Choosing the right High Speed Door to improve efficiency and safety

In modern industrial environments, high-speed doors are used in a wide range of applications where fast access, energy efficiency, and improved safety are required. As the demand for efficiency and safety continues to rise, High-Speed Doors have become indispensable pieces of equipment in the industrial sector. Depending on the requirements, speed doors can be categorized into various types, each playing a unique role in a specific environment.

This guide will introduce the various types of speed doors in detail, including different switching methods, door materials, functional requirements, drive methods, installation locations, application scenarios, etc., to help you choose the most suitable speed door solution according to the specific application requirements.

Distinguish according to the switching mode

The opening and closing mode of the fast door directly affects its opening and closing speed, applicable places, and operation mode. Common opening and closing methods include roll-up type, high-speed spiral type, stacking type, self-repairing type, etc. Each method is suitable for different needs.

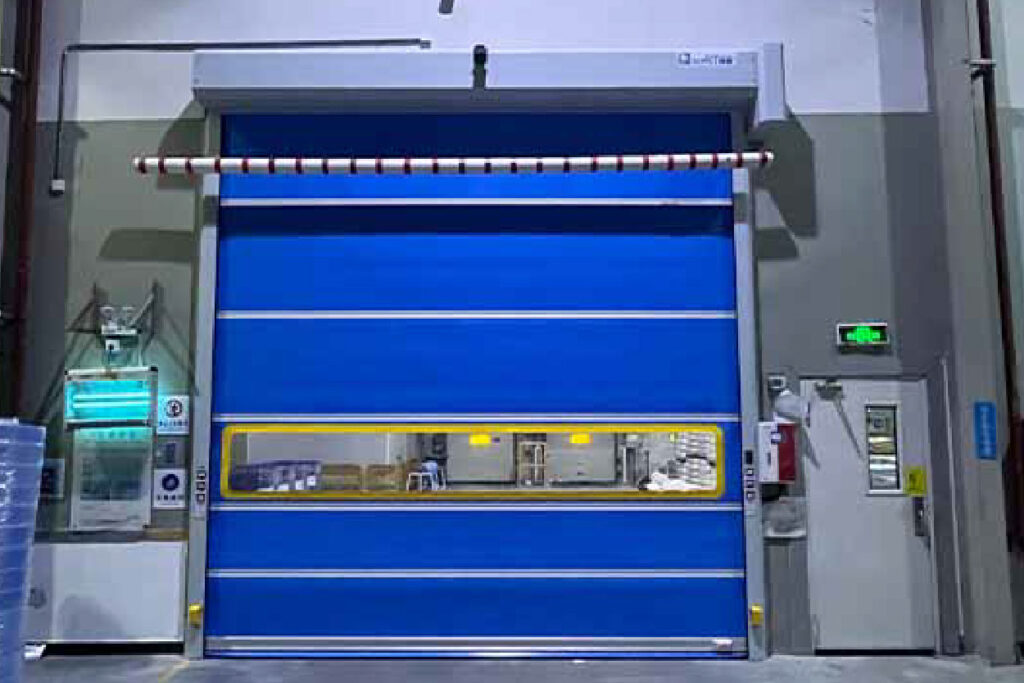

Roll-Up High Speed Door

Features:

Opening and closing speed: generally 0.8m/s – 2.0m/s, suitable for high-frequency and low-frequency use of the environment.

Door curtain material: usually uses PVC and polycarbonate, with good durability, UV resistance, and windproof performance.

Applicable places: suitable for warehouses, production workshops, logistics centers and other places that need to save space.

Advantages:

Fast switching, suitable for low to medium frequency use environment.

Provides a good seal to minimize air loss and temperature fluctuations.

Disadvantages:

May not be suitable for areas with large openings.

Spiral High Speed Door

Features:

Switching speed: usually 1.5m/s, the door body lifts along the spiral track.

Applicable places: suitable for high-frequency access environments, such as external warehouses, logistics areas.

Advantages:

High wind resistance, suitable for outdoor use.

High security, reduce the influence of external airflow, suitable for areas requiring high-frequency access.

Disadvantages:

Higher upfront investment, suitable for enterprises with more adequate budget.

Stacking High Speed Door

Features:

Opening and closing method: adopts sectional folding design, suitable for areas requiring large openings.

Applicable places: commonly used in large warehouses, airplane hangars, docks, etc.

Advantages:

Adapt to harsh environments, strong wind resistance.

With self-repair function, reduce downtime when the door is damaged.

Disadvantages:

Not applicable to places with small space.

Self Repair High Speed Door(High Speed Zipper Door)

Features:

Self-repair function: when the door body is hit or damaged, the door curtain can be automatically restored, reducing maintenance costs.

Applicable places: suitable for high-frequency use, equipment in and out of the place, such as warehousing and logistics, production lines and so on.

Advantages:

Reduce maintenance costs and improve work efficiency.

The automatic restoration function reduces downtime.

Disadvantages:

Higher cost, suitable for high-frequency use places.

| Door type | Switching speed | Applicable places | Advantages | Disadvantages | |

| High Speed Rolling Door | 0.8m/s – 2.0m/s | Warehouse, workshop, cold chain logistics | Fast switching, energy saving, good sealing | Not suitable for large opening areas |

| High Speed Spiral Door | 1.5m/s | High traffic external environment, high frequency | High wind resistance and safety | Higher upfront investment |

| Stacking High Speed Door | 0.6m/s – 1.2m/s | Large openings, airplane hangars, docks | Self-repairing, wind resistant | Suitable for large openings |

| Automatic Repair High Speed Door | 0.8m/s – 1.2m/s | High-frequency entry and exit areas | Reduced maintenance costs and downtime | Higher cost |

Distinguish according to the door body material

Door body material determines the strength, durability, and ability to adapt to the environment. Common materials include PVC, fabric, steel, and aluminum, each of which is suitable for different needs.

PVC High Speed Door

Features:

Material: PVC material with flexibility and abrasion resistance.

Applicable places: suitable for industrial places with low-temperature control requirements, such as food processing plants, warehousing, and logistics.

Advantages:

Low cost, easy to install.

Good UV resistance, suitable for indoor use.

Disadvantages:

Not suitable for places with high security requirements.

Fabric High Speed Door

Features:

Material: made of high-strength synthetic fabric, providing lightweight and strong durability.

Applicable places: suitable for areas with high-frequency opening and closing, such as logistics centers, temperature control, and places with low demand for clean environments.

Advantages:

Lightweight and durable for high frequency operation.

Adaptable to temperature-controlled environments and meets low cleanliness requirements.

Disadvantages:

Not suitable for environments with high security requirements.

Steel High Speed Door

Features:

Material: made of steel frame and panel with very high strength and impact resistance.

Applicable places: suitable for places requiring high safety and durability, such as workshops, ports, and dangerous goods warehouses.

Advantages:

Strong impact resistance, suitable for harsh environments.

High safety and durability.

Disadvantages:

Higher cost, need higher budget.

Aluminum Roller Shutter Door

Features:

Material: adopts aluminum alloy, which is lightweight and corrosion-resistant.

Applicable places: suitable for low-frequency use and lower requirements for temperature control, such as garages, stores, and so on.

Advantages:

Lightweight, easy to install and operate.

Strong corrosion resistance, suitable for indoor and outdoor use.

Disadvantages:

Less impact resistant compared to steel doors.

| Material type | Advantages | Applicable places | Disadvantages | |

| PVC High Speed Door | Low cost, UV resistant, lightweight | Logistics warehouses, food processing plants | Poor impact resistance |

| Fabric High Speed Door | Lightweight, durable, suitable for high frequency use | Temperature-controlled environments, clean rooms | Not suitable for high security areas |

| Steel High Speed Door | High strength and impact resistance | Places with high security requirements | Higher cost |

| Aluminum Alloy High Speed Rolling Door | Lightweight, corrosion resistant | Garages, stores | Less impact resistant than steel doors |

Distinguish according to function

The function is a major feature of the high-speed door, according to different functional requirements, the high-speed door can be divided into heat-insulating type, fire prevention type, transparent type, equipment protection type, and so on.

Insulated High Speed Door

Features:

Function: with heat insulation function, suitable for cold storage, food processing plants, pharmaceutical factories, and other places with high-temperature control requirements.

Applicable places: suitable for cold chain logistics, temperature-controlled warehouses, etc.

Advantages:

Energy saving, reduce temperature loss.

Strong sealing

Transparent High Speed Door

Features:

Function: using transparent PVC film or polycarbonate can improve visibility and reduce the visual blockage to the surrounding environment.

Applicable places: suitable for stores, garages, and places that need a better view.

Advantages:

Provides a good view and improves safety.

Aesthetically pleasing and suitable for retail stores, display areas, and other locations.

Disadvantages:

For environments with high-security needs, transparency may pose some risks.

Fire Rated High Speed Door

Features:

Function: adopting fire-resistant material, it can effectively isolate the fire source and smoke, suitable for high-risk environments or factories that need fire protection.

Applicable places: such as chemical warehouses, high-risk factories, and hazardous material storage areas.

Advantages:

The fireproof function effectively isolates the fire source and smoke.

Enhances safety and avoids the spread of fire.

Disadvantages:

Higher price, suitable for high-risk environment.

Machine Protection High Speed Door

Features:

Function: this door body is designed to protect equipment from external damage and ensure the safety of operators.

Applicable places: such as machining workshop, assembly line, and other high-risk environment.

Advantages:

Anti-collision, anti-impact, protect equipment and personnel safety.

Provides a good dustproof and waterproof function to adapt to the harsh environment.

Disadvantages:

Highly functional, high price.

| Function Type | Applicable places | Advantages | Disadvantages | |

| Insulated High Speed Door | Cold chain logistics, food processing plants | Energy efficient and good temperature control | Higher installation costs |

| Transparent High Speed Door | Stores, garages, retail environments | Provides a good view and improves safety | Not many areas for high security needs |

| Fire-Rated High Speed Door | High risk environments, hazardous materials warehouses | Strong fire and smoke protection | Higher cost |

| Equipment protection High Speed Door | Machine shops, assembly lines | Anti-collision, anti-impact, protection of equipment and personnel | Higher price |

Distinguished according to the installation location

According to the installation location, the high-speed door can be divided into indoor, high-speed door, and outdoor high-speed doors, different locations of the door body in the design of different requirements, especially the performance of wind and water resistance.

Interior High Speed Door

Features:

Suitable for indoor environments, such as production workshops, clean rooms, warehouses, etc.

Providing better sealing and sound insulation effects can effectively reduce pollution and noise indoors and outdoor.

Advantages:

Space saving, easy to operate, good sealing.

Provide a clean and quiet environment suitable for places with high environmental requirements.

Disadvantages:

Less influence on external weather, not suitable for environments with high wind and rain.

Exterior High Speed Door

Features:

Suitable for exterior environments such as warehouses, garages, loading docks, etc.

Needs to be wind and water-resistant and use stronger materials such as steel and aluminum.

Advantages:

Windproof, waterproof, adapt to external severe weather conditions.

Strong durability, adapt to the external frequent switch use of the place.

Disadvantages:

Higher cost, higher installation requirements.

| Installation Location | Applicable places | Advantages | Disadvantages | |

| Indoor High Speed Door | Production workshops, clean rooms, warehouses | Good sealing, space saving, low noise | Not suitable for external environments |

| Outdoor High Speed Door | Warehouse doors, garage doors, loading and unloading areas | Windproof, waterproof, adaptable to harsh environments | Higher cost and complicated installation |

Distinguish according to application scenarios

Rapid doors can be categorized into clean room doors, high flow doors, etc., according to different application scenarios, and are designed to meet the needs of specific places.

Clean Room High Speed Door

Features:

Design features: high sealing, low noise, high speed switching and other features, suitable for environments that require strict control of pollution.

Applicable places: such as pharmaceutical factories, food processing, electronics manufacturing, etc.

Advantages:

Provides a clean environment and prevents contaminants from entering.

High-speed switching improves productivity and is suitable for environments with high cleanliness requirements.

Disadvantages:

Higher price, suitable for places with very high cleanliness requirements.

High Traffic High Speed Door

Features:

Suitable for areas with frequent access, such as logistics warehouses, production lines, loading and unloading areas.

Higher switching speed, adapted to high-frequency switching environment.

Advantages:

Improve passage efficiency and reduce traffic congestion.

Suitable for logistics or production areas with high traffic flow and high durability.

Disadvantages:

Higher cost, suitable for large-scale use.

| Application Scenarios | Applicable industries | Main Features | Prices | |

| Cleanroom High Speed Door | Pharmaceuticals, electronics manufacturing, food processing | High sealing, anti-pollution, low noise | High |

| High Traffic High Speed Door | Logistics warehouses, production lines, airports | High frequency use, high switching speed | Medium-high |

Conclusion: how to choose the best types of high speed doors?

Choosing the right types of high speed doors is crucial to improving the efficiency of your business, reducing operational costs, and enhancing security. When choosing a speedy door, you need to comprehensively consider factors such as opening and closing methods, door material, function, drive method, installation location, and application scenarios.

If your working environment requires fast access, such as logistics warehouses, production lines, cargo loading and unloading areas, Roll-Up High-Speed Door and Spiral High-Speed Door are very suitable choices.

If you need higher security and impact resistance, such as in high-risk workshops and hazardous goods warehouses, choose Steel High-Speed Door or Machine Protection High-Speed Door.

For temperature-controlled environments, such as cold chain logistics, food processing plants, you need to choose Insulated High Speed Door, they can effectively reduce temperature loss and improve energy efficiency.

For cleanrooms and other environments that require strict contamination control, Clean Room High-Speed Doors provide excellent sealing and contamination resistance to help maintain a highly clean working environment.

When making your selection, ensure that the door’s opening and closing speeds, materials, and features match your actual needs. By choosing the most appropriate high-speed door, you will be able to increase efficiency, reduce energy consumption, and optimize production processes while maintaining safety.

FAQ: Frequently asked questions about types of high-speed doors

1. What is the main difference between high-speed doors and ordinary industrial doors?

High-speed doors open and close faster and are suitable for frequent entry and exit and high-traffic places, while ordinary industrial doors usually open and close slower and are suitable for low-frequency use places. High-speed doors also provide better sealing and energy savings.

2. How to choose the most suitable high-speed door?

When choosing, you need to consider the frequency of opening and closing, the material of the door body, the functional requirements, and the installation location. For example, cleanroom environments require doors with high sealing performance, while external environments require stronger wind and water resistance.

3. What industries are fast doors suitable for?

They are suitable for warehousing and logistics, food processing, pharmaceuticals, electronics manufacturing, retail stores, and other industrial environments that require fast access and high security.

4. How to maintain the fast door?

Rapid doors require regular inspection of the door body, drive system, seals, and sensing equipment. Regular cleaning, lubrication, and inspection of the motor prolong service life and minimize breakdowns.

5. What is the service life of a fast door?

The service life of all types of high-quality high speed doors is usually 5 to 10 years, but the exact life depends on the frequency of use, environmental conditions, and regular maintenance.

Summary of different types of high speed doors

Depending on the application, speed doors are widely used in a variety of industrial environments. When choosing the right speed door, you need to consider the door’s opening and closing methods, materials, functional requirements, and installation location to ensure that it meets your work needs and optimizes operational efficiency.

Whether it’s a high-speed roll-up door, high-speed spiral door, stacking door, equipment guard door, or insulated door, choosing the right door body will help improve efficiency, reduce energy consumption, and ensure safety. By understanding the features and application scenarios of each type, you can make the best choice of door for your organization, ensuring smooth production and operation processes.

Related Articles

High Speed Vinyl Door Guide: How To Choose The Right Door Solution

Roll Up Plastic Door: Advantages, Applications And Selection Points