with the same level of design as a bright waterproof low-voltage signal light system.

4. Internal Signal System: Flashing red or green light all the time to indicate whether the freight platform operator can safely carry out loading and unloading operations.

5. The internal signaling system flashes the opposite of the external signaling system.

6. AUDIO ALARM: An internal alarm device alerts the platform operator that the truck tailgate is not in its normal restricted position.

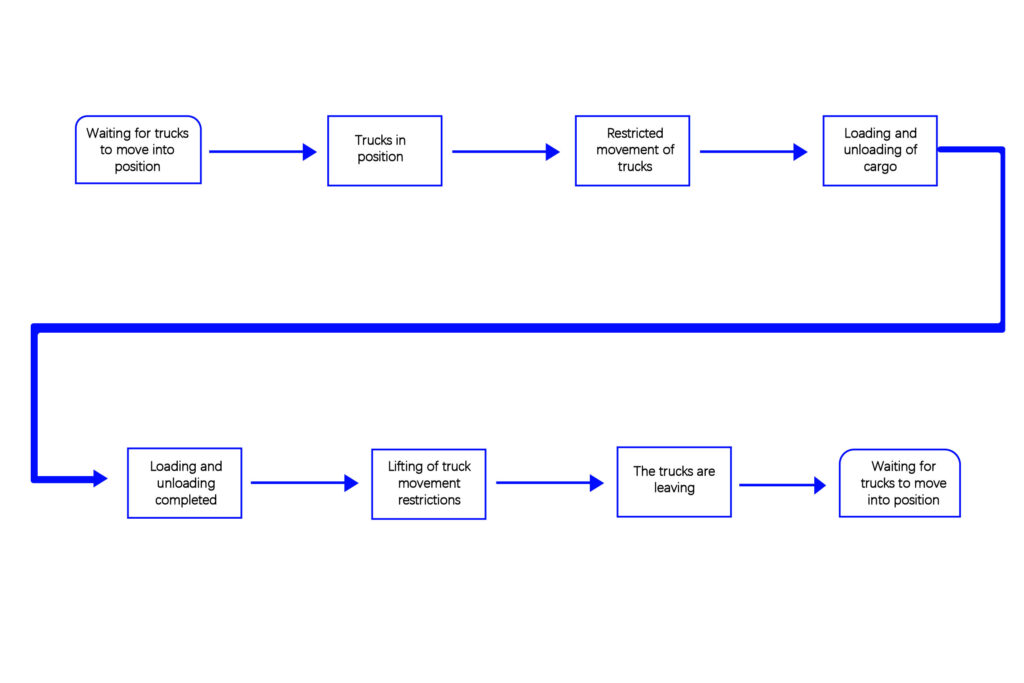

Truck Restrictor Workflow Description

1. When the truck is backed into the loading platform, the platform staff presses the locking button on the control panel to lift the limiter and secure the truck.

2. The LED indicator shows inner green/outer red, and the van is limited to moving. And it can withstand a pulling force of over 14.5 tons.

3. The limiter stays in contact with the crash bar and is automatically adjusted by the float of the truck to ensure that it is always effectively limiting during the loading/unloading operation.

4. When loading/unloading is complete, the platform operator presses the unlock button on the control panel to unlock the truck.

5. The LED signal light system will automatically adjust to the outer green/inner red traffic signal indication.

Get A Quick Quotation Today

Company Profile

SEPPES Door Industry (Suzhou) Co., Ltd. is a high-tech company focusing on the development, design, and manufacturing of industrial door technology, headquartered in Suzhou, China. We manufacture complete customized entrance door system solutions for industrial customers. Our main products include high-speed doors, automatic roller shutter doors, sectional doors, etc. All products comply with European industry standards and have obtained EU CE, international SGS, and ISO9001 quality management systems. Certification.

With professional products and a brand reputation, SEPPES has become a cooperative supplier of more than 60 Fortune 500 companies. Products are exported to more than 50 countries and regions including the European Union, Australia, the United States, Canada, France, Japan, Dubai, and Russia, and have provided products and technical solutions as well as multiple product safety guarantees for more than 3,200 corporate customers!

Customized design out of drawings

Understanding Demand

Prior to the start of the project, we will understand in detail the specific needs of the client for the high-speed doors, including the environment of use, functional requirements and, budget.

Customized Solutions

After clarifying the customer's needs, our professional design team will customize the design plan according to the actual situation and draw detailed drawings.

Design The Drawings

Our designs take into account the functionality, aesthetics, and security of high speed doors. Clients can suggest any changes to the design at this stage to ensure that the final solution is exactly as expected.

Efficient Manufacturing

Once the design drawings have been confirmed by the customer, our production department will begin manufacturing immediately. Our production equipment and process technology are advanced to ensure that each speed door meets the highest standards. During the production process, we strictly control every step to ensure product quality and delivery.

Safe Packaging And Transportation

After the products are manufactured, we will pack them tightly to ensure that they are not damaged during transportation. We cooperate with professional logistics companies to ensure that the products can be delivered to the customer’s designated place on time and safely.

The approximate time from order to production is 18 working days.

Satisfaction Feedback

Upon completion of the installation, we invite our customers to evaluate our products and services. We take customer feedback very seriously and use it to continually improve our products and services. Many of our customers have praised our high-performance speed doors for their outstanding performance in terms of energy saving and productivity improvement.

Colombian Clients

Logistics Company: "Since installing SEPPES's high-speed doors, our warehouse operations have greatly improved. The doors' high performance and reliability have significantly reduced the time for goods to move in and out, increasing customer satisfaction."

Southeast Asian Clients

Electronics Factory: "SEPPES's high-speed doors are perfect for our electronics production workshop. The doors' fast switching function helps us maintain a constant workshop temperature, ensuring product quality."

Australian Clients

Mining Company: "SEPPES's high-speed doors have played an important role in our mining facilities. The doors' high durability and quick response capability help maintain high operational efficiency even in harsh environments."

Russian Clients

Manufacturing Plant: "At our manufacturing plant in Russia, SEPPES's high-speed doors have significantly boosted our production efficiency. The doors' high performance and reliability excel even in cold environments."

We have authentic and authoritative certificates

Our Amazing Clients

We have exported to more than 65 countries and regions. Our powerful service internet and install team helps us build relationships with customers who come from Europe, Middle East, South America, and South East Asia.

China Leading High Speed Radar Motor Manufacturer and Supplier

SEPPES is committed to providing types of High Speed Door Sensor for your business.