In today’s industrial and commercial buildings, construction quality and efficiency are vital pillars of success. The construction of modern facilities often incorporates reliable high-speed fabric doors to save energy and optimize workflow. What truly sets these systems apart is the variety of High-Speed Door Materials available, allowing for specialized performance in diverse environments.

For this reason, this post will analyze the different High-Speed Door Materials used in modern manufacturing. We will evaluate the performance, sustainability, and versatility of these materials to provide the answers you need regarding durability, insulation, and environmental impact. This comprehensive guide on High-Speed Door Materials will help you make an informed decision for your next project.

Introduction

Your industry and commerce facilities would be inefficient and non-functioning without high-speed doors. Doors are made of different materials, and each of these materials will determine how adaptable and durable they will be. Innovations these past years introduced PVC fabrics, aluminum, advanced composites, and reinforced steel, which all contribute to improving doors and their ability to withstand corrosion, harsh weather, and wear and tear. Innovations in sustainability became new trending materials. These materials are recyclable and energy-saving. The new high-speed doors will be energy-saving, environmentally friendly, and will have materials providing long-lasting reliability.

Importance of High-Speed Doors in Modern Industry

Rapid doors save time, costs, and increase safety in modern automation. They are engineered to create seamless workflows in the operation. Their high speed increases the rate of turnover. They are deployed in automation, food, pharma, and logistics industries to keep their environments at a temperature and cleanliness.

Recent adaptations like fully integrated smart systems, automation, and ergonomics help keep energy costs low and the enviroment low to no air exchange. The durable construction helps provide the absence of downtime even in the busiest and most extreme conditions. The safety systems, even at high load conditions, are low to no risk.

Investing in the latest technologies helps achieve economic and efficiency gains for the industry. Closing the air preheats also helps achieve energy savings to achieve modern goals. The doors ensure modern features like reliability, flexibility, and safety.

Impact of High-Speed Door Material Selection on Performance

The construction of high-speed doors lets us understand their purposes.Facility managers select different materials like PVC, aluminum, and steel to match specific operational requirements. PVC excels in scenarios requiring rapid and high-frequency cycles. In contrast, the food and processing industries prioritize stainless steel for its superior corrosion resistance and compliance with strict hygiene standards.

The quality of insoles that high-speed doors offer is easily recognized. Ensuring a facility is efficient in energy drainage is a must, especially in cold del involved facilities. The materials involved in constructing the workshop doors will also alter the noise levels of the work environment. In the industry, the selection of a wide range of materials, such as self-repairing fabric and reinforced polymers, increases the lifespan of the doors. The right choice of materials contributes to the efficiency, safety, and sustainability in the use of polymer fast cycles in the industrial environment.

What Are High-Speed Doors?

Definition and Core Characteristics

High-speed doors are industrial doors that operate at a quicker speed compared to traditional doors. They are great at ensuring efficiency, safety, and reliability in different types of applications, including residential settings. Warehouses, cold storage, and manufacturing plants are examples of places that need rapid opening and closing of their doors.

Key Characteristics of High-Speed Doors

Operational Speed

Depending on the model, high-speed doors can open and close anywhere between 30 inches and 100 inches per second. This movement minimizes downtime and optimizes workflow in busy places.

Additional Safety Features

These doors come with motion sensors, safety light grilles, and automated reversing systems, lowering the risk of major incidents and protecting your personnel and valuable equipment.

Long Last Construction

These doors can stand the test of time. They are built with high-quality materials such as reinforced PVC, steel, and aluminum. They can endure extreme wear and tear even in high-pressure environments.

Energy Conserving

By creating an impenetrable barrier to outside air, this door helps keep your facility’s internal temperature regulated. This is especially helpful in cold storage or climate-controlled locations. This creates stable energy savings.

Quieter Levels

Modern high-speed doors are designed to be as loud as possible, and even incorporate noise-reducing materials. This can be very helpful in environments where noise is an issue.

These doors provide long-term, reliable, and superior performance.

Main Applications by Industry

Due to features like time-saving, flexibility, and durability, high-speed doors are paramount in various industries. Mentioned below are five industries that rely on high-speed doors:

Food and Beverages

In the food and beverage industry, high-speed doors help in controlling hygiene, minimizing contamination, and regulating temperature in cold storage areas. Moreover, they help in the improvement of the operational flow in food processing facilities.

Pharmaceutical and Healthcare

In the healthcare and pharmaceutical industries, high-speed doors are used to help maintain regulatory standards. They help in cleanroom protection and the protection of sensitive materials from contamination.

Warehousing and Logistics

In distribution centers, high-speed doors reduce the operational energy wastage as well as the congestion. They help in optimizing operations by increasing movement in and out of the distribution center. Therefore, they are vital during busy loading and unloading operations.

Automotive and Manufacturing

In automotive and rugged manufacturing industries, high-speed doors are used to help reduce dust and noise. Additionally, they help in the improvement of workflow and the reduction of downtime during the operation of the production line.

Retail and Commercial Facilities

In commercial retail facilities like shopping centers, high-speed doors are used to enhance operational efficiency. Energy optimization and improved traffic flow are other effects of high-speed doors.

Every one of these industries gains major advantages from high-speed doors due to their bespoke features and the long-term cost savings.

Primary Types of High-Speed Door Materials

PVC Fabric

PVC fabric is one of the most preferred and most flexible materials for high-speed doors. PVC is inexpensive and is made to endure heavy use. Fabric is good for all types of environments and is extremely resistant to wear and tear. That’s what makes PVC the best choice for all commercial and industrial applications. PVC has good resistance to moisture, chemicals, and even UV rays, ensuring that it lasts for a long time.

Because of the lightweight nature of the PVC fabric, the high-speed doors operate faster. This is a very important aspect of workflow efficiency when doors are in high-traffic areas. The flexible design of the PVC fabric allows for a large number of customization options, including transparent panels, which improve visibility, and reinforced structures for more security. Newer technology PVC fabric high-speed doors now offer better insulation. That improves energy savings and better climate control. With all of these benefits, PVC fabric is the best choice for high-speed doors.

Aluminum and Steel

The high-speed door systems industry utilizes aluminum and steel due to their strong nature. Aluminum doors are strong yet lightweight. They resist corrosion and are great for climates with high moisture or chemicals. They are low-maintenance.

Manufacturers often apply specialized coatings to aluminum doors to enhance their aesthetic appeal. In contrast, steel doors provide immense strength and resistance to damage, making them the ideal choice for heavy industrial, high-volume use, or high-security zones. Because these doors feature advanced protective coatings, they last a long time without succumbing to rust or wear.Modern engineering utilizes these High-Speed Door Materials and advanced techniques to create high-speed doors that meet the specific needs of various businesses and industries.

Composite and Engineered Materials

Increasingly, industrial high-speed doors are made using composites and engineered materials. A great example would be Composite materials like fiberglass reinforced paneling. It is light, durable, and corrosion-resistant, making it ideal for overhead door™ applications. It also withstands chemical exposure and temperature variation, making it great for industrial and manufacturing facilities that have strict cleanliness requirements, like food processing and pharmaceuticals.

The performance of high-speed doors is further enhanced with engineered materials like advanced polymers and hybrid metal. Polymers have a metal-like rigidity and provide great thermal insulation and flexibility to smooth operations under extreme temperatures. Hybrid alloys combine metals from different engineered materials to improve wear and energy efficiency. This means modern high-speed doors can be configured to meet everyone’s needs with fast operation and reliability. Also, they require very low maintenance for a variety of industrial and commercial applications.

Material Trends for 2026 and Beyond

Sustainable/Eco-Friendly Materials

In the case of high-speed doors, the most recent innovations in materials have been influenced by the need to promote high performance and sustainability. An example of this is the use of recycled and recyclable materials to make doors. For example, aluminum frames that contain recycled materials can be used to limit the consumption of raw materials while keeping the aluminum frames structurally sound. In addition, instead of using old, oil-based plastics, doors can now have components made from bioplastics which come from renewables like corn and sugarcane.

Manufacturers can use composites that have structural strength and environmentally friendly reinforced natural fibers like bamboo or jute. Along with materials, the use of synthetic bioplastics is predicted to be environmentally friendly and to lower the eco-impact of the final doors. Overall, these innovations of high-speed eco doors will be sure to economically benefit consumers while protecting the ecosystem.

Enhanced Durability Innovations

Durability of high-speed doors has greatly improved due to new developments in design and materials. Today’s high-speed doors are engineered to endure harsh environmental conditions. This includes heavy winds, temperature fluctuations, and high usage. New materials, such as reinforced fabric with stainless steel and aluminum with corrosion-resistant properties, are used to increase longevity.

Manufacturers are also using newer sealing technologies, which provide better insulation. This protects against wear and tear to the doors over time while increasing energy efficiency. Another important innovation in the industry is self-repairing technological features. Self-repairing curtain doors can reset automatically after being struck, reducing system downtime and cutting repair costs. These technologies integrate with smart sensors and IoT systems, providing high-speed doors with cutting-edge reliability and performance. This also allows the doors to be used in a wider range of demanding environments.

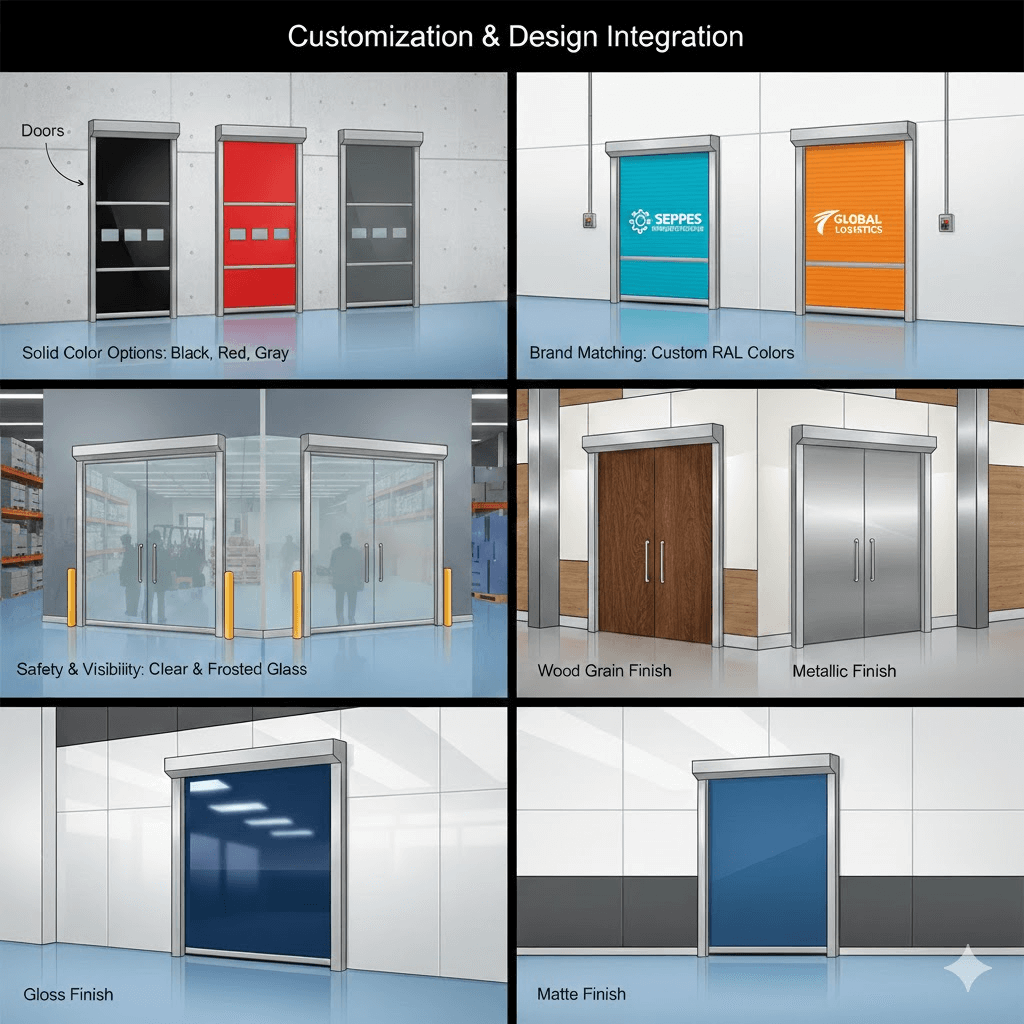

Customization and Design Integration

Requests for Color and Finish Options

High-speed doors are extremely efficient and customizable, catering to the functional and aesthetic demands of various commercial and industrial spaces. Below are some outlines of customer requests regarding finishes and paint colors.

Solid Color Doors

High-speed doors are frequently selected in the solid colors of black, white, red, gray, and blue. These colors are suitable for any work environment and present a clean, professional image.

RAL Doors

Facilities aiming for brand recognition through visual uniformity and consistent representation of the company often solicit doors in RAL. These doors are tailored to the company’s unique color specifications.

Glass Doors

To provide safety and visibility, some customers have requests for glass doors that are clear or frosted, ensuring a safe view of the other side of the door, especially when installed in high-traffic areas.

Textured Finishes

Commercial spaces desiring a decorative or premium look often select doors with a finish that appears wood or metallic.

Matte and Gloss Finishes

Clients specify finishes on high-speed doors like gloss or matte to match with other elements of the space, balancing out the design.

Facilities can combine visual function and performance with high-speed doors tailored to specifications. These doors can fit the design and functional needs of any space.

Alignment with Architectural Needs

Construction rapidly changes, and so do customer needs and expectations.Manufacturers frequently customize durable and functional high-speed doors to meet specific architectural requirements. These systems integrate seamlessly into almost any design, utilizing cutting-edge absorbent materials and modern engineering techniques. Custom-fit installations maximize space even in critically designed and engineered areas, ensuring the door complements the building’s footprint perfectly. High-speed doors also come with added insulation and other features that will fit a design to meet the needs of a highly energy-efficient space, or areas that may require sound design to be ideal. This level of versatility helps to modify the design expectations of any space more quickly.

Material Selection by Door Type

Material Selection for Rolling Doors

Durability and functionality are two very important factors to consider when choosing materials for rolling doors. Some materials that are commonly used to construct rolling doors include Aluminum, steel, and some more expensive options such as galvanized steel. Among these options, galvanized steel is one of the best as it is very strong and highly resistant to corrosion, making it ideal for most industrial and commercial applications.Aluminum offers a lightweight, rust-resistant option, making it an excellent choice for high-frequency rolling door installations. This material performs exceptionally well in temperate regions and environments with high moisture exposure. For tougher conditions, stainless steel stands out as the premier material, especially in areas requiring high hygiene standards like food processing facilities.

Modern rolling doors are also fitted with extra coatings, such as a powder finish, to enhance aesthetics and to give the doors added value through weather protection. Some rolling doors have added insulation to help with energy efficiency and temperature regulation, which also aids with noise control.

To give rolling doors the best performance possible and to last a long time, choosing the best materials to meet the specific needs of the environment is very important. These materials can be used for field industrial rolling doors, retail rolling doors, or rolling doors for almost any other application.

Material Selection for Folding, Sliding, and Swinging Doors

How well folding, sliding, and swinging doors work and how long they last are partly determined by the materials used to make them, including how the materials look. Each kind of door requires its own unique materials and design considerations based on its own purpose and the conditions of its installation environment. Aluminum’s light weight and high corrosion resistance make it a popular choice for sliding doors, allowing for versatile use in both indoor and outdoor applications. Similarly, designers frequently pair tempered glass with aluminum frames to achieve a modern aesthetic, leveraging the metal’s low weight and natural durability.

Quality timber or composite wood significantly enhances folding doors. These materials provide an elegant aesthetic and allow for ornate or patterned designs while delivering superior insulation and sound resistance. For residential swinging doors, builders often select steel-reinforced or insulated PVC due to its high energy efficiency, minimal maintenance requirements, and low construction costs.

Incorporating thermally broken frames improves energy retention and temp regulation on all door types. Rust-resistant coatings make doors built for humid and coastal areas last longer. Weighing factors such as longevity and efficiency helps mfg and consumers choose the right materials for folding, sliding, and swinging doors.

Impact of Materials on Performance and Compliance

Insulation and Energy Efficiency

Innovative materials contribute immensely to insulation and energy efficiency when it comes to the construction of high-speed doors of today. High-speed doors are designed with materials that provide energy efficiency and insulation. Doors made of double-layered PVC, Thermal insulation core systems, or Polyurethane foam filled panels help to minimize energy consumption by reducing heat transfer and maintaining indoor temperatures. Moreover, the seals around the doors minimize energy loss by preventing the leakage of air.

As per the latest industry research, high-speed doors are beginning to use the latest innovations to achieve the best thermally insulated performance. Doors fitted with industrial insulated slats, thermal break systems, and high-performance materials allow the user to greatly improve the energy compliance and the U-values of the doors. These technological innovations not only achieve the best in the industry heating and cooling cost savings, but best in the industry SBT (science-based targets) in carbon savings. By utilizing the best in industry high-performance materials, a business improves energy efficiency and operational reliability.

Fire Ratings and Regulatory Requirements

When picking high-speed doors, they should be compliant with regulatory requirements, including certain fire ratings. Whether the high-speed doors are used in an industrial or commercial setting, the doors must comply with the fire safety regulations in the region. The United States has the NFPA 80, while Europe has EN 16034. In the U.S. and Europe, the regulations address the fire-resistant materials and how they apply to limiting the spread of fire, and how fire-resistant the materials are to extreme temperatures.

The fire-rated materials undergo testing for fire integrity, insulation, and smoke. Manufacturers commonly utilize fire-retardant coated fabrics, galvanized steel, and aluminum with fireproof coatings that protect the core layers. Modern innovations also introduce fire-rated transparent panels that strictly comply with high-speed door safety standards.

With high-speed doors meeting fire safety regulations, businesses are protecting employees and important property from needless risk. Also, due to the ever-changing fire safety regulations, businesses should regularly maintain and check that the high-speed doors are certified to comply with the regulations.

Leading Manufacturers and Their Innovations

Overview of High-Speed Doors Market Leaders

There are many reliable manufacturers of high-speed doors. They have built up their reputations with high quality, innovative design, and tom technological advancements. Below are five manufacturers producing high-speed industrial doors.

Hormann Group

Hormann Group is known for its industrial high-speed doors. Their doors are reliable with energy-efficient operation. They put lots of effort into innovation with doors that have superior insulation and many advanced safety features.

ASSA ABLOY

ASSA ABLOY tailors high-speed doors to many industries, including food processing and logistics. Their high-speed doors are operationally efficient with rapid opening speeds and advanced automation.

Rite-Hite

Rite-Hite high-speed doors are for heavy-duty and high-demand industrial use. Their high-speed doors have advanced sealing systems to assist with energy savings and climate control.

Rytec Corporation

Rytec specializes in high-speed doors for extreme environments and is known for reliability and durability. They design their products for many scenarios, like cold storage, clean rooms, and heavy manufacturing.

TNR Industrial Doors

TNR specializes in extreme environment use. Equipment is made for high-speed door control in a consistent operational life. Their products have a high operational life and are made to perform optimally for long periods of time.

These manufacturers shape the industry with new standards in safety, functionality, and efficiency in the ever-growing high-speed doors market.

SEPPES High-Speed Doors

This company focuses on innovation when it comes to high-performance door solutions. SEPPES’ products are tailored for today’s industrial plant. Their doors are integrated with the latest technology to be fast, energy efficient, and durable to suit a broad spectrum of industries, including, but not limited to, logistics, manufacturing, and cleanrooms.

These manufacturers collectively set benchmarks in safety, functionality, and efficiency within the high-speed doors market, contributing to a continually evolving industry.

Recent Product Launches

Some large manufacturers in the high-speed doors sector continue to produce innovative products that optimize performance and efficiency. One such example is the ASSA ABLOY RapidRoll Clean, designed for cleanroom applications. This high-tech door is able to clean and minimize levels of contaminants in the airflow while maintaining critical industry-leading high-speed levels for the pharmaceutical and electronic sectors.

The other great release is the Hörmann TNR HDS-SR, a high-speed rubber door made for extreme endurance and harsh conditions. Thunder’s Rubber Extreme Endurance door is made and weather-resistant for the mining and waste management sectors and other heavy industry.

Rite-Hite has made even more updates to their FasTrax Doors with new options for sealing and width, all designed for maximum efficiency and energy saving.

The releases mentioned show the emphasis of the industry on engineering and precise construct while high tier modern performance.

Market Outlook: Regional and Global Perspectives

Fastest-Growing Regions and Sectors

High-speed doors can be found in the majority of the industrial sector today, including places in the logistics and warehousing sector, as well as places where industrialization and urbanization are developing technologically. The regions in the world with the most growth in demand for high-speed doors include North America and the Asia Pacific. Because of the extremely rapid growth of the manufacturing and e-commerce distribution hubs of Asia, especially in China and India, the Asia Pacific region is leading in the production and sale of high-speed doors. However, in North America, there is a strong demand coming specifically from the automobile, food and beverages, and pharmaceuticals industries. Additionally, North America has a great demand for specialized doors and energy-efficient doors due to regulatory compliance and operational requirements.

High-storage clean rooms and chemical handling industries are the primary industries driving the demand for high-speed doors. These industries require strong, insulated, and customizable doors for food that control for safe, clean storage. The doors also come with reinforced fabric, PVC, and aluminum to make the high-speed doors more effective and versatile for specific industries.

Regional Material Trends

The specifics of what types of materials will be used for high-speed doors will differ based on what that region needs internally. This includes things like overall temperatures of the area, what the regulatory requirements are, and the dominant industry. North America, for example, widely uses insulated high-speed doors in the cold storage and warehouse industries. This is due to the temperature control required and the materials used (aluminum and thermoplastics). For Europe, the focus is on sustainability and energy efficiency. There is a growing trend to use more recyclable and eco-positive materials, such as reinforced fabric that has a low environmental impact for use high speed doors.

The growing trends of materials used in doors in the Asia-Pacific region can be attributed to the cost-efficient alternatives that are materials such as PVC and lightweight steel. This region is also seeing the growing use of smart technologies, and so the materials used in high-speed doors have to be compatible with automation systems. In the Middle East, where the regions industrial needs are more complete, the focus is on the durability of the high speed doors. More sand and corrosion-resistant aluminum and reinforced polymers are used.

Thus, doors that use more environmentally viable and cost-efficient materials are needed to meet the area’s industrial needs more fully. The demand for high-speed doors is more focused on the industrial advancements of the area.

Conclusion

H3: Summary of Material Innovation Impact

Materials sciences have led to many new improvements in the design and functionality of high-speed doors. Furthermore, the innovations in design have led to specific solutions to different industrial challenges. Some of the innovations in the industry have led to the following impacts in design: enhanced customer service and efficiency.

Enhanced Door Durability

The lifespan of high-speed doors has been improved by the following materials: reinforced polymer and corrosion-resistant aluminum. These new materials have shown improved operational durability in excess of 30% when compared to more traditional materials.

Reduced Door Thermal Conductivity

The combination of new insulating fabrics and improved sealing technology has improved energy efficiency. Some high-performance insulated doors have shown a 20% reduction in annual energy costs.

Resistance to Adverse and Extreme Environmental Conditions

The use of new specialized materials, including UV-resistant coatings and anti-corrosion alloys, enables doors to withstand extreme climates, both high heat and freezing. Performance reliability has been shown to improve by as much as 40% in harsh climates.

Noise Level Innovations

Innovations that use sound-absorbing materials have improved industrial noise levels. Some of the new industrial high-speed doors have improved sound levels by 15 decibels in the facilities equipped with these doors.

Reduced Cost of Maintenance

Self-lubricating and wear-resistant materials now predict fewer maintenance cycles for facility operators. On average, high-speed doors save customers 25% in their operational lifecycle costs.

The need for innovation to tackle industrial challenges and improve performance and sustainability is highlighted by these advancements in material science.

Key Considerations for Specifiers and Facility Managers

The great thing about high-speed doors is that they assist us with the overall efficiency of the operations that happen in the building, accommodating various applications. When I consider high-speed doors, I try to achieve a balance of the things that they impact. This includes things such as the overall cost, the door’s energy efficiency, the insulation capability of the door, the overall safety of the doors, some may have safety sensors, or the doors may have the ability to breakaway, and some safety systems require a breakaway feature, or the doors may have safety features.

And I try to balance the operational efficiency that the doors will bring to us with the value that they bring. This is to make sure we also achieve our sustainable operational goals.

Frequently Asked Questions (FAQs)

What are high-speed door materials commonly used in industrial openings?

High-speed doors need to be built from very particular materials such as polyester weave materials, aluminum or galvanized reinforced steel, PVC, and high-speed rubber to ensure high performance. On the one hand, high-speed fabric doors may use polyester weave materials and reinforced steel to ensure the doors have a good seal. On the other hand, stainless steel and steel components are used in the food processing and pharmaceutical industry to ensure the doors meet food processing requirements and corrosion resistance.

How does the curtain material affect opening speed and cycle life?

The curtain material impacts how quickly a high-speed door opens and closes. PVC and polyester weave materials have few curtain materials and can maintain a door that opens and closes with high cycles. Heavier materials provide better insulation, but can slow the speed of the door. The right balanced choice of materials can provide great insulation and emphasize the safety of the high-speed door.

Are fabric door curtains suitable for doors in food and beverage facilities?

Yes, fabric high-speed doors and PVC curtains are extensively used within the food processing and beverage industry because of their hygiene-friendly surfaces, low risk of contamination, and ability to control the temperature and airflow between zones. The presence of stainless steel and washable PVC surfaces, along with sealed edges and soft bottom edges, or zipper systems, addresses hygiene requirements and protects against the ingress of pests or contaminants.

What are the advantages of high-speed rubber and soft bottom edge designs for freezers?

High-speed rubber bottom edges and soft bottom edge designs enhance the sealing performance and lessen the risk of unintentional damage during roll-up or roll-down operations. In freezers and coolers, the listed materials serve to insulate, limit condensation, and maintain uniform internal temperatures. The flexible edges enable free passage of vehicles or forklifts without damaging the curtain and provide quick reverse action on impact to protect personnel and goods while operating at peak efficiency.

How does the installation of high-speed fabric doors differ from conventional overhead doors?

The installation of high-speed fabric doors is done with a lot of attention to alignment, drive system calibration, and the installation of safety and control systems. Unlike standard overhead or garage door installations, the installation of fabric high-speed doors needs to factor in closing and opening speeds, high-cycle drive components, and proper sealing to satisfy the requirements of insulation and hygiene. Such installations can make sure that the roller, shutter guides, and perimeter seals are operating as intended and conform to the best operational and safety standards.

What safety features should be included to mitigate accidental impact and contamination?

Safety features include presence-sensing edges, reverse-on-impact, photo-eye sensors, zone speed control, and soft bottom edges. This combination helps to minimize the risk of harmful collisions. In the food and pharma industries, features that minimize the risk of contamination are crucial. These include sealed seams, stainless steel framing, and washable PVC. High-performance drive systems with managed acceleration and deceleration help to support minimal maintenance and safe daily operations.

How do high-speed roll-up doors improve efficiency and productivity in industrial environments?

High-speed doors, both roll-up and fabric, minimize air exchange, help to maintain temperature differentials in coolers and freezers, and reduce wait times for personnel and forklifts, improving productivity. Fast opening speeds and high cycle throughput reduce energy loss and improve HVAC efficiency. Reinforced, lightweight door curtains reduce drive system wear and improve uptime and maintenance in commercial doors for the manufacturing, distribution, and beverage industries.

What factors determine the best material choice for a specific industry application?

When selecting High-Speed Door Materials, facility managers must evaluate several environmental and operational factors. Key considerations include extreme temperatures, potential condensation, and the risk of corrosion. Decision-makers should determine the required opening speeds, daily cycle counts, and specific hygiene or contamination standards. Furthermore, they must assess whether the application demands high-level insulation and define the door’s primary functional role.

In food processing and pharmaceutical sectors, manufacturers typically specify stainless steel framing and PVC curtains to facilitate frequent wash-downs or utilize specialized insulated curtains to maintain climate control.

In industrial and commercial warehouses, PVC that has a polyester weave is lightweight and allows high-speed operation. Other factors include how well the drives work together, how well the doors seal, how little maintenance the doors will require, and meeting the regulatory standards for that area, whether it is North America or other countries.

Reference Sources

- High-Speed Door Assembly – UNT Digital Library

This source discusses a high-speed door assembly, including its components like actuator cylinders and piston rods.

Read more here - Blast Performance of Hollow Metal Steel Doors – VTechWorks

This paper provides a semi-empirical analytical methodology to predict the deformation response of hollow metal doors under specific conditions.

Read more here - MCU System-based Intelligent High-speed Elevator Door – Harvard ADS

This study focuses on the safety core components of high-speed elevator doors, which may provide insights into material and system design.

Read more here - SECTION 08 33 13 – Coiling Counter Doors

This document from a government portal discusses high-speed doors as a subcategory of high-performance doors, emphasizing their use in vehicular access.

Read more here - FireKing® – Overhead Door Product Brochure

This brochure provides details on advanced product design and manufacturing for high-performance doors, including high-speed options.

Read more here