Selecting high-speed doors for the first time in an industrial or commercial facility plays a critical role in operational efficiency, security, and long-term expenses. With options such as roll-up doors, overhead doors, and speed doors, understanding high speed door cost differences can feel complex. This guide breaks down the key cost factors—materials, features, installation, and maintenance—to help you budget accurately and make an informed investment for new construction or facility upgrades.

Introduction to High Speed Doors

What Are High-Speed Doors?

High-speed doors are unique doors that are made to close/open in a much quicker fashion than a normal door. Because of their build, they are able to enhance a company’s operational efficiency and keep the company’s environment intact. These doors are built using strong materials that include PVC and reinforced fabrics. Because of this, they are great for places like warehouses, food-processing plants, and logistics centers. These types of doors also come with a lot of valuable advantages in companies like logistics, where operational standards are strict and a lot of downtime may result in contamination, poor air quality, or other operational losses.

Why Cost Matters for Commercial Buyers

Cost is crucial for commercial buyers evaluating high-speed doors, as this is a system that not only impacts the up-front costs but the operational costs as well, and is a significant operational budget. According to the most recent insights, the high-speed door industry has a wide variety of doors with different costs. Costs can be based on features such as size, construction materials, speed, and additional features like insulation and smart technologies. While lower cost doors tend to have a more attractive ticket price, those doors tend to underperform in demanding environments, which can place doors at a higher risk of costly service and repair.

High-speed doors have the potential to provide commercial facilities with operational cost savings. They create a tighter seal, which, with less air exchange more internally retained air means less operational spending on heating and air conditioning. Additionally, because of the operational cost savings the doors provide, there are potential savings as well on the facilities’ operational inefficiencies in the workflows. These all increase the doors’ return on investment, making them a cost-effective choice for commercial doors. All of this together provides commercial buyers with a complete view of the door system operational costs.

Overview of High Speed Door Costs

Typical Price Ranges: 2026 Market Update

Factors like size, materials, features, and customizations play a big role in how much high-speed doors will cost in 2026. Recent market analysis shows that high-speed doors, as a general rule, will cost between $3,000 and $10,000, and in some cases more than $20,000. Many of the doors in this price range will use premium materials and be more durable, with added features like safety or energy efficiency technology. Doors that use high-quality components can help lower maintenance costs. Doors aren’t the only thing that comes with a price, though; set aside some money for the complexities of installation. Always consider the cost of maintenance when budgeting for a set of high-speed doors to ensure that you have a high level of functionality, quality, and cost efficiency.

Key Factors Influencing High Speed Doors Cost

Material Quality

The materials chosen to make a high-speed door will impact the cost of the unit. Using options such as reinforced steel or PVC will cost you more. These materials have more durability versus the cheaper options, which have a compromised longevity.

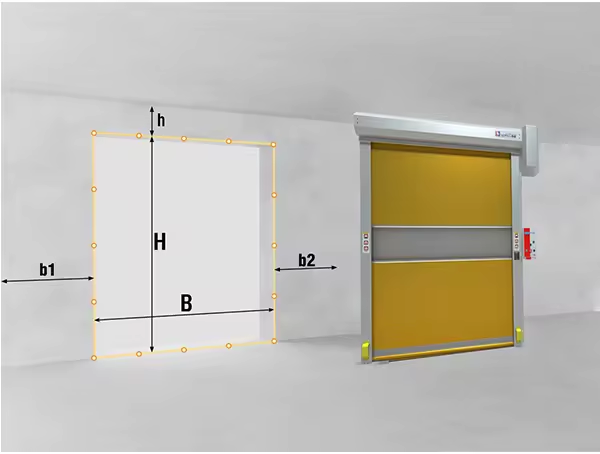

Door Size and Specifications

Bespoke and larger doors come at a premium. These unique custom designs often come at an added manufacturing time and resource cost.

Technology and features are crucial for commercial doors to enhance efficiency and safety.

Automated control systems, smart sensors, and specialized sealing systems can all add to a unit’s cost. These systems are designed to improve overall performance.

Installation Complexity

The cost of installation can be impacted by the amount of structural changes that are required. Doors that need custom fittings to be placed or that have complex structural integrations will cost you more.

Brand and Warranty Coverage

Better engineering and reliability of a component lead to higher prices. This is often the case with larger brands that have a solid warranty. They often reduce long-term maintenance needs which can lower the overall costs.

Material, Size, Speed, and Safety Features

Engineers design high-speed doors with materials that meet the demands of modern industrial and commercial facilities. They use durable PVC, reinforced aluminum, and corrosion-resistant steel to increase door longevity and ensure they withstand harsh environments. These materials provide excellent durability for high-traffic areas.

The dimensions of the of the high speed doors varies and so does the customizability of their dimensions. The sizes of the doors are made to maximize functioons of the space. Large industrial areas and small passages can be made. However, the large ones need to be reinforced for stability and safety.

An essential property of high-speed doors is their great speed. They can open and close doors in less than 60 inches per second. This greatly helps in saving climate control and energy. The efficiency also helps in reducing the workflow in manufacturing.

The most important part of high-speed doors is the safety features. These parts are built-in sensors to detect objects and people, emergency stops, and soft bottom edges to keep people from getting hurt if doors close unexpectedly. Furthermore, most new high-speed doors are designed with international safety standards in mind and may have clear parts to see through. These things keep the doors working and keep people and things safe.

Commercial & Technical Trends

Latest Innovations in High Speed Doors

The past few years have seen developments in the high-speed door industry. Innovations include improvements in efficiency, safety, sustainability, and smart technology integration. With the onset of IoT technology, high-speed doors can do real-time monitoring. They can also do predictive maintenance to decrease downtime and lengthen the life of door hardware.

The door industry has also developed the use of composite fabrics and lightweight alloy doors, which are more energy efficient and cost-effective. Doors now also offer more insulation features, which are beneficial in heating and cooling-controlled environments.

Touchless door systems are now available, utilizing motion and facial recognition, ideal for high-traffic areas. Included in the touchless systems are sanitizing stations, which have improved safety in the food and pharma industries. Eco-friendly systems are also available, incorporating sustainable building materials, high-speed doors, construction energy efficient drives, and reduced overall energy consumption.

The industry has continued to embrace the use of technology for improvements in safety, eco-friendliness, and smart technology. These improvements are necessary to keep pace with the speed of change in the world.

Sustainability and Energy Efficiency Trends

Sustainability and energy efficiency are being integrated more and more into the designs and functionality of high-speed doors. Departing from more traditional doors that would basically use the same types of materials as construction, modern high-speed doors conserve energy, using advanced insulation materials and airtight sealing systems. These systems improve climate control and reduce heating and cooling costs. Additionally, doors that operate at high speed improve energy efficiency by keeping the doors from being open for long periods of time, which is especially important for temperature-sensitive environments.

To combat ever-growing concerns about the environment, more and more manufacturers are using sustainable materials like recyclable metals and other bio-composite materials. Some designs also include doors that have energy regen cells embedded into them that capture and reuse energy from the door’s opening and closing cycles. These efforts help drive the doors toward meeting modern energy efficiency standards and circumvent the frustration of having to design for the ever-growing sustainable industrial solutions. These advancements drive down operational costs while also demonstrating the industry’s maturing focus toward sustainable and energy-saving design.

Types of High Speed Doors & Their Cost Differences

Roll-Up vs. Sliding vs. Folding High Speed Doors

Roll-up doors are cost-effective and space-saving, sliding doors offer sleek aesthetics and moderate costs, while folding doors provide maximum opening but are pricier.

Detailed Comparison in Tabular Form:

| Parameter | Roll-Up | Sliding | Folding |

| Cost | Low | Moderate | High |

| Space | Saves | Moderate | Needs more |

| Opening | Partial | Partial | Full |

| Aesthetic | Basic | Sleek | Luxurious |

| Usage | Industrial | Residential | Premium |

| Durability | High | Moderate | High |

| Maintenance | Low | Moderate | High |

Specialized Options: Insulated and Heavy Duty High Speed Doors

Thermal insulation efficiency is a high priority for many large facilities and industries. Insulated high-speed doors keep temperatures steady while saving energy and helping to meet industrial regulations. Constructed of high-performance sealing systems and insulated panels, these doors help reduce heat transfer and ensure durability.

Heavy-duty high-speed doors are designed for difficult active industrial environments and are made from high-strength materials. They are great for large facilities that experience high levels of traffic, severe environments, or a lot of heavy equipment. They are designed to provide great impact resistance and longevity, reducing maintenance costs. These also may incorporate safety systems, breakaway systems, and reinforced tracks for high-level operational environments.

Insulated doors are more expensive because of their effective flexible layered design that is more expensive to manufacture. Thermally efficient doors are heavy-duty as well, which could add more upfront costs for the customer. Both doors save costs in the long run by improving operational efficiency, saving maintenance costs, and saving energy due to reduced energy usage. The specialized doors will depend on the unique needs of the business and the operational needs of the company.

Installation Costs

Labor and Site Preparation

The initial steps before installing high-speed doors can significantly affect overall costs. These steps include reviewing the door location, adjusting the doors to match site conditions, and confirming proper fit. Because of the complex internal mechanisms, a qualified specialist must handle the installation to ensure reliable performance.

The site will need to have any pre-existing doors removed, and will need to be cleaned. If the site is going to have high-speed doors, the structure may need to be reinforced as well. The preparation steps listed above and any other steps will cost money, and the length of the prep steps will depend heavily on the surface of the site and how much access the site provides. Curtis Doors are complete with high-speed safety mechanisms and automation. These can be expensive and will take a lot of time to install, so make sure the site is ready to go.

High-speed doors can be expensive, so to lower costs, businesses need to make sure that service providers are properly vetted and that the site is ready before the installation. Prepping the site will lower the cost and will make it so that the doors can function properly as soon as they are installed.

Typical Install Price Breakdown

If you want to install high-speed doors, you need to take into account several elements that contribute to the total costs. Here is a cost breakdown based on up-to-date information:

Door Unit and Materials: This is the biggest cost contributing to your high-speed door installation, and can cost you anywhere between $2000 and $10000+, depending on the size of the door and the degree of customization that you want. Things that contribute to high costs include the size of the curtain, tracks, and other customizable hardware components.

Labor Costs: To ensure that the doors can function properly, you will need to account for the costs of professional installation. This can range between $800 and $2000, depending on how complex the installation is, the on-site conditions, and the geographical area.

Electrical and Automation Integration: If your doors are high-speed, then there is a door that integrates with automation and control systems (like motion sensors). This costs anywhere between $500 to $1500, depending on how advanced your automation system is.

Site Preparation: When prepping the installation site, there are several things that can cost $200 to $1000. Things you may need to do are: clear your area and add/ensure structural support.

Additional Features and Customization: If you want customizations and extra features, such as designs for fires and insulation, these can easily add thousands to your final cost.

Typically, the overall price range for installing high-speed doors is $4,000 and can go up to $15,000 or more, depending on many of the aforementioned factors. For estimating, it is recommended that businesses reach out to knowledgeable vendors for a more tailored quote.

DIY vs. Professional High-Speed Door Installation: Pros & Cons

When deciding between a DIY approach and hiring a professional for high-speed door installation, it’s essential to weigh the benefits and drawbacks of each option carefully. High-speed doors are critical for business operations, and the approach you choose can significantly impact the door’s performance, safety, and longevity.

DIY Installation

Pros

Cost Savings: One of the primary reasons businesses consider a DIY installation is the potential to save on labor costs.

Flexibility: DIY projects allow you to work on your schedule without waiting for a professional service appointment.

Hands-On Learning: Installing the door yourself provides a firsthand understanding of its mechanics and setup, which might be useful for future maintenance.

Cons

Complexity: High-speed door installations often require technical expertise, especially for automated systems. A lack of experience can lead to improper setup or operational issues down the line.

Safety Risks: Without professional knowledge, there is a higher risk of injury during installation or errors that affect workplace safety.

Equipment Requirements: Installing a high-speed door frequently demands specialized tools and equipment that may not be readily available.

Professional Installation

Pros

Expertise and Precision: Professionals are trained to handle all aspects of high-speed door installation, ensuring optimal performance and safety.

Time Efficiency: A skilled technician will complete the installation much faster than an untrained individual, minimizing business downtime.

Post-Installation Support: Many professional installers offer warranties and ongoing support for maintenance and repairs.

Cons

Higher Initial Costs: Hiring professionals can be more expensive upfront due to labor fees.

Dependence on Scheduling: Depending on the service provider’s availability, there might be delays in completing the installation.

Ultimately, the decision between DIY and professional installation depends on the business’s budget, resources, and technical expertise. For complex or heavily used high-speed doors, professional installation is typically recommended to ensure long-term functionality and safety compliance.

Benefits and ROI Considerations

Energy Savings and Productivity Gains

High-speed doors are meant to boost operational productivity and energy efficiency. The doors’ rapid open and close cycles reduce air transfer and energy loss, making them ideal for temperature control. Maintaining COLD storage facilities where internal temps are critical costs more efficiently because high-speed doors reduce energy loss and help keep your facility temp. controlled.

High-speed doors reduce downtime and help streamline workflow. The quick open and close cycles reduce wait time for people, vehicles, and equipment, thus enhancing operational efficiency. In sensitive environments, high-speed doors help streamline workflow. Modern, high-speed doors are equipped with advanced automation, which includes motion sensors, touchless access, and a system to speed things up and keep your space clean.

It is compelling to think about what investing in high-speed doors offers a business. It is easy to think about the decreased operational costs, the improved facility operations, and sustainable work environments. It is the extended energy savings and improved operational efficiency that offer the facility a better return on investment.

Security and Compliance Advantages

High-Speed doors improve the flow of traffic in your facility while keeping your employees safe and meeting government regulations. Because high-speed doors open and close quickly, employees are not as exposed to the elements, outside, and the doors can close before an unauthorized person can gain entry. Some doors are built with more security features like locking mechanisms and access control systems, which can provide extra intruder protection.

High-speed doors can meet industry regulations around food safety, cleanrooms, and fire safety. Warehousing, food processing, and pharmaceuticals have strong regulatory requirements around contamination control and environment. High-speed doors are strong and built with robust materials to last. Smart features like automated access controls and monitoring systems help businesses keep flow in the facility, secure access to the area, and meet the regulations.

Safety Features and Regulations

Required Safety Standards in 2026

New safety measures are coming that high-speed doors must comply with by 2026. They detail how the doors will operate and how they will protect the user. Among the most important measures is the compliance with EN 13241. This is a safety requirements guideline for doors, gates, and barriers used in the industry and in commerce. This guideline will make sure that high-speed doors incorporate safety components, such as photocells, pressure-sensitive edges, and advanced emergency stops, so that they are as safe as can be, avoiding accidents and injuries in the course of the work they will be doing.

Also, for the first time, Door manufacturers must follow the ISO 45001 Standard to ensure workplace safety and add devices that protect the safety of the operators to be in compliance with it. Additionally, the manufacturers must also ensure the high-speed doors conform to the fire resistance standards. In the USA, you will have to make sure they comply with the UL 10B/10C standards. These are standards that ensure the high-speed doors will work as barriers in the event of a fire.

As of 2026, the Installation of high-speed doors will be required to be as safe and as guaranteed as possible. It must comply with all of the new measures for advanced monitoring and automation, from the malfunction and blockage detection systems to the monitoring and control processes. Also, they will have to comply with new standards in insulation and energy efficiency to satisfy the new standards of ISO 50001. All of these objectives will ensure Installation of high-speed doors will be safe and guaranteed in 2026.

Compliance Costs and Optional Upgrades

The use of high-speed doors in industrial and commercial applications requires adhering to various policies that may affect cost investments and expenditures over time. Companies must budget and pay for details such as safety policy compliance, energy loss prevention, ISO 9001 certification for quality management, ISO 50001 certification for energy management, and environmental policy compliance. These details tend to cover the doors for safe, reliable, and durable operation within legal and environmental policies for a longer duration than the doors themselves.

Also, vendors often develop additional upgrades to high-speed doors in order to improve operation and longevity. Some of these additional upgrades include improved safety with new advanced sensors, energy-saving reinforced construction for high-wind zone use, more energy-saving reinforced construction with added smart systems for integration with building automation, and added systems for high-speed doors. These additional upgrades help operations, reduce maintenance, and contribute to sustainability policies. A thoughtful combination of compatibility and additional upgrades will improve the investment in high-speed doors.

Maintenance and Long-Term Ownership Costs

Routine Maintenance Needs

Proper maintenance of high-speed doors ensures that they run efficiently, last a long time, and stay safe to use. This includes lubricating moving parts, checking tracks for debris or damage, and testing control systems. Cleaning edges and sensors also helps doors from malfunctioning. Maintenance can be scheduled for a month, three months, six months, or a year and is dependent on the doors and the environment that surrounds them. For example, a door in a busy warehouse will need to be serviced more than a door in an office. Some high-speed doors also need updates to their software to prevent the doors from malfunctioning or losing important features. Maintaining doors to keep them from breaking helps save the owner money in repairs and also extends the time that the doors can be used, which is a big help in the long term.

Cost of Repairs and Parts

The price of high-speed door repair will depend on the type of door, how bad the problem is, and what parts are needed. If the tracks, sensors, or motor systems are worn out, the repairs will cost anywhere from hundreds to thousands of dollars. Repairing broken panels costs between $200 to $500, and replacing the whole motor will cost over $1,000. Also, high-speed doors that have Smart Tech will have to be repaired by someone who is able to use the more expensive parts and services because of the higher costs.

To reduce high costs, service providers should be contacted to keep the door in working order. Service providers will also work on a maintenance plan so that small repairs and service plans will work to keep the door in working order. These plans will then save the cost of repairs in the future because of the service they provide. Also, repair costs on parts will need to be tracked when the door is repaired to keep costs down.

Common Issues Affecting Cost

Unexpected Expenses: Repairs and Upgrades of High-Speed Doors

When businesses close their doors for the day, to some, that may mean the end of the day. But for some businesses, that may mean the beginning of the end; doors are a necessary aspect of business life. Once high-speed doors are installed with their related systems, businesses rely on them to be available at all times to control the environment and efficiently serve the business’s customers. However, costs related to repairs and or necessary enhancements are a reality every business needs to consider. Doors can break for a variety of reasons, such as a broken motor, a damaged panel, or a broken/defective sensor. Because so many things can break and potentially create a door expense, many businesses are running the risk of door-related costs, which can include business-disrupting malfunctions. What are the costs associated with doors?

Operating a business is expensive; however, there are associated costs that need to be expected, such as door-related costs. Operating a door is expensive, but it is necessary to control the environment and serve customers.

Nevertheless, the necessary costs related to high-speed doors can be mitigated. Businesses can take steps to reduce the related door costs, like implementing regular inspections to catch door problems before they escalate to become costly expenses. There are other ways to reduce costs associated with high-speed door repairs, such as partnering with a high-speed door service that is knowledgeable about the new doors, inspections for holes, and other things that can be inspected.

Troubleshooting Typical Problems

High-speed doors are important for seamless workflows, and while they are important, they are not flawless. Here are a few common problems and how to troubleshoot them.

Doors designed for high traffic won’t open or close properly if not maintained.

Potential problems: broken control panels, faults in the door, or problems with the sensors.

Solution: Ensure the control panel is operational to check for power issues. Many sensor issues are caused by dirt, so clean them, check for any obstructions, and adjust the alignment.

Doors Close Too Slowly

Potential Problems: Improper lubrication or worn-out motor components.

Solution: Examine the motor and fix or replace any components that are worn out. Lubricate any tracks or rollers that are in motion.

Loud Noises While Operating

Potential Problems: worn-out rollers or debris in the wrong places.

Solution: Remove any debris and fix the alignments of the tracks. Replace any broken rollers.

Doors Getting Stuck

Potential Problems: Malfunctioning software, damaged cables, or obstructions in the tracks.

Solution: Clear any tracks of obstruction. Look for any frayed cables and replace them. Reboot the software to bring the system back to managed functionality.

Frequent Sensor Malfunctions

Possible Causes: Sensors may be faulty or outdated, or there may be environmental concerns like dust or humidity.

Solution: Upgrade to premium, all-weather sensors. Clean sensors routinely and consider protective shielding to avoid damage from the elements.

Modern smart diagnostic systems and advanced safety sensors can correct frequent sensor malfunctions. Manufacturers now design sensors to withstand harsher use, but businesses still need to stay informed about the latest products to optimize high-speed door performance and extend service life.

Best Practices & Cost-Optimization Tips

How to Choose the Right High-Speed Door for Your Budget

Finding the best value high-speed door isn’t easy. Look at the door cycle frequency, environment, and the energy efficiency you require when selecting commercial doors. Insulated high-speed doors will save you energy, and doors with motion sensors and emergency breakaway systems will meet safety standards. These options can be found with some online research.

Finding a door that fits your budget is easier when comparing models and materials. PVC and fabric doors are cheaper and suitable for partitions that don’t get a lot of traffic. Aluminum and steel doors are better for high-traffic areas and offer more durability. See if your purchase of commercial doors qualifies for a government rebate to reduce costs. Speak with manufacturers and installers about discounts, warranties, and maintenance. These will give you a better idea of the long-term costs associated with your purchase.

Negotiation Tips with High-Speed Door Suppliers

Negotiating a Discount on Bulk Orders

If you’re placing an order for multiple high-speed doors, ask your supplier if any bulk discount options are available. Providers usually supply bulk order discounts, so it might be worth your time to ask to save some money.

Comparing Multiple Supplier Quotes

In order to get the best pricing, warranty options, and pricing on add-ons, obtain multiple supplier quotes. This information can be used to leverage better pricing and warranty options to get one supplier to match the price of another one.

Negotiating Maintenance and Warranty Terms

Having peace of mind that the doors will not need servicing, or that they will be unburdened by service fees, can be a good reason for a longer warranty and maintenance packages. Offering free maintenance with buy doors can reduce overall costs.

Negotiating Customization Fees

If any of the doors need to be custom-sized or modified, you may be able to get the supplier to remove the customization fees if you negotiate during the time of order. Showing them that you plan to do business with them again may improve your chances.

Negotiating Early Payment Discounts

There is a set of suppliers that will give price discounts due to early payment, or payment in full before the service has been provided. If early payment discounts are available, try to set the payment terms to favorable terms for the supplier.

Leading Brands and Product Comparisons

Top High-Speed Door Brands and Models: Features vs. Price

When looking into high-speed doors, a few major retailers come to mind first in terms of innovation, strength, and performance. Below is a summary of major retailers, their respective models, descriptions of their attributes, and a comparison of their pricing.

Rytec Spiral® High Speed Doors

Characteristics: Considered one of the leaders in the industry for construction and durability, Rytec Spiral doors utilize patented construction techniques that focus on diminishing operational noise while boosting efficiency. They are suited for instances that require an air-tight seal and a high frequency of use.

Pricing: Premium pricing is the case for these products.

Hormann High-Speed Doors

Characteristics: This brand is well known for high performance with a variety of operational speeds, and with construction that guarantees high-quality energy efficiency while incorporating insulation to aid in temperature sensitive situations. From an operational standpoint, the construction prioritizes efficiency coupled with its, proprietary crash-repair mechanism.

Pricing: From a commercial standpoint, this is an economically favorable option in the mid to high tier pricing category primarily targeted to the industrial sector.

Dynaco Rapid Roll Doors

Characteristics: Dynaco specializes in high-speed roll-up doors that are designed for safety, operational flexibility, and customization. These doors are wind-resistant and are operational in extreme indoor and outdoor temperatures.

Pricing: These doors are usually priced in the moderate range, except those designed for specific industry design requirements.

Albany High-Performance Doors

Characteristics: For high cycling speed operations, these doors are designed for high efficiency and are suited for environments such as cleanrooms, warehouses, and heavy industrial duty applications.

Price Range: High visibility pertaining to the price, coupled with the versatility and performance.

TNR Industrial Doors

Features: Built to endure heavy-duty industrial routines, TNR’s fast-operating doors enable optimal functionality for tough/everyday operational conditions. Most optimal for heavy user scenarios.

Price Range: Industrial-grade quality at competitive rates.

While selecting industrial routines for your operational high-speed doors, consider the touchpoint energy, operational efficiency, and the surrounding temperature. The right operational high-speed doors budget, along with the industrial operational routines, should strike the right balance.

SEPPES High-Speed Doors

SEPPES High-Speed Doors have been made for avant-garde, engineered, versatile high-speed doors operational for contemporary industrial sectors. Routine workflow management reinforced with reliability and durability to endure tough operational conditions and frequent use. The SEPPES doors technology, coupled with energy management, makes for an affordable industrial-grade quality high-speed doors without compromising on operational speed.

Price Range: Industrial-grade quality high-speed doors designed for high volume at affordable pricing.

While selecting SEPPES high-speed doors, determine your operational conditions as industrial temperature enclosures, antifreeze, and user ruggedness touch-points for your high-speed doors. This will ensure your doors at affordable pricing at the industrial grade with no compromise on quality.

User Reviews and Ratings

SEPPES high-speed doors are very dependable and cost-effective, and user reviews are very positive across the board. These doors are praised for their impressive endurance and continuous service in demanding environments. Their doors received multiple reviews raving about their service for Remarkable Usability Reviews. On Google and Trustpilot Reviews, SEPPES is appreciated for the impressive opening and closing service and for the productivity increase due to less servicing.

Users appreciate the closure and the energy-saving features. While sealed, energy costs are saved, and the internal temperature levels are controlled and maintained. Google reviews show SEPPES high-speed doors rated consistently anywhere from 4.5 to 5 stars. Many reviews appreciate SEPPES’ customer service and the ability to modify doors based on the specific user.

Some reviews suggest hiring a professional to handle the first service to ensure correct installation and setup. Beyond that, customers place strong trust in SEPPES for durable high-speed doors, which they can purchase from a reliable high-speed door provider at competitive prices.

Actionable Insights and Decision Guide

Cost Worksheet: Factors to Consider Before Buying

To identify whether high-speed doors are worth buying, there are some factors that need to be taken into account to make sure that you are making not just a functional, but also a financially smart decision. These include the following:

The Upfront Cost of the Product

Consider the door’s base cost, which will also include the materials, which may vary in speed, size, and other custom options.

Check several suppliers to know which of them will give you the most for your money.

The Cost of Installation

Determine whether the installation is covered in the cost of the door, or whether it is necessary to obtain the services of a professional.

There may also be some additional charges for elaborate installations or customizations.

How Much Maintenance and Repair Does the Door Need

Consider the additional costs that come with the door, such as downtime, emergency repairs, and annual inspections. These assessments help you avoid unexpected expenses related to warranties, replacement parts, and other covered items.

To cut costs, it is best to buy the door that will last the longest.

The Amount of Money the Speed Door Will Save You on Your Electric Bill

Due to high-speed doors, there is a significant reduction in the amount of air that is lost. As a result, there is a need for less conditioned air, which saves the company money.

High-speed doors with thermal insulation and configurable energy-saving features have the best performance in this area.

If the door is adding or Reducing Time to Your Workflow

Consider the speed and reliability of the doors.

If the doors are seamless in their operation, they will add time to your schedule. If they are anything less than that, the speed and reliability will reduce your productivity and add downtime in your operation.

Taking these factors into consideration can help you understand your total cost of ownership and choose a high-speed door solution that meets your operational and financial objectives.

Checklist for Choosing a High Speed Door

When looking into a high-speed door, there is more than one element to consider to fit your doors with operational needs. Below are actionable insights with a checklist of five considerations.

Speed of Operation

Think about how fast the door opens and closes. In most cases, doors that operate between 50 and 100 inches per second are good for high levels of traffic. The faster, the better, especially in relation to efficiency.

Durability and Material Quality

Doors can be made of different materials like reinforced PVC, aluminum, and others. The longer operational life of doors with more durable materials means a door for more demanding environments will be more dependable for longer.

Insulation and Energy Efficiency

Consider how well a door is insulated and how well it keeps heat in (or out). Energy costs can be minimized by 30% with high-speed doors having well-aligned seals.

Safety Features

Check to see that a door has all the components of a door with ‘safety measures’ such as a soft edge, sensors, and stops to patrol to injury zones and hinder passing doors.

Maintenance Requirements

Research how often a door will actually need to be serviced, and if parts of the needed repairs are available to purchase. Doors that have lower needs per unit of time for maintenance will lower your total operational costs over longer time spans.

Conclusion

Summary of Trends and Recommendations

The door industry has expanded radically over the years. Increasingly rapid doors are seen as an innovation because of the increase in operational workflow and efficiency, particularly in settings designed for high volume. They are also seen as a cost-saving measure because they conserve energy. Monitoring systems are being integrated with these doors and paired with IOT systems to provide remote monitoring. Simple systems with smart doors integrated provide maximum efficiency without downtime.

The operational cost of a business can be drastically reduced by using highly insulated, energy-efficient doors in controlled environments, particularly those designed for high traffic.

Using these doors improves a company’s energy efficiency and bottom line because manufacturers use sustainable, recyclable materials. When businesses pair the doors with IoT systems, they maximize operational efficiency and cost savings.

Encouragement to Use Expert Consultation

Choosing the right high-speed door is easier when you have someone to guide you. I would suggest talking to someone in order to find a solution that works best for you and helps achieve your operational, sustainable, and efficient goals. Having experts help you is the best way to make the right choice for your needs and your investment.

Frequently Asked Questions (FAQs)

What affects high-speed door cost?

Factors that can affect the cost of high-speed doors include size (per door), materials (fabric doors vs. steel doors), opening speed, insulation (thermal performance), wind load, and special applications. Additionally, basic safety features (photo eye), programmable controls, and different types of door openers, customization, and installation (new vs used) can drive up costs, especially for doors ideal for high-traffic areas. Heavy-duty options include cost-effective gearboxes and reinforced sections for forklift traffic at loading docks of high-traffic commercial buildings.

Are high speed roll up door prices higher than conventional doors?

Average high-speed roll-up doors cost more than standard doors and basic garage doors, and the primary reason for this is that high-speed roll-up doors have been engineered for higher volume traffic and need to open and close more frequently. They include additional features such as programmable controls and more robust materials/fabrics. Less frequently encountered high-speed doors can also be worth even more than the cost recommendations, especially for industrial and commercial applications. They provide excellent value by reducing the costs of energy and downtime, and also improving workflow.

What should be included in the installation to safeguard performance?

Some considerations come into play with professional installation services. There should be monitoring services that withstand any wind loads so that they do not break or become misaligned. Monitoring services should also be aligned so that the doors operate smoothly throughout the opening and closing. Additionally, photo eyes and safety edges should be integrated, and programmable settings or openers and gearboxes should be checked and verified. In loading dock or forklift areas, professionals should ensure the door is independently tested and that it meets thermal performance needs. The door should also be configured with expectations on traffic to minimize maintenance and prolong the life of the door.

Which is better for energy bills and contaminant control?

There are many different commercial overhead door designs. Some sectional doors provide good insulation and thermal performance, while high-speed fabric doors minimize air exchange to control contaminants and reduce energy bills in high-traffic areas. The insulation value, how fast the opening speeds are, and the frequency of the opening and closing of the doors. In operations that are sensitive to contaminants, ideally, you would want a fast, high-performing rubber or fabric door that closes quickly.

What standard safety features come with high-speed doors?

Standard safety features typically include photo eye sensors, reversing mechanisms, edge sensors, and programmable limits. High-speed doors also include manual override for power loss (220 single-phase or three-phase considerations), warning lights or audible alarms, and emergency breakaway sections to safeguard personnel and equipment in busy commercial buildings.

How much do doors need servicing, and can servicing save money?

The maintenance of rubber and fabric doors includes checks of seals, tracks, tensioning systems, motors, and gearboxes, and the testing of limits and photo eyes. Regular maintenance is critical for avoiding downtime and expensive repair costs. Maintenance is especially important for fabric and rubber doors installed on heavy-duty, high-volume applications where the doors cycle multiple times per day to ensure optimal closing speeds.

Are there options for special applications like high wind loads or forklift traffic?

Commercial high-performance rolling doors and heavy-duty fabric doors are indeed designed to endure high wind loads, forklift impact, and heavy-duty usage. Options vary for sectional doors reinforced with fabric, impactable reinforcements, stronger gearboxes, and big door models that are certified for loading dock usage. The additions of these features raise the price but will lower the expensive costs associated with repairs and replacement over the years.

How do opening speeds and door design affect workflow?

Doors also lower the energy loss and the entrance of contaminants when they are opened and closed programmed to fit the traffic patterns. Waiting times for vehicles and forklifts are also reduced with faster cycle times on high-speed rolling doors. The right choice is important when picking a door model, whether a high-speed fabric door or an insulated sectional. The right choice per door model is critical to operational efficiency and total ownership cost.

Should I buy new or used to get the best value?

New doors come with the latest safety features, thermal performance, and warranties, which can be important for industrial or commercial use. If used doors have been inspected for part wear, validated for key components like the opener and gearbox, and meet safety standards, they can be worth it. To assess the best value for your commercial building, consider per-door lifecycle costs, including energy usage, maintenance, downtime, and other related costs.

Reference Sources

- Low Cost Interior Duct Systems for High Performance Homes in Hot Climates – Published by the Florida Solar Energy Center, this document discusses cost-effective systems, including door mechanisms.

- Development in Energy Harvesting System Using Escalator & Four Way Door Mechanism – An academic paper exploring energy-efficient door mechanisms and their cost implications.

- Development of a Low Cost Automated Sliding Door – This paper focuses on the development of cost-effective automated sliding and high-speed doors.

- Garage Door Security System – A project from California Polytechnic State University discussing cost-effective door security systems.

- Less-Than-Lethal Quick Deploy Inflatable Hall/Door Barrier: VISTA Feasibility Study – A study from the U.S. Department of Energy’s OSTI database, exploring innovative door barrier systems.