For businesses looking to improve efficiency, security, and climate control, the installation of high-speed doors improves all of these features. Managing busy/clean industrial sites or warehouses? The right high-speed doors can significantly improve daily operations. This guide walks you through the process of high-speed door installation, providing professional tips and insights for a smooth setup. We’ll cover everything you need to know, from the key features to consider when selecting doors to the steps necessary for an effective installation in order to help you make the best decisions to achieve the finest results. Continue reading to learn how to maximize your space with high-speed doors.

Introduction to High Speed Doors

High-speed doors are built to open and close quickly, which makes them great for improving efficiency. They are used in many different industries, ranging from industrial and commercial to logistics sectors. In these businesses, temperature control, improved workflow, and energy savings are of primary concern. High-speed doors are built to last with durable materials and reliable mechanisms that are designed to take heavy use. This makes them cost-effective for businesses that want to optimize their facilities.

Importance of High Speed Doors in Industrial and Commercial Settings

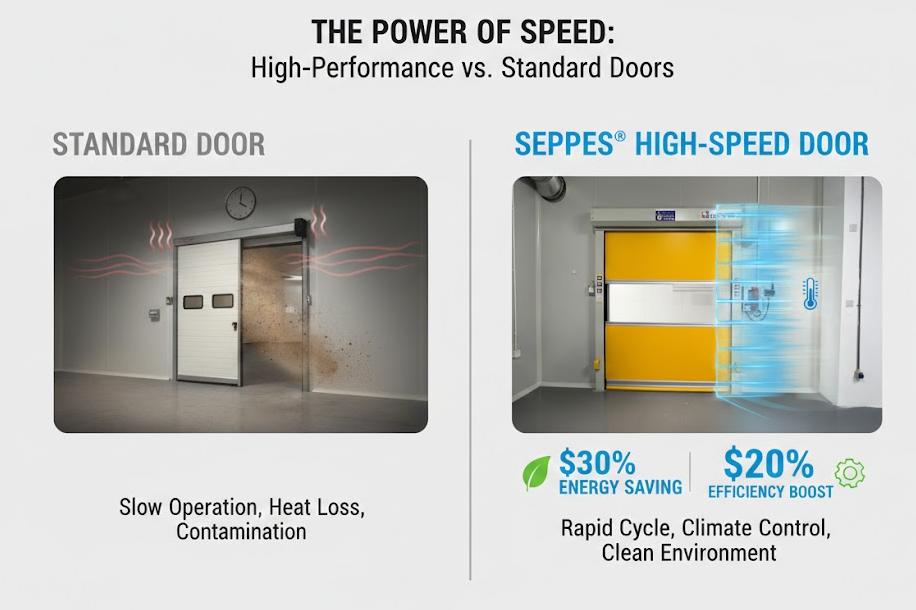

Due to the various ways they aid operational efficiency, high-speed doors are vital to almost any industrial and commercial setting. Because of their design, they are able to maximize their workflow and minimize delays by speeding up the movement of people, vehicles, and/or goods. They are also energy efficient. In areas that need to be kept cold or controlled, like refrigerated warehouses or any other temperature-sensitive zones, they are able to keep heating and cooling losses to a minimum.

High-speed doors also provide increased safety and cleanliness. Because they open and close so quickly, they can be very useful in cleanrooms and food-processing environments, as they minimize cross-contamination, and in areas with a lot of people, they can also help reduce security risks. Many of today’s high-speed doors have features like motion sensors, automated controls, and pressure-sensitive edges, which allow them to operate in more extreme or difficult environments. Because high-speed doors meet operational and sustainability goals, they are a great option for companies that wish to improve their productivity and lower their expenses.

Benefits of High Speed Door Installation

Improved Energy Efficiency

The quicker the high-speed doors close, the less air losing the barrier. With the energy-saving doors, customers will spend less money on heating and cooling. One energy study found that companies can save as much as 30% on energy bills with high-speed doors.

Enhanced Security

The quicker the doors close, the less time that people can walk in and out, and the less time that the doors are open. This increases the safety and security at the premises, as less time is available for people to walk through. Most high-speed doors have locking options for added security.

Reduced Downtime

Bottlenecks in busy environments are eliminated with high-speed doors. Keeping high traffic zones open longer increases productivity. With the installation of high-speed doors, companies report that workflow efficiency increases by 20%.

Improved Hygiene and Contamination Control

High-speed doors are especially important in the food and pharmaceutical industries. Less dust and bugs can get through, and with clean environments, industries can meet the standards of regulations.

Cost-Effective Durability

High-speed doors are designed to withstand wear and tear, require less maintenance, and last longer than standard doors. This means less repair and replacement costs, translating to savings over time, making your business a more durable and long-lasting investment.

Compliance with Modern Standards

High-speed door installations are completed to modern standards. This means they are completed to safety standards and operational safety. As far as industry standards go, these doors operate in an ISO-environment and an EN-13241-1 environment. This goes for durability, performance, and safety. Also, many installations are tailored to building codes and energy compliance standards, which means not wasting functionality.

High-speed doors used to not have sensors, and that is why the safety of the workplace has increased due to the presence of high-speed doors. In addition, the high-speed door industry has become more environmentally conscious. It is no longer a shock for a high-speed door to have compliance sensors. By having these sensors and other industry-standard devices, the doors are not in compliance. They become more efficient. Most importantly, a door with compliance sensors that is high-speed and has energy-efficient materials is environmentally conscious.

Pre-Installation Considerations

Site Assessment for High-Speed Door Installation

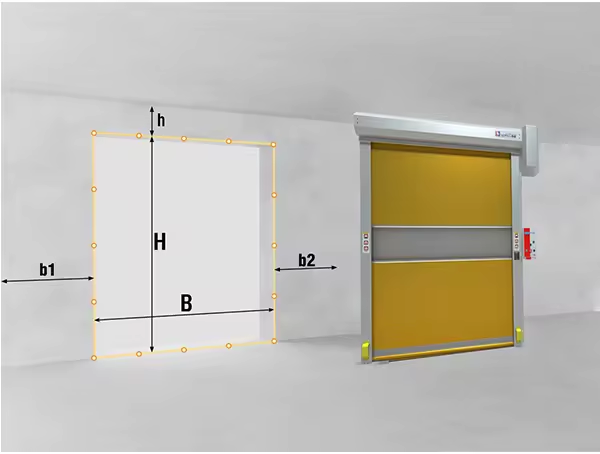

Before installing high-speed doors, a comprehensive site evaluation is essential to ensure doors function as intended and last as long as possible. Start by checking the sizes of doorways and making sure the chosen door fits. In addition, ceiling height, wall space, and floor conditions need to be evaluated. Examine the site’s traffic and how often different vehicles or people go through the doors to help decide the best speed and durability for the door. Also, take wind, temperature, and humidity into account as this can impact how the door is made and how well it works.

Check wiring and power supply to ensure a match with the door’s electrical needs. If automation will be needed or extra safety features like motion sensors or laser beams, check for the support to manage such systems. And finally, ensure the site meets all applicable building codes and regulations to avoid legal or operational issues post-installation. This will help make sure the doors will be made to best meet the needs of the environment and will work well for a long time.

Electrical Setup Requirements for High-Speed Door Installation

Having the right electrical setup is critical, as high-speed doors will operate more smoothly and last longer when properly set up. To begin, make sure the power supply is adequate. High-speed doors require different voltages and amperages based on the model, but most are in the 220V to 480V range. To alleviate the risk of overloading, dedicating certain circuits will also help. Adding circuit breakers and surge protectors will stop power overages and shorts, and will protect the setup. Grounding also needs to be conducted to help the setup’s electrical hazards and safety compliance.

More high-speed doors are coming equipped with advanced technology as more services utilize programmable logic controllers (PLCs). These more advanced systems will require even more precise connections. For this reason, follow the manufacturer’s guidelines and avoid using connectors to ensure there are no signal disruptions. As well as this, post-installation, be sure to do multiple tests to ensure there is full compatibility with the integrated systems. Things like remote operation, motion sensors, and other control devices will be able to make such integrated systems operate more efficiently.

Cleansing the electrical parts of the doors from time to time will help maintain their performance and lessen downtime. Things like stuck connectors and loose wires will create more problems in the future if not fixed. Be sure to keep updated with your area’s electrical codes and operational guidelines in order to ensure a proper setup.

Choosing the Right High-Performance Door for Your Application

When choosing high-performance doors, look for options that ensure functionality, durability, and efficiency, but keep the operational environment in mind. Here are five factors to consider when selecting high-performance doors:

Operational Speed

Doors with rapid opening and closing mechanisms are critical for applications where control of the environment and downtime must be closely monitored. Some doors can open and close in as little as 100 inches per second. Closing and opening this quickly improves the flow of traffic in and out of the space.

Door Strength and Material

The mix of materials that make up the door is the strongest indicator of longevity and high-performance doors. Some industrial applications may require reinforced rubber or even steel, while clean rooms may only require PVC doors.

Energy Loss and Insulation

In order to keep energy costs to a minimum, select doors that have insulating qualities in addition to controlling the door temperature. An insulating door with an R-value that meets or exceeds 7 is preferable.

Safety

Many high-performance doors have safety features that include sensors or motion detection, as well as an emergency stop function. Be sure to note and comply with safety regulations as they apply to doors in high-traffic areas.

Customizable Features

You can customize options for high-performance doors, such as different dimensions, colors, and extra features like wind and soundproofing. This ensures the door meets your operational needs and provides maximum performance and satisfaction.

By considering these elements, you will be able to select the most effective high-performance door for your application and enhance productivity and results for the future.

Tools and Materials Needed

Standard Installation Tools

There are a number of important tools that are key to making sure that the installation of the high-speed doors is done accurately and safely. Below is a list of five tools necessary for the installation.

Measuring Tape

Purpose: A measuring tape ensures that you get the dimensions of the doors and where the doors are going to be installed.

Recommended Type: It is recommended to get a measuring tape that has both metric and imperial measurements for flexibility.

Power Drill

Purpose: This tool is used to install the doors and to drill holes to make the installation easier.

Recommended Type: It is recommended that you get a cordless drill that has adjustable speed settings.

Level

Purpose: This tool is used to determine if the tracks and the door are perfectly aligned with the frame.

Recommended Type: It is recommended to get a bubble level or a laser level for high accuracy.

Socket Wrench Set

Purpose: This tool is used to secure the door components to the frame.

Recommended Type: It is recommended to get a multi-size set that is compatible with different bolts and nuts.

Safety Gear

Purpose: This gear is used to protect the installers while installing the doors.

Recommended Type: It is recommended to get safety goggles and a hard hat.

When the tools listed above are available for the installation of the high-speed doors, it will help make the installation run more smoothly.

Main Components of High-Speed Doors

High-Speed Doors Engineered Components

Let’s go over each component to better understand high-speed doors.

Door Panels

Purpose: Panels are the high-speed doors’ main structures and are the necessities for overall durability and insulation properties.

High-speed doors are equipped with weather resisitant and energy-efficient materials such as reinforced PVC, aluminum, or even composite materials.

Drive System and Motor

Purpose: This component is crucial for opening and closing the high-speed doors. It also ensures the doors are rapid to optimize workflow.

In high-speed doors, the latest technology includes the variable speed drive (VSD). This is the main contributor to energy efficiency and the reduction of wear on the components.

Control Unit

Purpose: This is the main component that enables the user to operate the high-speed door. It also has features for setting speed and the safety functions.

In high-speed door control units, modern programmable logic controllers (PLCs) and IoT for smart systems have been used as a main method for remote monitoring.

Safety System

Purpose: This component is to protect and prevent accidents in the operation of the door.

The door is designed to stop or reverse in the presence of an obstruction, so it is equipped with photoelectric sensors, light curtins and safety edges.

Sealing System

Purpose: This is used to regulate the internal environment’s temperature and control the presence of contaminants.

Innovations: New door seals provide better insulation and wear resistance, which contributes to lower energy costs.

Counterbalance System

Purpose: To aid in balancing the strain of the door to the motor and improve operational efficiency.

Common design: Incorporates tension springs or counterweights designed for smooth travel.

With these features and innovations, high-speed doors become an essential element in industries where efficiency, safety, and dependable control of access and environmental conditions are required.

Step-by-Step Installation Process

Door Delivery and Unpacking

Receiving and unpacking a high-speed door is crucial to a smooth installation. When the door arrives, check the shipment to see if anything is visibly damaged from shipping. Make sure that all parts are included, such as the door panels, motor, control system, and installation accessories, according to the manufacturer’s packing list.

Before you start, lay down soft padding to prevent damage during the unloading process, like the control panel and sensors. After unloading, sort the equipment and accessories systematically and place them near where you will be doing the installation to make the process quicker and easier. Make sure you have the installation manual, wiring diagrams, and any other documents. How you handle the equipment during this stage will play a part in the ease of the installation and the FUNCTIONING of the high-speed door later on.

Assembling and Installing Tracks/Guide Rails

The assembly of tracks or guide rails is crucial when it comes to how seamlessly a high-speed door operates. Before beginning any assembly, make sure to check that all guide rails included in your shipment are compatible with the door model in question. Also, check all rail tracks for visible damage before doing any assembly.

Make sure all guide rails are properly positioned and in accordance with the manufacturer’s instructions. It is your responsibility to make sure that they are aligned and leveled so as to avoid any operational issues or uneven wear and damage that could occur over time. Hook the guide rails onto the mounting surface. Make sure they are free of any and all obstructions and debris so that the high-speed door can move freely.

Use spacers or shims when making adjustments on uneven surfaces. For powered models of high-speed doors, the guide rails must integrate with the motors and electronic controls so that they can provide powered assistance as needed. Make all the required hook-ups based on the provided wiring diagrams. Finally, after assembly, test the mobility of the door within the tracks to make sure everything operates smoothly and is not hindered by the rails.

Reliably and accurately installing the most recent version of the high-speed door system can strengthen the attention of the system and improve its longevity.

Mounting the Door Panels

This part explains how important it is to install the door panels correctly to make sure the high-speed door works properly. First, unpack the panels. Before the alignment, make sure to check for any damage from shipping. Then, panel the door tracks, making sure that the panels are aligned correctly with the manufacturer’s. Then, lock the panels to the track with the suggested hardware, brackets, or screws, for stability.

Panels must be aligned and leveled to prevent movement issues. Also, if the panels are placed too closely to each other, they can also obstruct the opening and closing cycle. Windows of high-speed doors have incorporated safety systems that may include sensors or other means of guidance. Make sure to test these systems after the panels are aligned.

Also, more advanced models may incorporate lightweight and durable materials, such as reinforced PVC and aluminum, for the panels, which boosts speed and resilience. With these materials, follow the latest installation instructions or updates from the manufacturer. After installation, test the door to ensure the panels slide effortlessly along the track system and that no modifications are needed.

Installing the Motor and Control Systems

The next step of the high-speed door installation process is to configure the control systems and secure the motor in place. First, secure the motor to the prescribed bracket. This means that you’ll have to see if the bracket is correctly aligned with the operating system of the door. Many modern high-speed doors have high-end motor technologies, including, but not limited to, direct-drive systems and gearless motors. These kinds of motors not only function more smoothly, but they also require less maintenance. After the motor is secured, the next step is electrical wiring. As the manual describes, connect the motor to an electrical source and double-check that all of the connections are covered and secured in order to prevent short-circuiting.

Next, align the control systems with the motor and the type of door. Most new high-speed doors come with intelligent control systems, and they can be programmed for things such as speed, soft start/stop, and obstruction recovery. Use the most recent instructions to set the high-speed doors, and in case there are any performance issues, update the software. To improve safety and prevent accidents, the addition of motion sensors or photocells is highly advised. Once the high-speed doors are set, check the motor and control systems by opening and closing the system multiple times to check for any issues. If there is some inconsistency, tweak the tension settings or recalibrate some controls. In case some high-speed doors are sticking, perform some maintenance and software updates to improve the performance of the doors and reduce wear and tear.

Calibration and Programming of High-Speed Doors

To get the best results when it comes to the performance, safety, and efficiency of high-speed doors, the right calibration and programming must be done on them. In terms of adjustments, things like the operational adjustments, opening and closing speeds, tension, and limit settings would need to be modified. The latest doors have control panels and software that allow for adjustments and customization. Because of this, they can be fully integrated with other building systems.

Part of the programming is to prevent accidents with the configuration of safety measures, so things like motion sensors, photo-eye, and e-stop systems need to be part of the programming. There is more to the programming, like timers and cycle settings, which can be adjusted to manage the use of the doors so that the operational and non-operational traffic patterns can be adjusted and so that wear is limited. The latest technology comes with IoT solutions, allowing facility managers to track door settings whenever they want.

To have the best performance, software and recalibrations have to be done regularly to align with the latest safety regulations. If the right calibration is obtained, high-speed doors can be used commercially and industrially.

Incorporating Safety Features

When we put in high-speed doors, we need to put in the right safety features for personnel, goods, and job efficiency. Some safety features include safety beams, sensors, and touch safety edges. These features help identify if there is something in the way of the doors. Doors can be fitted with an auto-reverse feature, where the doors will retract automatically if something is in the way.

Modern high-speed doors can have breakaway panels. These panels will break away from the door and hit the wall instead of the door crashing into and damaging the wall. These features lower repair costs. When the door is moving, audible and visual signals will warn people nearby of the moving door. During power outages or technical failures, the doors should have a way to be manually overridden to keep access and security consistent.

With the right features, safety calibration, and maintenance, high-speed doors can be a reliable, safe, and high-performing solution. These doors will meet and exceed safety compliance.

Post-Installation Checks and Testing

Operational Testing of High-Speed Doors

After the fast doors have been installed, operational tests need to be performed to be sure that the doors operate safely and correctly. Do the doors satisfy their performance objectives, and do they function properly in a variety of circumstances? After the doors have been installed, tests need to be completed to ensure they are functioning correctly. The tests that need to be performed include checking the opening and closing speed, smoothness, and cadence of the door, and checking that the safety features are operationally correct (sensors, auto reverse, and emergency stops).

They also need to be checked to ensure that they are properly balanced and aligned. This can be critical to longevity, so they are not impacted adversely. The test will also need to be done under conditions that they will be exposed to post-installation. This includes tests that will be done under wind, extreme temperatures, and freezing conditions to test the operational limits of the doors. The door diagnostics can be integrated into the tools to record closing and opening cycles. These doors can record performance metrics that can assist in determining adjustments that need to be made. After all tests are completed, the doors can be issued their performance certificates. The doors can also be issued their safety standards compliance certificates.

Verifying Alignment and Sensor Functionality

Once high-speed doors are installed, the first thing to do is to check the alignment and sensor functionality to provide the optimal operating system and to ensure safe operating system functionality. If the doors are not aligned, they can lead to malfunctions and extreme system wear, which can, in turn, lead to diminished system life. To check alignment, technicians use laser alignment or other specialized measurement equipment to perform the alignment check. Verifying the alignment of the tracks and rollers is necessary, but not sufficient to ensure that the doors are and will remain unencumbered by any excess pressure of the system.

Because the automation of the high-speed doors relies on the proper operation of the sensors, they must be checked fully and thoroughly. These sensors, which consist, in part, of a safety edge, a motion detector, and a photeye, must be responsive to system movement to come into compliance with system safety. Diagnostic tools, on the other hand, which come with many modern high-speed doors, can assist in the sensor check by reporting via an onboard computer or sensor, which can simplify some of the sensor responsiveness checks via the system. Lastly, to ensure the doors are operating most efficiently, it is necessary to regularly perform the checks and adjustments as discussed in this document, which will ensure the doors provide optimal safety.

Customizing Control Options

Enhancing controls on high-speed doors post-installation allows businesses to customize their operational needs. Advanced control capabilities are built into most modern high-speed doors. Adjustable speeds, smart access controls, programmable timers, and other features enhance safety and add operational efficiencies.

Most of these controls can be customized post-installation via user-friendly systems, remote access systems, or software. This makes post-installation changes to operational workflows or security levels seamless. As an example, access controls integrated with warehouse management systems can routinely unbolt doors for forklifts during peak volume to eliminate operational delays. Motion sensors and touchless access controls are other examples that can increase safety and cleanliness in food and pharma environments.

Custom control integrations must be in place to maintain optimal performance. Integrated control systems and regularly scheduled firmware updates are one best practices that manufacturers put forth. Other manufacturers put forth mobile apps that help staff monitor and set doors in real time to maximize operational convenience. Adapting high-speed doors and improving controls results in added functionality and extended doors’ operational lives.

Maintenance and Aftercare

Routine Inspections and Cleaning

High-speed doors can perform for a long time when kept in proper maintenance. Below are some specific maintenance, cleaning, and inspection tasks that need to be done frequently.

Check the Door Panels and Seals

Check the door panels and the seals for any visible cracks, damage, or wear. Seals that are damaged can lead to a loss of insulation and an increase in noise during operations.

Moving Parts Lubrication

Moving components like hinges and rollers need to be lubricated to reduce wear and tear mechanically and increase efficiency.

Clean the Surface of the Door

To keep the panels free of abrasion, use a non-abrasive cleaner to eliminate the dust, grime, and dirt to keep the panels clean.

Tighten and Examine the Fasteners

Screws, bolts, and brackets should be fastened tightly to avoid any instability during operation.

Test All Safety Systems and Sensors

Do quick tests to check that detection systems and sensors like photo eyes are stopping the doors correctly when something is in the way. Replace the components that don’t work right away.

If businesses do the tasks mentioned above, the high-speed doors can be maintained, and the efficiency and safety of the doors can be increased, and the chances of malfunction can be reduced.

Scheduled Maintenance Importance

High-speed doors allow quick access to and from a facility while also providing control over the internal environment. Scheduled maintenance is important to keep the doors functional, as issues that arise from operational inefficiencies because of door failure can align with inefficiencies in primary operations. Maintenance will also prevent issues from becoming much larger in the future with door components and systems.

From an operational standpoint, having functioning safety features on doors means that safety systems can be relied upon to reduce accidents, which is a potential concern in every facility. The most recent recommendations indicate that regular service of the door motors and inspection of all the door components can maintain performance, thus avoiding the need to make long-term repairs that would be much more costly. Cross doors and proximity sensors will keep the doors in an operationally safe state. Having maintenance plans directed towards proactivity will minimize safety and operational non-compliance breakouts.

Training Users for Proper Operation

Although it might seem obvious, employee training is an important aspect of using high-speed doors efficiently and safely. Users must understand the basics of the doors, including how they work, the safety measures, and how to respond to an emergency. For training, it might be helpful to go over the instructions before outlining the various functions of the control panel, the steps that should be taken to operate the door, and the problems that should be watched for (strange noises, door movements that appear to be out of the ordinary, etc.).

In the interests of safety and to reduce the likelihood of doors being misused, an emphasis should be placed on the instructions that are provided by the door’s manufacturer. Preview any training, videos, and slates that are provided by the manufacturer, as these may assist. Refresher training should also be used to keep employees apprised of recent changes in safety, technology, and door operation techniques. When employees are aware of the functions of the doors and the doors are in a safe environment, the business is able to get more value out of the high-speed doors.

Cost Factors in High Speed Door Installation

Overview of Price Drivers

High-speed doors don’t have a fixed price, and they can vary based on different factors. Here are some of the most important price-determining factors:

Door Size and Customization

When a door is bigger or if it needs to be customized differently, that usually increases the price. Customization could include different designs or different branded colors. This could include specialized finishes to match the look or colors of the facility, logos, or other finishes.

Material Choice

Material affects the price of the doors, and some materials include aluminum, steel, and PVC. PVC is usually cheaper because it’s for lighter applications. Steel is more expensive because it is more durable, and Aluminum is in the middle because it is strong, light, and even more durable than PVC. Some doors have insulation for energy efficiency, and they are more expensive than the other materials.

Motor and Automation Technology

High-speed doors are usually expensive because the technology is more advanced. They rely on powerful motors along with a complex automation system. Some features that drive the price up are a variable speed drive, soft start motors, and some sensor-activated systems.

Safety Features and Compliance

High-speed doors are generally more expensive because of the systems added to them. Some safety systems include photoelectric sensors and safety edges. They have also added more Emergency stop mechanisms. Doors that comply with routes, some chains, or other systems, and have added fire safety compliance.

Installation Environment

Depending on the door type, the installation location may impact the overall costs. Weather conditions may require the outdoors to have doors with extra durability. Extreme weather and corrosion may require the use of special doors; this includes all doors with specific use, like the food industry, and can increase overall costs.

Maintenance and Warranty Options

There can be doors with the price of packages that include extended warranties, offer professional maintenance, and come with premium certifications. There should be a fact taken into consideration with the price of the ease of maintenance with the doors for the choice of systems and materials.

Having the outlined options, it can permit businesses the ability to understand all the factors better aligned to their operational capabilities and limitations, as well as their budgets. Getting high-speed doors that are durable and of high quality will help the business to reduce maintenance and ensure efficiency in the long run.

Typical Price Ranges for High-Speed Doors

The kind of high-speed doors that you select greatly determines the speed of the doors. The following are some types of high-speed doors and their prices:

PVC Roll-Up Doors

Price: $3,000 – $6,000

Features: Low-weight and flexible. Best for internal division within a manufacturing facility or warehouse.

Insulated High-Speed Doors

Price: $7,000 – $12,000

Features: Best for temperature control environments. These doors are energy efficient and protect environments from heat loss.

Rubber High-Speed Doors

Price: $10,000 – $20,000

Features: Best for heavy-duty use and extreme weather. These doors give you durability, impact resistance, and extreme weather.

Aluminum High-Speed Doors

Price: $8,000 – $15,000

Features: These doors are good for the outdoor environment. They are corrosion-resistant and combine aesthetic and functionality.

Food-Grade High-Speed Doors

Price: $5,000 – $10,000.

Features: They are suited for cleanroom environments with high hygiene regulations. They offer easy-to-clean and hygienic materials.

Note that the ranges listed above are to be adjusted based on the door’s size, automation, customization, and features like safety sensors.

Impact of Professional Installation on Total Cost

Doors that operate at high-speed are an important addition to many businesses. The cost for these doors, however, can be considerably more expensive because of the highly variable associated installation costs. Depending on the setup, the installation can actually prove to be beneficial for the setup. Last year, the best option for setup was hiring seasoned technicians who were guaranteed to perform all of the required actions(s). They ensured nothing was out of place, and the doors were guaranteed to comply with all safety regulations. The opposite scenario is applicable if the installation is performed by unprofessional workers. The opposite of everything stated previously would be the case, plus some additional costs to the business in maintenance and safety as a result of increased risks.

To mitigate the consequences of a bad installation, a business can opt to use one of the installation professionals. As stated in the former paragraph, the routing of the doors is the setup that allows high-speed doors to operate. Choosing this setup ensures that the maintenance(s) will be spaced out by a considerable amount. In addition to this, some installers do offer warranties and maintenance, but only if the installation was performed by one of the professionals. Installing high-speed doors is a calculated investment that aims to provide guaranteed optimal service.

Common Mistakes and Tips for Success

Dangers of DIY Installation

While saving money on your high-speed door installation may feel good, doing your own installation may create problems that are much more difficult to fix. Here are five problems that may happen if you install your own high-speed doors:

Faulty Calibration

High-speed doors must be calibrated with a high degree of precision. If a door is calibrated incorrectly, it may not seal properly, it may become an energy efficiency detractor, and its longevity may be severely impacted. Research shows that 30 percent of operational costs will go towards energy loss if high-speed doors are improperly calibrated.

Lost Safety Features

Investing in safety features like motion sensors and auto-reversing will go to waste if high-speed doors are not installed correctly. Having high-speed doors with improperly installed safety features will lead to a greater risk of injury and even loss of life, especially in food processing environments.

Risk of Structural Damage

The high-speed door system may do more than just outline and install the portal. Having no experience with a framing system, including the door’s casing and support, may lead to the creation of new structural weaknesses. The costs of repairs, if the setup is done incorrectly, can be extensive.

Mechanical Failures

Do-it-yourself installations often leave critical steps undone, which can lead to a host of other new problems. Crank adjustments, setting the right level of spring tension, and calibrating the system so that the high-speed doors work properly will be overlooked to ensure the longevity of the door. Overlooking so many steps can even lead to a door’s longevity being cut in half, if not more.

Void Warranties

Most high-speed door manufacturers will only honor their warranties if you get the doors installed by professionals. If you install the doors yourself, you could lose the warranty, which means you would have to pay for any repairs or replacements.

By using certified professionals, you eliminate these risks, and you get to protect your investment for the long haul. When it comes to the efficiency and functionality of your commercial operation, high-speed doors are some of the most important components. Never overlook how important proper installation is.

Value of Relying on Certified Experts

Installing high-speed doors is a multi-faceted task that must be completed in a timely and methodical way in order to stay in line with regulations and specifications of the manufacturer and the industry. Certified experts simplify this process. They offer a high level of efficiency, which enables them to save time and solve problems before they become complex. This means that they stay up to speed and modern with the latest technology and installation methods. They provide the most effective and cutting-edge solutions through continual training and installation certification.

Having certified installers will help better understand the regulatory requirements and safety standards of high-speed doors in order to avoid compliance violations. In addition to optimizing the distance of doors and how effectively they can be used, they significantly reduce the downtime in your operations, which creates a substantial return on this investment. Certified professionals really help to protect your warranty and offer a long-lasting solution that meets the needs of your business.

Key Points to Maximize Durability and Efficiency

Regular Maintenance and Inspection

Regular maintenance checks are essential to monitor potential problems and address them proactively. According to research, companies conducting monthly inspections can save as much as 30% downtime. Remember to clean and lubricate the motor systems, seals, and rollers.

Quality Installation by Certified Professionals

Make sure the door is installed by certified professionals who adhere to the manufacturer’s specifications and industry standards. In the industry, it is estimated that proper installation can increase the lifespan of high-speed doors by as much as 20%.

Optimal Operating Conditions

Always make sure the area around the high-speed door is clear of debris and other obstacles. This helps avoid the mechanical stress of the doors. Also, pay attention to operational cycles to avoid overuse. Each model has its own overuse constraints. Overuse is considered to be more than 150,000 cycles per year to maintain the doors’ operational effectiveness.

Invest in High-Quality Materials

When it comes to choosing the high-speed doors, pick the ones made of reinforced PVC or aluminum. Research indicates that the selection of robust materials in the construction of the doors can add a 40% improvement to the wear and tear of the doors, especially in environments of heavy usage.

Upgrade to Smart Systems for Automation

The use of smart systems and automation can further enhance operational efficiency. In terms of costs, smart technology can represent 15% savings as a result of reduced unnecessary openings and closures, and also savings in climate control.

Conclusion

Long-Term Value of Professional High Speed Door Installation

Having high-speed doors installed professionally brings many advantages in the future. Investing in them brings business growth, efficiency, and scalability. Some of the advantages include the following.

Improved Safety Standards

Professionally installed high-speed doors come with extra safety features. Some include motion detectors and emergency stop functions. Because of these features, the risk of accidents is reduced, and the doors comply with safety regulations.

Improved Energy Efficiency and Savings

Professionally installed high-speed doors create better seals. Better seals help with climate control and can help businesses save 20% on energy costs over time.

Lowered Maintenance Costs

Disregarding professional installation can lead to frequent malfunctions and costly repairs. On the opposite end, professional installation can reduce the cost of repairs by about 25% on average.

Increased Operational Efficiency

Professionally installed high-speed doors can integrate with other automated systems. Integration with these systems can reduce cycle times and increase productivity by 15%, benefiting operations in cold storage and food processing.

Benefits for Safety and Sustainability

Enhanced Workplace Safety

Professionally installed doors help improve workplace safety. Studies have shown that professionally installed speed doors can reduce safety incidents by 30%.

Improved Environmental Control

High-speed doors improve energy efficiency by 40%. By keeping the controlled climate in the facility from escaping through the doors, a more stable working environment can be created.

Reduced Contamination Risks

Doors that open and seal quickly can improve environments with strict levels of hygiene, like food and pharmaceutical processing. They can help keep dust, debris, and contaminants like a barrier.

Lower Carbon Footprint

The speed doors can help your organization reduce your carbon footprint as they help reduce energy loss and improve overall energy efficiency. By utilizing speed doors, organizations have been able to reduce their greenhouse gas emissions by as much as 25%.

Compliance with Safety Standards

In today’s market, speed doors can adhere to strict safety and health standards, and therefore can be compliant with any applicable laws. This protects your employees and the environment while also lowering the chances of fines from litigation.

Impact on Business Success

These high-speed doors have been great for our business. They have allowed us to save energy, which improves our workplace efficiency. This positively impacts our revenue. Their safety and sustainability have also been a relief for us, as we know we are meeting our regulations while also being environmentally safe. These doors have also helped us with our goal of reducing costs and increasing productivity.

Frequently Asked Questions (FAQs)

What should businesses in the industry expect from high-speed door installation?

Businesses should be prepared for a professional installation of high-speed rolling doors that improve door cycling time and decrease productivity loss. Industrial high-speed doors and high-performance rolling doors provide fast opening speeds, high reliability, and low maintenance for interior and exterior door openings. A qualified distributor can provide recommendations for fabric doors, stainless steel doors, or folding doors, depending on the utility, traffic, and environmental needs.

How does a rolling door installation differ from a standard garage door installation?

The focus of high-speed rolling door installations is on fast operation, safety sensors, and durability through heavy usage cycles compared to a standard garage door. High-performance doors have been designed with components like reinforced curtains, strong drive systems, and auto controls that facilitate frequent opening and closing. More specialized procedures for installation and maintenance ensure the doors are durable and that there is a consistent opening speed, while also ensuring safety is not compromised.

Are overhead door systems suitable for both interior and exterior applications?

Along with high-performance doors, overhead door systems, including commercial overhead, can be specified for interior or exterior installations. Fabric doors or high-speed rolling doors are typically used for indoor applications to separate work areas, while exterior doors are focused on weather resistance and security. The durability and energy efficiency of doors have been improved with the addition of rubber seals and stainless steel hardware to create a weather-tight seal.

What are the facility requirements before scheduling a high-speed door installation?

As part of facility readiness, the structural support for the door frame, door travel clearance, and electrical supply for the drive and controls should be confirmed. For commercial doors and industrial doors that open and close at higher speeds, make sure the space overhead is unobstructed and the mounting space is solid. The dealer will determine which type of door: sliding, folding, or high-performance rolling, best suits the traffic and workflow to enhance productivity.

Can rubber seals and other accessories be added during high-speed door installation?

Certainly, to help with insulation and the protection from dust and drafts, the rubber seals, brush strips, and weather sealing are installed. Along with these, vision panels, kick plates made of stainless steel, and auto sensors are functional add-ons. Sealing the doors appropriately to the frame does improve the thermal performance of the doors and saves on utilities. It also improves the durability of the doors and reduces the maintenance the doors require.

How do high-speed door installations impact productivity in busy commercial door locations?

The high-speed rolling doors and high-performance doors open and close a lot more quickly than the rest of the doors that are available, so reducing wait time and congestion continues to improve productivity. Along with that, these improvements improve the operational workflow because the fast and reliable performance of the doors streamlines the logistics and reduces the loss of heated or cooled air from the HVAC system. These abilities help employees to work more efficiently and also improve operational throughput from the door.

What common troubleshooting or maintenance should owners expect after a new door installation?

Regular checks and preventive maintenance ensure doors continue dependable performance. Troubleshooting steps include sensor checks, closing adjustments, and springs or drive tension, rubber seal inspections, and control setting checks for opening speed. Many dealers provide service agreements for the installation and maintenance of doors to avoid prolonged operational interruptions and ensure high-performance doors provide long-term dependable service.

Are there auto or automated options available with commercial overhead and high-speed rolling doors?

Sure, most commercial overhead and high-speed rolling doors allow for automated control, including motion sensors, remote control, and building management system integration. Automation provides seamless workflow, enhanced safety with presence-detection, and programmable opening and hold-open time control. Optimal operational efficiency and custom site requirements are achieved when the right automated features are chosen during the installation of new doors.

Reference Sources

- MCU System-Based Intelligent High-Speed Elevator Door Operator Fault Analysis and Research

- Key Findings: This study focuses on fault analysis in high-speed elevator door systems, emphasizing the importance of installation technology to prevent hazards. It also examines the operational state of these systems throughout the year.

- Methodology: The research uses an MCU-based system to monitor and analyze faults during installation and operation.

- Read more

- Aerodynamic and Dynamic Response of Platform Screen Doors to High-Speed Trains

- Key Findings: Investigates the impact of aerodynamic pressure waves and mechanical vibrations on platform screen doors when high-speed trains pass through underground stations.

- Methodology: Field studies were conducted to measure the aerodynamic and dynamic responses under real-world conditions.

- Read more

- Designing a Cost-Effective Encoder for High-Performance Doors

- Key Findings: Explores the development of a cost-effective encoder for high-speed doors, particularly for ASSA ABLOY systems, to enhance feedback and automation.

- Methodology: The study evaluates various encoder designs to identify the most suitable solution for high-speed doors.

- Read more

- Testing and Analytical Evaluation of Doors

- Key Findings: Discusses methods for evaluating doors, including those designed for high-speed applications, to predict their response to applied loads.

- Methodology: Analytical and experimental methods are used to assess door performance under different conditions.

- Read more

- Integrated Position and Speed Control for Rail Transit Doors

- Key Findings: Proposes an integrated control method for rail transit doors, focusing on speed and position control to improve performance.

- Methodology: Utilizes a speed-current loop structure for precise control during different operational stages.

- Read more