In modern logistics and warehousing management, the sealing performance of the unloading platform is crucial. Good sealing performance can not only effectively save energy, but also improve logistics efficiency and protect cargo safety. Inflatable dock shelters and loading dock seals are two common sealing devices. This article will help you better understand their differences by introducing their definitions, advantages, and application scenarios.

What is an inflatable dock shelter?

Inflatable dock shelter is a sealing device filled with air. As the truck approaches the unloading platform, the seal inflates and tightly wraps the truck to form an effective seal. This equipment is widely used in places that require efficient sealing and insulation.

Technical Parameters:

·Material: high-strength PVC fabric, wear-resistant and tear-resistant

·Tight sealing: Inflatable structure, suitable for various sizes of carriages

·Weather resistance: adaptable to various climate conditions, waterproof and windproof

·Installation: Usually installed on the upper and both sides of the unloading platform, automatic sealing is achieved through the inflatable device

What is a loading dock seal?

Loading dock seals are a fixed sealing device made of materials such as foam or rubber. It is installed around the unloading platform and compresses to form a seal when the truck reverses close to the platform. This kind of equipment is often used in places where sealing requirements are not high.

Technical Parameters:

·Material: high-density foam, covered with wear-resistant PVC or rubber

·Structure: Fixed design, suitable for carriages of specific sizes

·Installation: simple and fast, low maintenance cost

·Durability: able to withstand repeated impacts and crushing from trucks

Why Choose Inflatable Dock Shelter?

Excellent sealing performance: The inflatable seal can completely wrap the carriage, providing excellent sealing effect, effectively preventing the entry of outside air, dust and insects, and keeping the internal environment of the warehouse clean and constant temperature.

Example: In the food and pharmaceutical industries, where temperature and cleanliness requirements are high, the application of inflatable seals can greatly reduce energy consumption and environmental pollution.

Strong adaptability: Inflatable seals can adapt to trucks of various sizes, are not limited by the size and shape of the compartment, and are suitable for various unloading needs.

Example: Logistics centers and large distribution centers use inflatable seals to improve loading and unloading efficiency and reduce truck waiting time.

Energy saving and environmental protection: Due to its excellent sealing performance. It can significantly reduce energy consumption, reduce the burden on air conditioning and heating systems, and achieve energy saving and environmental protection effects.

Example: Cold chain logistics warehouses use inflatable seals to keep the temperature of the cold storage stable and reduce energy consumption.

Long service life: The inflatable seal is made of high-strength material. Which is wear-resistant and has a long service life, reducing the frequency of replacement and maintenance.

Example: Inflatable seals made of high-strength PVC fabric still perform well under frequent use and have low maintenance costs.

Why choose loading dock sealing?

Simple structure: The sealing structure of the loading and unloading platform is relatively simple, easy to install and maintain, and low in cost. It is suitable for small and medium-sized warehouses and places with low sealing requirements.

Example: Small and medium-sized enterprises and warehouses, due to budget constraints, choosing loading platform sealing can effectively reduce the initial investment cost.

Strong durability: Made of high-strength foam or rubber material, it can withstand repeated impacts and extrusions from trucks and has good durability.

Example: In machinery manufacturing and parts warehouses, loading and unloading platform seals can cope with high-frequency loading and unloading operations and maintain a long service life.

Economical and practical: For companies with limited budgets, loading dock seals are an economical and practical option that can provide a basic sealing effect and prevent rain and dust from entering the warehouse.

Example: In general logistics warehouses and daily consumer goods warehouses, loading and unloading platform seals can meet basic sealing needs and ensure a clean and tidy warehouse environment.

How to choose suitable loading dock equipment?

Assess needs: You first need to evaluate the type of sealing equipment based on the specific needs of the warehouse. If the warehouse has high requirements for temperature and cleanliness, it is recommended to choose an inflatable unloading platform seal. If the sealing requirements are relatively low, you can choose a loading platform seal.

Example: High-tech product warehouses have strict temperature and humidity controls and are suitable for using inflatable seals. While ordinary material warehouses can choose loading and unloading platform seals.

Consider the budget: although inflatable seals have superior performance, they are more expensive. Loading and unloading platform seals are less expensive, but their performance is relatively weak. Enterprises should make reasonable choices based on their budget.

Example: Large enterprises and high-value-added product warehouses with sufficient budgets are suitable for investing in inflatable seals. Small and medium-sized enterprises with limited budgets can choose economical and practical loading platform seals.

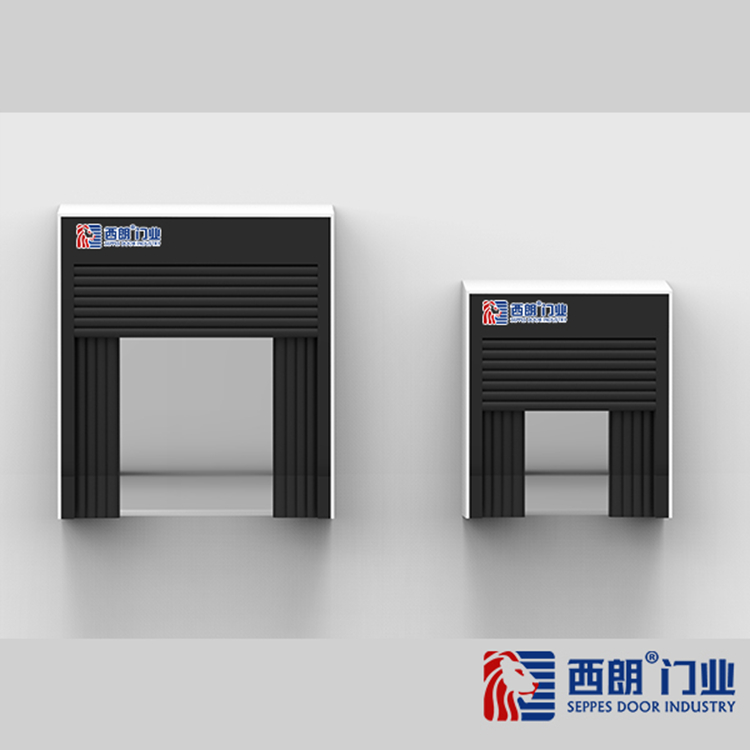

Choose a professional brand: Choosing a brand with good reputation and technical strength. Such as SEPPES, can ensure product quality and after-sales service and reduce usage risks.

Example: The high-quality unloading platform sealing equipment provided by SEPPES enjoys a good reputation in the global market. And its perfect after-sales service ensures worry-free use for enterprises.

Conclusion: Inflatable dock shelter and loading dock seals each have their advantages and disadvantages, and are suitable for different application scenarios. By understanding their differences. Companies can choose the most suitable sealing equipment according to their own needs and budget. Improving the operational efficiency and environmental quality of the warehouse. As a professional loading dock equipment supplier. SEPPES provides high-quality dock shelters and dock levelers to meet the needs of various enterprises. Whether it is the food and pharmaceutical industry that requires efficient sealing, or small and medium-sized enterprises that are sensitive to cost control. SEPPES can provide the best solutions to help companies achieve efficient, energy-saving, and safe warehousing management.

FAQ: Inflatable Dock Shelters vs. Loading Dock Seals

1. Key Differences?

✔️ Inflatable Shelter: Air-tight seal, fits all truck types, ideal for cold chain/pharma.

✔️ Dock Seal: Cost-effective, suits general warehouses, standard trucks only.

2. Which saves more energy?

Inflatable shelters cut energy use by 30% via superior thermal sealing.

3. Installation time?

Inflatable: 1–2 days (requires power) | Dock Seal: 4–6 hours.

4. Maintenance cost?

Inflatable: ~$1,000/year | Dock Seal: $300–$500/year.

5. Lifespan?

- Inflatable: 8–10 years (triple-layer PVC).

- Dock Seal: 5–7 years (high-density foam).

6. ROI period?

Inflatable: 8–14 months | Dock Seal: 3–6 months.

7. Extreme weather performance?

Inflatable: Works at -40°C to +70°C | Dock Seal: Weatherproof but degrades in large temperature swings.

8. How to choose?

✅ Inflatable: High daily throughput (>50 trucks/day), strict temp control (±2°C), high-value goods.

✅ Dock Seal: Budget limits, general cargo, standardized trucks.

9. Customization?

✔️ SEPPES offers: Non-standard sizes, hybrid solutions, smart climate control.