The pharmaceutical industry places high demands on environmental control, hygiene and safety, and efficient logistics. High Speed Doors play a vital role in the production, storage and transportation processes of pharmaceutical plants. The purpose of this paper is to discuss the value of high speed doors in the pharmaceutical industry, technical requirements, selection criteria, and to analyze their market demand and future development trends in pharmaceutical facilities around the world.

The unique needs of the pharmaceutical industry environment

The pharmaceutical industry’s manufacturing environment requires strict controls to ensure the purity, safety, and quality of medicines. Specifically, pharmaceutical environments have unique needs in the following areas:

Cleanliness: To prevent the intrusion of external contaminants, pharmaceutical plants require high levels of cleanliness and must often meet sterile environment standards.

Temperature and humidity control: Pharmaceutical processes have precise requirements for temperature and humidity to ensure the stability and efficacy of the drug product, especially during the storage and production phases.

Differential Air Pressure Control: In order to avoid air backflow and cross contamination, differential air pressure usually needs to be maintained in different areas within a pharmaceutical plant.

High Frequency Opening and Closing Requirements: Due to the high frequency of pharmaceutical production and logistics, doors that open and close quickly can increase efficiency while ensuring an airtight environment.

Compliance: Facilities in the pharmaceutical industry must meet stringent industry regulations and standards (e.g. GMP, FDA, etc.) to ensure safe and compliant drug production.

The use of high-efficiency doors can help pharmaceutical manufacturers meet these unique needs while improving operational efficiency and ensuring product quality.

Key Features of the High Speed DoorS for the Pharmaceutical Industry

Highly airtight

The pharmaceutical industry demands a dust-free, sterile environment, and High Speed Doors provide excellent sealing to prevent contaminants from entering the production area. They are designed to fit tightly into the door frame each time the door is closed. Maintaining the cleanliness of the internal environment and ensuring the purity of pharmaceutical production.

Fast opening and closing

Pharmaceutical plants often require frequent logistical operations. High Speed Doors significantly reduce air exchange due to long door opening times with opening and closing speeds of 0.8-2.0 meters per second. This fast operation improves logistics efficiency and effectively maintains a stable environment in the cleanroom.

Self-healing function

Since damage to the door body is unavoidable with frequent use, types such as High Speed Zipper Doors have a self-healing function that automatically resets the door after an impact. Reducing the need for maintenance and downtime, making them ideal for high-frequency use in cleanrooms and packaging areas.

Temperature and Humidity Control

Insulated High Speed Doors are particularly well suited for applications where efficient door insulation helps to maintain the proper temperature and humidity environment in the pharmaceutical plant, especially in refrigerated storage areas, where efficient insulation reduces energy consumption and ensures the stability of the drug product.

Chemical and corrosion resistance

In the pharmaceutical industry, where cleaning and sanitizing are frequent. High Speed Doors are constructed of high-strength materials that are resistant to corrosion, acids and alkalis, as well as cleaning agents and sanitizers, ensuring long-lasting durability for use in rigorous sanitary environments.

Intelligent Control

High Speed Doors are equipped with an intelligent control system that provides remote monitoring, automatic diagnostics and alarms to ensure optimal performance throughout the pharmaceutical manufacturing process. In addition, intelligent controls allow on-demand operation to optimize cleanroom air quality and temperature control.

These key features make High Speed Doors indispensable to the pharmaceutical industry to increase productivity and ensure product safety.

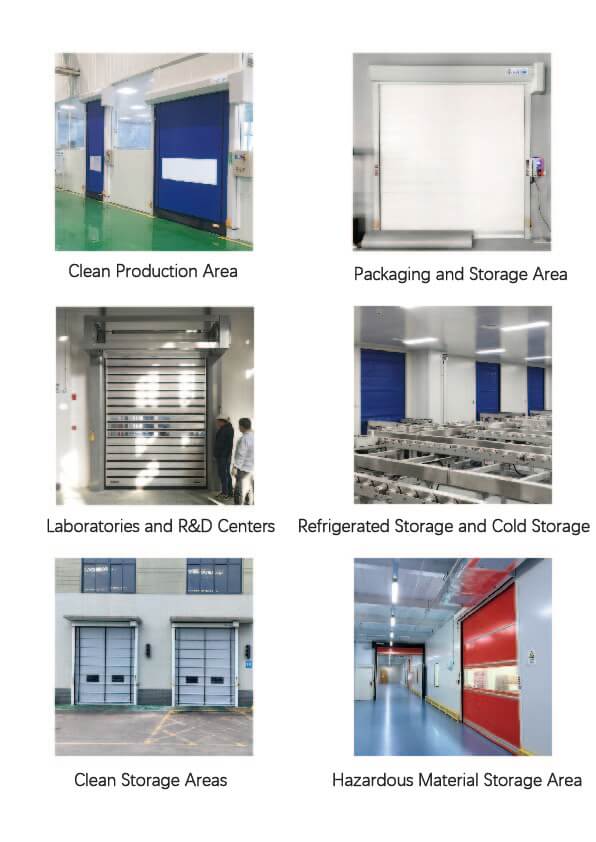

High Speed Doors specific application scenarios in the pharmaceutical industry

Clean Production Area

High Speed Zipper Doors excel in pharmaceutical production areas where cleanliness is a top priority. High Speed Zipper Doors have excellent sealing and self-repairing capabilities that allow them to quickly return to an optimal sealing state, preventing outside air or contaminants from entering the clean area. In addition, the high speed opening and closing of the doors helps to maintain the air balance inside, meeting the aseptic environment required for pharmaceutical production.

Packaging and Storage Area

High Speed Roll Up Doors are widely used in pharmaceutical packaging areas where frequent access is required for fast transportation and efficient logistical operations. Their fast opening and closing significantly reduces waiting times and speeds up the packaging and transportation process. For storage areas, especially for refrigerated pharmaceuticals, Insulated High Speed Doors maintain a stable low-temperature environment through excellent insulation, preventing temperature fluctuations from affecting the quality of pharmaceuticals.

Laboratories and R&D Centers

High Speed Spiral Doors offer superior sealing and high-performance materials for R&D and laboratory areas where temperature. Humidity and cleanliness are critical and where precisely controlled environments are required. Intelligent control features allow on-demand operation to maintain optimal temperature and humidity conditions, providing researchers with a stable laboratory environment.

Clean Storage Areas

High Speed Stacking Doors are ideal for the frequent loading and unloading of pharmaceuticals. Especially in clean storage areas, where air quality and sealing are critical, as they are designed to provide efficient sealing in environments that require large openings. The stacking design also saves space while maintaining cleanliness.

Refrigerated Storage and Cold Storage

Many pharmaceuticals need to be stored at low temperatures to ensure the stability and activity of their ingredients, and Insulated High Speed Doors excel in cold storage applications, significantly reducing energy consumption and maintaining constant temperatures inside the cold room through efficient insulation and stable temperature control. The rapid opening and closing design of these doors also prevents temperature loss, helping to save on refrigeration costs.

Hazardous Material Storage Area

Pharmaceutical plants may need to store hazardous materials such as chemicals. Reagent samples and other hazardous materials, which require a higher level of safety. High Speed Roller Shutter Doors provide additional features such as impact resistance and fire protection, creating a strong barrier in hazardous material storage areas to prevent accidental spills or fires.

These specific application scenarios demonstrate the versatility of High Speed Doors in the pharmaceutical industry and their efficiency and safety.

Key Factors in Choosing a Clean Room High Speed Door

Airtightness

Clean room environments require extremely high air quality, so sealing is the primary consideration when choosing a clean room high speed door. The door body should have a good sealing structure to effectively block the entry of outside air. Dust and microorganisms into the clean room, so as to guarantee the sterility of the internal environment and constant air quality.

Fast opening and closing speed

High opening and closing speeds can reduce air flow when the cleanroom door is open and prevent contaminants from entering. Selecting a clean room high speed door with an opening and closing speed of 1.5-2.0 meters per second significantly reduces opening time and ensures maximum protection of the air environment inside the clean room.

Self-healing function

High speed doors are frequently used in clean rooms and are susceptible to impact and wear and tear. The high speed zipper door with self-healing function can automatically reset itself after impact, reducing the damage to the clean environment and maintenance time caused by door damage, ensuring the continuous operation of the clean room.

Chemical Resistance

The cleaning and disinfection frequency in the clean room is high. The door body material should be able to resist the corrosion of chemical agents and adapt to the long-term use of disinfectants and antibacterial agents. Usually choose PVC material with chemical resistance and high durability or stainless steel made of door body to ensure the long term use of the product and the sterility of the environment.

Temperature and Humidity Control

In some cleanrooms, temperature and humidity control is particularly critical. For places where temperature and humidity need to be strictly controlled. Choosing an insulated high speed door with thermal and humidity insulation properties will help maintain constant temperature and humidity in the cleanroom and improve the quality and stability of medicines or products.

Intelligent control and alarm system

The intelligent control function of clean room high speed doors can manage the opening and closing frequency more efficiently. Through the remote monitoring, on-demand operation and real-time alarm function of the intelligent system. It can effectively prevent unintentional opening and imbalance of the pressure in the clean room. In addition, alarms in the event of a malfunction help minimize the impact on the clean environment.

Compliance with industry standards

In pharmaceutical and other industries with stringent hygiene requirements. Doors need to comply with GMP, ISO, FDA and other relevant industry standards to ensure that they meet cleanroom application specifications and certification requirements. Choose a Clean Room High Speed Door that meets standards for production safety and product compliance.

In cleanrooms, the high sealing, fast response and intelligent management functions of clean room high speed door can ensure the cleanliness and stability of the production environment. Which is the key to safeguard the operational efficiency and safety of cleanrooms in pharmaceutical, food, electronics and other industries.

Technical parameters and standard requirements

When selecting a clean room high speed door. The following technical parameters and standards are key elements to ensure its efficient and safe application in the clean room:

Opening and closing speed

Standard range: 1.5-2.0 meters/second.

Rapid opening and closing reduces the time it takes to open the door and reduces the risk of contamination from air circulation. Making it suitable for clean environments with frequent operations.

Sealing Rating

Standard rating: IP65 or higher.

Ensure efficient isolation of dust and microorganisms by the door body. Conform to the sealing requirements of the cleanroom, and safeguard the air quality and environmental control of the cleanroom.

Wind Pressure Resistance

Standard range: 400-600Pa.

Suitable for clean environments that require air pressure difference. Preventing the door body from being affected by pressure changes and safeguarding the air balance in the clean room.

Temperature and Humidity Adaptation Range

Applicable temperature: -30°C to +50°C.

Humidity tolerance: 90% relative humidity or less.

In pharmaceutical, laboratory and cold storage environments. The door body should be able to maintain stable performance under constant temperature and humidity fluctuations.

Material Selection

Recommended materials: high-strength PVC, stainless steel or aluminum alloy.

Select corrosion-resistant, chemical agent-resistant materials to ensure that the door body can withstand frequent cleaning and disinfection in the clean room. In line with the requirements of long-term use.

Self-repair function

Self-repairing design ensures that the door curtain can be quickly reset after being impacted under high-frequency use in the cleanroom. Which reduces maintenance needs and production interruption.

Intelligent control and alarm system

Control system: PLC control, remote monitoring and alarm function.

Intelligent control system can accurately manage the opening and closing frequency. And the automatic alarm system prompts the maintenance demand in case of abnormality, ensuring the continuous stability of the clean environment.

Compliance with industry standards

GMP (Good Manufacturing Practice): For the pharmaceutical and food industries, ensuring that products meet the requirements of the production environment.

ISO14644-1: international standard for cleanroom environments, ensuring that doors meet the requirements of specific cleanliness levels.

FDA standards: for pharmaceutical and medical environments, ensuring that products comply with health and safety standards.

These technical parameters and standards not only help to select the right clean room high speed door, but also ensure that it can operate stably for a long period of time in the clean room, meet the strict industry specifications. And guarantee the sterility of the environment and the quality and safety of the products.

High speed doors application cases in Pharmaceutical Industry

In a large pharmaceutical plant in Europe and the United States. SEPPES’ High Speed Zipper Doors are used to achieve fast and safe isolation between the cleanroom and the production area, which meets the GMP requirements for a sterile environment. The application of High Speed Doors in this pharmaceutical plant enables effective control of air circulation in the workshop. Saves the cost of refrigeration and maintenance of the clean environment, and improves the overall production efficiency.

High Speed Door Market Outlook and Technology Development

Market Outlook

With the acceleration of global industrialization, the demand for High Speed Doors in a number of industries continues to grow. Whether in the pharmaceutical, electronics, food processing, or logistics and warehousing fields, high-speed doors are increasingly valued for their dual advantages of efficiency improvement and environmental protection. Especially in industries with strict environmental controls. Such as cleanrooms and cold chain logistics, the application demand for High Speed Doors will continue to expand. Asia Pacific and European markets are expected to be the fastest growing regions in the coming years due to their increased industrial scale and production safety requirements.

Driven by Intelligent and Automation Technologies

The future growth of High Speed Door is focused on intelligence and automation. With the rapid advancement in Internet of Things (IoT), Artificial Intelligence (AI), and sensing technologies. High speed doors are becoming automated, remotely managed, and monitored in real-time. Intelligent systems are capable of automatically adjusting the frequency and speed of door opening according to traffic intensity and security needs. Significantly improving production and logistics efficiency. At the same time, the remote control function also makes the management more convenient, applicable to the intelligent management of modern industrial sites.

Enhancement of energy efficiency and environmental protection needs

With the strengthening of environmental protection policies and the concern of enterprises for sustainable development. The technical improvement of high-speed doors in terms of energy saving and environmental protection has become a new trend. Future High Speed Doors will pay more attention to energy efficiency. And further improve the insulation and sealing performance to reduce energy consumption. Insulated high speed doors with excellent thermal insulation performance will become an important product type in the market due to their great demand in the frozen and refrigerated industry. The use of new materials and structures will enable high speed doors to adapt to more complex temperature and humidity environments while improving energy efficiency.

Selection Guide and Brand Recommendations

Selection guide:

Define the needs: choose the appropriate door body according to the specific needs of the pharmaceutical scene.

Match the technical parameters: Make sure that the door body you choose meets your needs in terms of speed. Sealing and other parameters.

Recommended brands: Hörmann, ASSA ABLOY and SEPPES are among the well-known brands that offer high-efficiency doors that meet pharmaceutical industry standards.

FAQ

What types of high speed doors are suitable for cleanrooms?

High Speed Zipper Doors are the best choice for cleanrooms with high sealing and self-healing capabilities.

How do I choose a zipper door for a cold storage area?

Insulated High Speed Doors are recommended for cold storage areas, offering high thermal performance and adaptability to extreme temperatures.

How can I ensure GMP and FDA compliance for my pharmaceutical industry?

Ensure that you choose a product that complies with CE and GMP approvals. While meeting the technical requirements of high sealing and chemical resistance.