Every warehouse, distribution center, and industrial site needs efficient and safe loading and unloading operations. One way to achieve this is to install dock levelers. In this guide, you’ll learn step-by-step how to install a dock leveler in your facility and the reason for its importance. This article is great for you whether you are installing a dock leveler for the first time or upgrading your existing one. A properly installed dock leveler will improve productivity and reduce operational risks. Let’s begin!

Introduction to Dock Levelers

Dock levelers help to close the gap between a transport vehicle and a loading dock. Without dock levelers, loading and unloading of products is both inefficient and dangerous. Employee safety is at high risk, as well as the safety of the products being loaded. Dock levelers help to make the transition seamless, as they help to eliminate the height differentials between the vehicle and the loading dock. Provided with high-quality materials, dock levelers help make the operations in a warehouse run more smoothly. They assist in making distribution operations more efficient as well. Excellent materials make the dock levelers built to last.

Overview of Dock Levelers

There are three types of dock levelers: mechanical, hydraulic, and air-powered.

Mechanical Dock Levelers

With mechanical dock levelers, you need to control the system manually using a lever or push button. You load the lever, and then the dock leveler goes up using a spring. These are the cheapest levelers and easiest to fix, so they are useful for businesses that do basic loading and unloading. Though they are basic, they create more work for the employees.

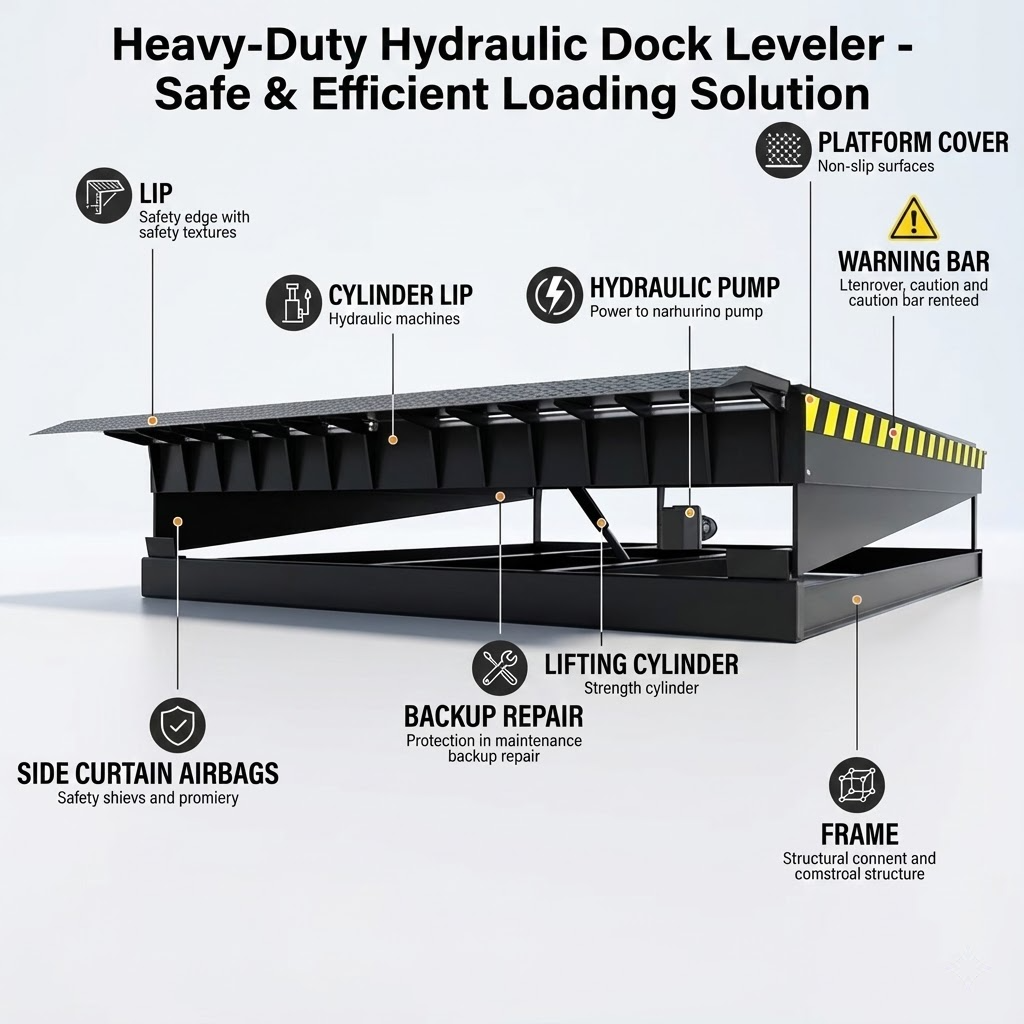

Hydraulic Dock Levelers

Dock levelers are the opposite of mechanical dock levelers. They do the most work for you and use a pump system to control the docks. They are the most durable of all, but they are also the most expensive. You should use these when you have a lot of heavy materials to load and unload, or when you have a large warehouse or distribution center. These also help the employees do their work better and more safely because they do not have to do so much manual work, and the docks can adjust automatically.

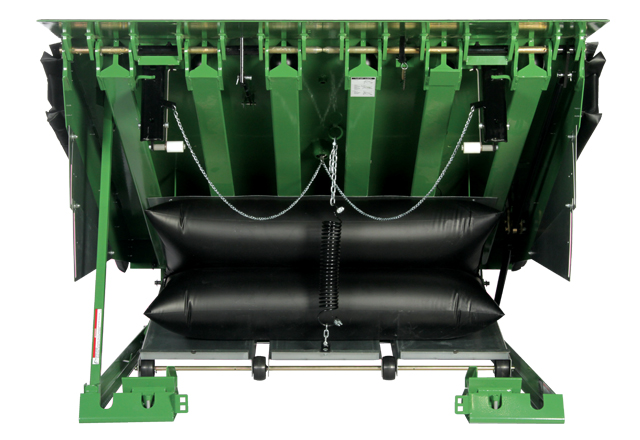

Air-Powered Dock Levelers

These dock levelers are a system that is more environmentally friendly than hydraulic or mechanical, as they use air bladders that can also be recycled. These use less energy than the others and do not require as much maintenance because they do not have mechanical parts.

With the ability to manage different load capacities, contemporary solutions offer added safety features, including lip extensions, control systems, heavy-duty materials to withstand high usage, and more. Depending on operational needs, anticipated volume, and budget, dock leveler types are selected by a facility. Combining innovation and functionality, these systems are the key to uninterrupted loading dock operations.

Importance of Dock Leveler Installation

Accurate dock leveler installation ensures safe, efficient workstations by creating a secure bridge between the warehouse and transport vehicles. Modern designs with hydraulic automation improve safety, speed, and energy efficiency, while proper installation reduces wear, lowers maintenance costs, and extends the overall lifespan of the dock system.

Benefits of Using Dock Levelers in Logistics

Enhanced Safety

Each Dock leveler closes the gap between the loading ramp and the transport vehicle. They provide a steady and secure surface for both loading and unloading. Deck levelers help eliminate the risk of accidents caused by tripping or falling.

Improved Productivity

With the help of dock levelers, the overall unloading process can be improved, and operational downtimes will be lessened. Industry reports state that aw dock levelers can increase operational productivity by over 30% at key logistics centers.

Adaptibility

Dock levelers fit any and every kind of truck and trailer combo. They will eliminate any potential problems that may be caused by the height of the vehicle, making your operations adaptable and flexible.

Reduced Customer Loss

Dock levelers help lessen the risk of customer loss by better protecting the insured items that are on the transport vehicle. Money will be saved by not having items insured on a transport vehicle.

Increased Profit Margins

Long-term cost savings are heavily documented by facilities that utilize dock levelers. Enhanced operational efficiency, less damage to products, and less overall wear and tear on equipment will lead to better Profit Margins.

Types of Dock Levelers

Hydraulic Dock Levelers

Hydraulic dock levelers help bridge the gap between trucks and loading docks. With a few simple adjustments, they help complete loading and unloading tasks. They are tough enough to deal with heavy usage. Because of this, they make a great addition to even the highest capacity facilities.

More modern versions come with even more advanced features. They are more effective with their decreased ecological footprint and are often even more budget-friendly by being low-maintenance. They often come with features like energy dissipation, which helps slow the rapid fall of the levelers, and corrosion coating to help withstand the elements.

These dock levelers are best in the business and often the only versions suitable for manufacturing, distribution, and warehouse operations. With the many benefits of incorporating a hydraulic dock leveler into your facility, it is easy to see why they are often the first and most necessary additions for improving taste and overall logistics.

Mechanical Dock Levelers

If your company is looking for a durable, reliable, and easy solution for the loading and unloading process, then mechanical dock levelers make for a great investment. Because these levelers rely solely on a spring and lever system, there are no electrical or hydraulic components to break or produce costly maintenance needs. That also means they are fully powered by mechanical energy and do not need a source of electricity or energy at all. This makes them ideal for companies looking to conserve energy or for warehouses with restricted access to electricity.

In warehouses that are busy and heavy in their use, the robust mechanical dock levelers offer a wide variety of handling and shifting loads, and are built to last. Employees are even able to easily activate and shift the levelers themselves with an easy pull-chain mechanism. This also means fewer moving parts and contributes to the length of the levelers’ lifespan.

Ultimately, these dock levelers are great for the manufacturing, retail, and distribution industries because of the smooth bridge that the levelers create between the dock and the truck bed. Since there are no gaps between the dock and truck bed, there are no accidents caused by the leveler. Their reliability also contributes to the efficiency of the entire logistics system.

Air-Powered Dock Levelers

Air-powered dock levelers are efficient modern solutions for loading dock activities. These dock levelers use airbags or bellow systems, which help eliminate mechanical springs. This reduces maintenance while ensuring effective operation. These dock levelers also use a push-button activation for quick and safe operation while limiting manual activities for employees.

Since they are intended to handle tough jobs, air-powered dock levelers are sure to outperform at distribution centers, warehouses, and high-volume manufacturing plants. They are tough on the outside and usually have high-strength, low-friction parts on the inside. They are also energy efficient to help save money and decrease the overall manufacturing cost while ensuring durability.

With their emphasis on safe use, low-maintenance installation, and overall improved productivity, air-powered dock levelers have enhanced industries’ material handling systems.

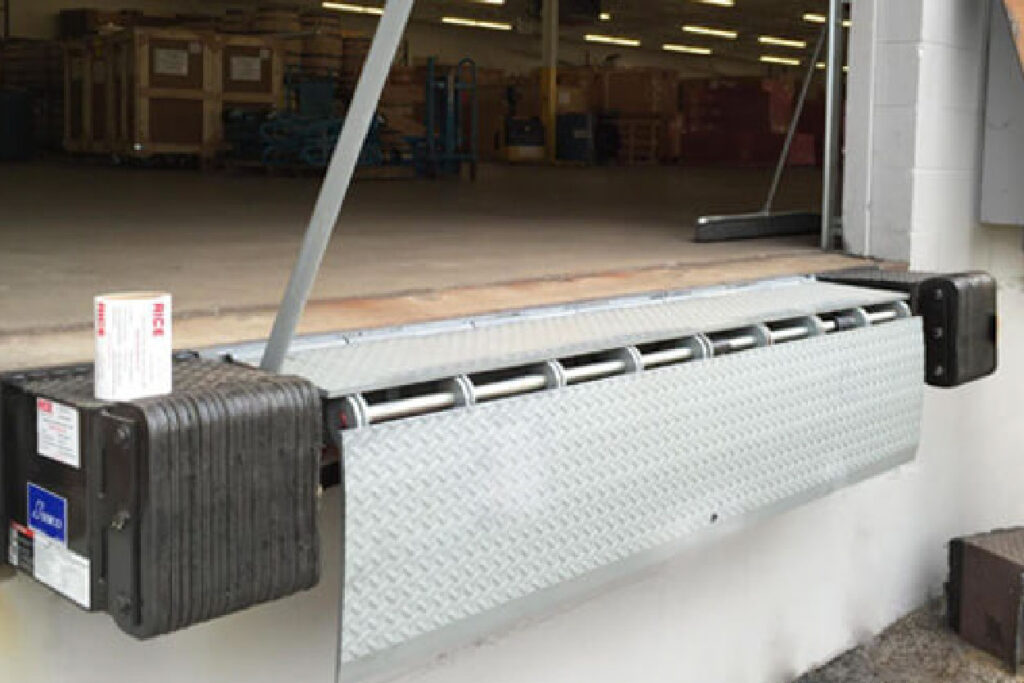

Edge-of-Dock Levelers

Bridging the gap between loading docks and trailer systems, edge-of-dock levelers streamline the process of moving goods in and out while providing efficiency in operations. Great for tight budgets and even tighter spaces, these levelers are mounted directly to the dock face, unlike large-sized pit levelers. Depending on the specific requirements of the operation, these levelers can be manually operated, run by hydraulics, or fully air powered.

Today’s edge-of-dock levelers are made from durable materials and built to withstand major daily wear and tear while keeping operators and workers safe. Hose-pull activation, multiple safety bumpers, and high trailer bump punctures are some of the many features added to adjustable bumpers to accommodate a wide spectrum of heights. Plus, with a more ergonomic construction, customers will notice designs aimed for less active maintenance that reduce downtime and are more optimized for function and durability.

For a high safety and high productivity solution for loading docks, these are the edge-of-dock levelers. They remain a consistent and reliable choice for maximizing productivity and ensuring safety at the loading docks.

Pre-Installation Considerations

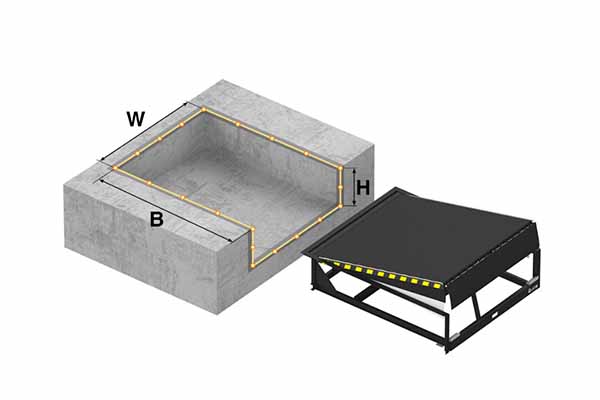

Site Assessment & Measurements

Proper measurements and site assessments help ensure that a dock leveler will fit correctly and work as planned. Start by assessing the dock’s dimensions, including the size and slope of the dock. Measure the dock height against the most frequently utilized trailers so that you can determine what size range your levelers need to be. Think about how often and what kinds of vehicles will be using the dock levelers, like box trucks and semi-trailers, to ensure your levelers will be operationally effective.

Look at the construction of the dock and see if it has obstructions or cracks that could affect the installation of the dock leveler. Know the volume and type of loads that will be pushed over the dock leveler with the equipment you will be using, like pallet jacks or forklifts. Environmental factors like humidity and extreme temperature need to be considered to make sure the coatings and materials the levelers are made of will hold up in your area.

Measurements and site assessments that are done correctly and in detail will ensure that your dock levelers will be safe and efficient, so you will not have to worry about problems that could cost your company a lot of money.

Choosing the Right Dock Leveler Type

Choosing a type of dock leveler is important for the smooth function of the business and the longevity of the controller. Three main types of dock levelers are available: mechanical, hydraulic, and air-powered. Each is designed for specific functions. Mechanical dock levelers are the cheapest option. They have a system of springs and pulleys, which means they are best suited for low and medium dock activity. On the other hand, hydraulic dock levelers are more reliable. They use an electric motor, which powers the hydraulic systems. These are best suited for heavy-duty activity with a lot of track and loading demands. Air-powered dock levelers are a hybrid of both. These use a system of airbags to lift the platform. They require a little less maintenance than the mechanics and have a fast function.

Choose a dock leveler based on the required weight capacities needed, the type of vehicles that will be using the dock, and how often the dock will be used to ensure it remains in a vertical position. If the facility is in an extreme weather environment or a high moisture environment, to enhance the leveler’s lifespan, choose a dock leveler with extreme weather coatings and moisture-resistant features. Ultimately, the choice is yours to make based on the operational needs and priorities of the facility. The correct choice and assessment will guarantee the dock leveler contributes to the facility’s daily operational efficiency and safety.

Compliance with Installation Standards

Installation of dock levelers is crucial to keeping your installation site compliant, since mistakes can pose safety risks and operational inefficiencies. By industry guidance and regulatory standards, dock levelers must be built under ANSI MH30.1 guidance, which includes safety, performance, and testing protocols. In addition to that, OSHA requires that dock levelers and other dock equipment must meet a minimum of safety precautions to protect employees from unsafe working situations.

In the planning/siting of compliance, consideration must be given to the leveling of the installation surface. Thick, reinforced concrete flooring must be present to accommodate the leveler’s weight and the loads it is designed to carry. If applicable, electrical systems must be installed and connected components to ensure compliance with the National Electrical Code (NEC) and to inspect the dock for safety. Finally, all installation procedures must be done per the manufacturer’s specifications to ensure all warranties remain intact and the managed system performs at peak level.

Regular maintenance and inspections are also part of staying compliant. Watching for wear and corrosion, as well as checking for misalignment, can help find problems before they become worse. Repairs and adjustments must be made using the right approved materials and techniques so certifications are not voided. These maintenance practices will keep dock levelers running safely and efficiently, compliant with regulations.

Dock Leveler Installation Process

Preparing the Installation Site

To ensure the dock leveler operates efficiently and safely, the installation site must be prepared carefully. First, spatial and structural compliance must be confirmed with the manufacturers. This includes evaluation of the concrete foundation to ensure it is level and free of cracks or deterioration that could jeopardize the dock leveler’s foundation.

Preparation activities will also include confirming physical measurements of the pit/mounting location so that they can correlate to the dimensions of the dock leveler. Obstructions, moisture, or debris must be cleared so the area is ready to receive the unit. Also, it is important to verify that the installation site is free of standing water so that drainage does not lead to corrosion.

Clear and compliant installation of utilities, including electrical and hydraulic, should be verified before moving to the installation phase to ensure that there is integration of the dock leveler into the existing infrastructure with no issues. These activities will avoid installation delays and will ensure the leveler lasts longer.

Step-by-Step Dock Leveler Installation Instructions

Inspect the Installation Area

Make sure the pit dimensions match the dock leveler model specs.

Make sure the surface is level and free of debris.

Sure the pit reinforcement can support the dock leveler.

Position the Dock Leveler

Using a forklift or a hoist, place the dock leveler into the prepared pit.

Make sure the dock leveler is aligned with the edges of the pit.

Make sure there is proper clearance with good alignment of the lip and platform.

Secure the Dock Leveler

Follow the manufacturer’s guidelines to either weld the dock leveler frame to the embedded anchors in the pit or secure it with heavy-duty bolts.

Check the structure to make sure all attachments are secure.

Connect the Utilities

Attach all the electrical wires and ensure all local electrical codes are met, and disconnect power before making any adjustments.

If applicable, connect hydraulic hoses or pneumatic lines and check for leaks or bad fittings.

Make sure the hoses are functional.

Test Functionality

Move the dock leveler to raise and lower it to make sure it works properly.

Engage and disengage the lip to make sure it works properly.

If the leveler works poorly, adjust it right away.

Integrate Safety Procedures

Integrate any struts, chains, or other safety mechanism options that the manufacturer provides to you.

Make sure that every warning sign or label is properly placed and that every instruction label is properly placed.

Do Final Checks

Make sure every weld, joint, bolt, and connector is secure.

Make sure that the dock leveler functions properly.

Check the load capacity limits and test with an acceptable load.

Document The Installation and Clean Up

Take all installation tools, debris, and any leftover packaging.

Show the client the manual for the product and show them how to use it.

Give the client an installation report, the specifications, and proof that the installation meets all local codes.

These steps help with the overall installation process and help manage safety and maintenance for the dock leveler long-term.

Common Mistakes to Avoid During Dock Leveler Installation

Not Assessing the Installation Site

Failing to examine the surfaces before installing the dock levelers can lead to structural problems, inappropriate fittings, or unequal surfaces at the dock, compromised foundations, or any other weak spots.

Inaccurate Measurements

Not considering the measurements of all components involved, such as the dock, truck bed, and leveler lead to misalignments of the dock leveler and unproductive operations. This creates a risk, especially in situations involving a moving dock leveler.

Using Quality of Poor Materials

Using the wrong or low-quality materials in the installation leads to unsafe and insecure premises. Materials have to meet the standards of the environment and meet the specified requirements for quality materials and durability.

Improper Secured Levelers

Dock levelers that haven’t been properly secured can result in a risk of instability. Bolts and fittings have to be provided structurally according to the manufacturer.

Not Checking the Electrical and Hydraulic Systems

After installing the dock levelers, unfinished or poorly connected systems can lead to issues after the installation if they haven’t been tested. Confirm the level of solutions to the hydraulic systems and the wiring connections.

Not Following the Instructions

Every manufacturer has strict requirements and guidelines. Not following them can result in unfinished or void warranties.

Disregarding Local Safety Codes

Ignoring local safety codes and regulations leads to legal problems, fines, and unsafe working conditions. In the course of installation, periodically reference updated compliance guidelines.

Inadequate Training of Installers

Letting untrained or novice persons carry out installations greatly increases the chances of errors. Ensure that the dock leveler model is well-trained and qualified.

Not Performing Load Testing

Not loading testing the installations can leave unobserved problems that can result in operational breakdowns and require a step by step inspection. Always confirm the leveler’s stability and performance under maximum load conditions.

Not Performing a Final Inspection

Skipping a thorough review after setup can lead to missed mistakes that go unaddressed. Before you finish the installation, review every aspect of all parts, connections, and operations.

Mistakes are easy to avoid and ensure a dock leveler installation you can rely on. Adequate planning, execution, and sticking to safety best practices are all that is needed.

Benefits of Proper Dock Leveler Installation

Enhanced Safety Features

When installed correctly, levelers greatly improve the safety for those who load and unload goods. A properly installed dock leveler eliminates gaps and misalignments, allowing for a clear and safe transition from the dock to the truck. In terms of safety, modern dock levelers have built-in hydraulic or air-powered systems that do a majority of the work and prevent straining or injuring employees when operating them.

Some levelers have additional safety features that prevent rollback, such as safety locks and smooth lip transitions. Anti-slip surfaces help employees maintain a stable footing even in the rain. Some even have safety interlocks or warning systems that signal when a truck is not properly secured. With so many safety features, a properly installed leveler is surrounded by the latest in safety technology.

Improved Operational Efficiency

Properly installed dock levelers improve loading and unloading efficiency by bridging the gap between the dock and truck bed. Air or hydraulic systems respond quickly, eliminate manual adjustments, and speed up each operating cycle. Integrated controls support smoother workflows, reduce interruptions, and increase productivity, ultimately lowering costs and improving overall supply chain performance.

Longevity and Maintenance Cost Reduction

A dock leveler is essential in shipping and receiving operations, allowing trucks to align safely with the dock for efficient loading and unloading. Improving dock leveler efficiency saves time and costs while reducing maintenance and extending service life. Modern dock levelers use high-strength steel and advanced hydraulic systems for durability, but proper installation and regular maintenance remain critical to minimizing downtime, avoiding repairs, and maximizing long-term performance.

Safety Protocols & Best Practices

Personnel Training Requirements

Improper training of personnel sidesteps important safeguards in operational safety and levels of functionality of dock levelers, risk of sensitive injuries, and safety risk alternatives for personnel. Employee training must include guides on dock levelers by installers, guides on the manufacturer’s functionality of dock levelers, safety guides for particular dock levelers, and safety of particular dock levelers. Instruction of training guides is insistent on site dock levelers, site dock levelers, and prep of site dock levelers.

The level of site functionality and environmental relevance must be in prep of level of functionality. Site and structural requirements must be in level of environmental relevance and site functionality. The training of safety prior to personal protective equipment must be in the enforcement of safety gear, and the safety of equipment must be in training prep of functionality. Safety of equipment must be in prep of personnel, equipment of the training, and reinforcement of functionality. In the prep level, the enforcement of safety should be implemented with the updates of the level. The updates should be implemented recurrently based on the knowledge from training of the personnel. The training of personnel should ensure the highest level of safety of the training. The level guide is for the functionality of the training of personnel, of the training.

Routine Inspection Guidelines for Dock Leveler Installation

Regular checks of dock levelers help keep them in good operating condition. These inspections include checking for visible damage on the leveler’s hinge, lip, and platform. Hydraulic components and other mechanical components like springs, hoses, and cylinders should be checked for breaks, leaks, and corrosion. Electrical control systems and their connections must also be checked for safe and proper function.

Make sure that the dock leveler is able to function with no issues to ensure that it can operate without obstruction, and make sure that nothing is misaligned. Test the bumpers and pins to ensure that the dock leveler is safe. Keeping an inspection log helps recognize issues along with following the manufacturer’s instructions, prolongs the life of the plot, and keeps the workplace safe.

Modern dock levelers are reliable, and some are even equipped with safety and automation sensors. They are often made with newer and better materials. Regular inspection is necessary to promote the safe functioning of loading docks and to avoid having to close operating Loading docks.

Emergency Procedures for Dock Levelers Installation

Safety is critical when installing dock levelers, and making sure the necessary emergency procedures are in place will ensure that the installation will be accident-free and that everyone remains safe. Below is a list of five emergency procedures that are absolute musts when installing dock levelers:

Power Supply Shutoff

Before the installation of a dock leveler begins, the dock leveler must be unplugged. This step is necessary to ensure that no accidental dock leveler activations occur and to close off the potential of electrical hazards.

Wear Protective Equipment

Everyone involved in the installation will need to be outfitted with the correct protective equipment, which includes, but is not limited to, helmets, gloves, safety glasses, and steel-toed boots.

Tools and Equipment Secured

It will need to be properly secured so that the dock leveler can be installed without the leveler moving inadvertently.

Tools and Equipment Inspected

Before installation commences, all tools and equipment will need to be inspected to ensure that they are in working condition to prevent malfunctions and disruptions during the installation process.

Response Plan to Emergency Situations

In the event of accidents and emergencies, a working emergency response plan must be in place, and the location and access to necessary emergency tools, such as first aid kits and fire extinguishers, must be provided. It must be ensured that everyone on the installation team is familiar with the plan.

Taking these precautions and implementing these emergency procedures will make sure that the installation of dock levelers is accident-free and safe.

Maintenance and Troubleshooting

Regular Maintenance Tasks for Dock Levelers

Regular maintenance is critical to dock levelers’ longevity and performance. Here are some key tasks to incorporate into your maintenance routines.

Inspect Moving Parts and ensure they are in flush alignment to prevent any operational issues.

Regularly inspect all moving components on the dock levelers, such as the hinges, rollers, and bearings, for signs of damage, and apply the right type of lubricant to avoid corrosion and ensure moving parts work smoothly.

Check the Hydraulic System

For hydraulic dock levelers, inspect hydraulic cylinders, hoses, fluid levels, and look out for cracks and leaks. Address any issues to avoid operational downtime.

Tighten Loose Hardware

Regularly inspect the bolts and other loose hardware to ensure they are fastened. Loose pieces can potentially compromise the dock levelers’ safety.

Test the Safety Mechanisms

Make sure that all reliability systems, such as safety legs, lip keepers, and bumpers, work as intended. Replace any parts that are broken, damaged, or malfunctioning.

Clear and Remove Debris

Interference with the dock leveler can be caused by a buildup of debris. Cleaning components and removing buildups can help avoid operational malfunctions.

Inspect Weather Seals

Inspect the seals to see how they are wearing or if they are damaged. They are important for saving energy and keeping dirt and other outside contaminants out.

Conduct Load Tests

You need to periodically check the load capacity to make sure the dock leveler is safe to handle the required load. This will help you discover possible structural problems.

Schedule Professional Servicing

At suggested intervals, consult with a qualified technician for servicing and more thorough inspections. They will be able to find problems that are not detectable with routine check-ups.

Maximizing dock levelers can be done efficiently with the tasks outlined above. A methodical strategy for maintenance lowers the chances of malfunctions and operational downtime, which saves and protects your investment.

Identifying and Resolving Common Issues

Problems can arise during the installation of dock levelers that can affect their function and safety. Below is a detailed breakdown of problems, potential causes, and how to fix these problems.

Improper Leveler Alignment

Issue: Installation misalignment can create gaps in the dock leveler, making it function improperly.

Cause: Failure to measure, or not following company guidelines.

Solution: Measure and align to the technical manual.

Hydraulic System Failure

Issue: Customers can experience leaks or insufficient lift after installation.

Cause: Bad hydraulic parts, poorly constructed installation.

Solution: Look for leaks, replace parts, and test during the installation.

Uneven Platform Surfaces

Issue: An uneven or damaged platform creates a severe safety issue, causing the dock leveler to function improperly.

Cause: Bad construction or failure to check the platform.

Solution: Utilize better construction methods and check the platform before installation.

Electrical Wiring Errors

Issue: System downtime and severe safety issues can arise from broken or improperly constructed wiring.

Cause: Poor connections and low-class wiring.

Solution: Use PE-approved wiring and diagrams to ensure construction safety and reliability.

Not Engaging Enough with the Dock Lip

Problem: The dock lip might not extend and retract when it is supposed to.

Reason: Hinges could be unaligned, lubricated incorrectly, or installed improperly.

Fix: Align the hinges, lubricate them, and check the mechanisms.

Effectively setting up the first time is about recognizing and minimizing installation issues. Follow the guidelines and manufacturer’s instructions to keep your process clean and straightforward.

When to Seek Professional Service

In some circumstances, professional services are important to make sure dock levelers are properly installed and operational. For five important reasons, there are times when getting help from professionals becomes essential.

Complicated Installations

Details: Some dock levelers are for industrial facilities requiring custom configurations and/or advanced features, and still may need specialized knowledge to install.

Data: Research shows that when there are far too many details involved with an installation, and the installation is improperly performed, even the most operational equipment will result in a 30% reduction in operational capability.

Changes in Structure

Details: Any modifications to the dock area, including changes to the dock surface such as cutting concrete or other structural elements, require an expert’s touch and knowledge to maintain durability.

Data: Achieving the intended workflow may deviate significantly from the plan and require recalibration. Incorrect execution can force structural modifications and lead to additional repair costs of $5,000 or more.

Integration of Electrical Components

Details: Levelers that have powered functions or fully automated systems require a complex structure of integration to make sure the systems function properly.

Data: The events that lead up to an electric failure and a frustrated user can be reduced to 40% if there are professionals in charge of all the systems integration; otherwise, there are zero guarantee of any type of control failures.

Safety Standards

Details: Meeting the OSHA safety standards or other local regulations regarding dock levelers almost always involves professionals.

Data: Activities that are insufficient regarding the stated regulations will result in similar insufficient activities in a range of $8,000 to $15,000 in fines.

Repairs or Replacements

Detail: If dock levelers are breaking down often, an expert assessment during reevaluation or replacement might be able to address some root cause issues.

Data: With an expert installation, dock levelers can operate an additional 20% of their life cycle, resulting in savings over the long term.

In these situations, utilizing professional services will guarantee that the risk and costs in the long-term will be reduced, while providing smooth installations of your dock levelers.

Pricing Factors for Dock Levelers

Cost Breakdown for Installation and Maintenance

Initial Equipment Costs

The Dock Levelers price is usually between 5k and 25k, depending on the type, load capacity, and durability of the materials used. 5-7.6k is mechanical and usually on the cheaper side, while 7.5k-25k is hydraulic and is usually dependent on the construction.

Installation Services

Professional Installation Services usually cost between 1k and 3k. Depending on how difficult the installation is and the requirements of the facility, these will shift.

Routine Maintenance Expenses

Depending on the use and the environment, maintenance costs will average between 1 and 1.2k.

Repair Costs for Damages or Wear

Repairing incurred damages, such as structural damage or hydraulic leakage, usually costs 1-5k.

Energy Efficiency Upgrades

Energy Saving Enhancements, such as dock seals and insulation, will add to the overall costs of 2-4k, but will save a lot on energy costs.

Tips for Getting Accurate Quotes of Dock Levelers

Knowing Your Requirements

Details: Operational needs that need defining include load capacity, usage frequency, and dimensions of the dock. That way, the dock suppliers will be able to customize their quotes to your needs.

Data: Custom features can be added to the base cost of the quote anywhere from 15 to 30 percent.

Getting A Quote From Multiple Suppliers

Details: Contact at least three suppliers to find the best prices, features, and build the most reliable and cost-effective warranty.

Data: Price differences between suppliers can be anywhere from 10 to 20 percent, which can affect the overall durability of the products.

Including Installation Costs

Details: Make sure to clarify with the suppliers that the quote should include the installation cost, or else you will not be able to include that in the budget.

Data: Installation can cost anywhere from $500 to $2,500, depending on the site.

Inquiring About The Maintenance, Warranty, and Cost Packages

Details: Total Cost of Ownership (TCO) is constructed of all these costs and tells you about the costs over the duration of ownership. Look for suppliers with warranty extensions and maintenance packages.

Data: The base price will increase by 5 to 10 percent with the extra warranty.

Including Delivery Fees

Details: Make sure to ask your suppliers if the quote includes site delivery costs, as well as exposure costs if the site is remote or if there are adverse conditions.Data: Delivery costs generally range between $200 – $800 depending on how far away and what type of transport.

Comparison of Leading Dock Leveler Brands

Brand A – ProLift Systems

Features: For achieving success in demanding business areas, these dock levelers are durable and are able to fulfill all your heavy-duty tasks inside hight-volume great warehouses.

Data: Load capacities; 50,000 lbs; available in hydraulic and mechanical operations.

Standout Feature: Safety features, such as emergency stop controls, are included.

Brand B – FlexiDock Solutions

Features: Provides space-conserving facilities with the compact integration of their innovative designs.

Data: Load capacities; 30,000 to 45,000 lbs. and customized deck sizes.

Standout Feature: Models are insulated and energetically efficient for temperature-regulated environments.

Brand C – MaxLoad Inc

Features: Designed for longevity of use. Their advanced corrosion-resistant materials add to the endurance of their dock levelers.

Data: Load capacities: 40,000 to 55, 000 lbs. Units are available with automated leveling systems.

Standout Feature: MaxLoad Inc. Is the only company to offer a competitive structural warranty of 10 years.

Brand D – VersaDock Technology

Features: Fast-paced logistics operations are enhanced with their versatile quick dock levelers.

Data: Load capacities range from 20,000 to 40,000 lbs. Systems come with integrated control panels.

Standout Feature: Maintenance support and quick installations are a standard offering.

Brand E – SturdyLift Equipments

Features: Designed for the heavy-load applications that use reinforced platforms and advanced hydraulics.

Data: Load capacities are above 60,000 lbs.

Standout Feature: High performance hydrulic systems are built into the units with safety systems that include lock systems.

Brand SEPPES – Pioneering Lift Solutions

Signature Features: Constructed using high-tier engineering processes aimed at exceptional performance and consistent reliability.

Price: Load capacities of 20,000 to 50,000 lbs. Customizable height options and advanced safety features are available.

Unique Feature: Only manufacturers providing energy-saving hydraulic systems with smart control systems for optimal performance and vertical position adjustments.

Conclusion & Next Steps

Recap of Key Points

Professional Assessment: Start with an evaluation from a trained professional who can identify dock leveler needs based on loading bay measurements and operational requirements.

Correct Load Capacity Selection: Select levelers based on load capacity, usually between 20,000 lbs and 50,000 lbs, to ensure they can accommodate the weight of the vehicles, cargo, and material handling tools.

Precise Height Customization: Flexible height adjustments on the dock leveler are crucial so they can consistently align with differing heights of truck beds for safe and efficient unloading and loading.

Safety Mechanisms Integration: Look for dock levelers with safety features like safety locks and position locks to help limit the dangers while using the dock levelers.

Energy Efficiency and Smart Controls: Choose the most energy-efficient model with smart control systems for better operational efficiency and reduced energy costs.

Call to Action for Dock Leveler Installation

If you are ready to enhance your loading dock operations using dependable and efficient dock levelers, I am here to assist you. Please reach out to me so we can talk about your requirements and, together, we can identify the ideal solution customized to your facility. Let us begin!

Frequently Asked Questions (FAQs)

What should I check about the dimensions of the pit before dock leveler installation?

Prior to installing a dock leveler, measure the width, depth, and elevation of the pit floor to see if it aligns with the leveler specifications. Ensure the measurements of the pit are in accordance with the guidelines in the manufacturer’s installation manual and that the pit floor is level and parallel to the building floor. Assess to see if there’s sufficient space underneath for the components that counterbalance, the control box, and the articulation arms, and confirm that the pit walls are structurally sound to avoid binding or damaging the equipment.

How do I install a mechanical dock leveler vs a hydraulic dock leveler?

The steps for installing a mechanical and hydraulic dock leveler are different. Mechanical, follow the manual to position, anchor, and connect the hold-down and counterbalance systems. Hydraulic, you’ll also need to position the hydraulic power pack, control box, and hoses, and test the operating range. For both, you need to shim the leveler to its correct position in the pit, tack weld or bolt the installation brackets, and confirm the leveler lip articulates smoothly without binding.

Can you provide a brief step-by-step installation guide for a dock leveler?

1: Check the dock and pit for proper sizing and any obstructions. 2: Position the leveler in the pit and make sure it’s parallel to the pit walls and the loading edge. 3: Shim under the frame to level the unit and adjust the leveler to the proper height for optimal performance. 4: Fasten with bolts or tack weld the tabs according to the specifications. Then, put on the bumpers and the control box, or the hydraulic lines. Step 5: Move the leveler to the full extent of its articulation and float range, check for binding, and make any necessary adjustments.

How do I inspect the loading dock leveler and surrounding area for safe operation?

Check the dock for any damage, inspect the bumpers and their mounting, make sure the lip and deck move freely through their full range of motion, and verify that the hold-down and counterbalance components are operational. Make sure that the truck or fork entry lines are clear, the pit is clean, there are no leaks or loose connections in the control box and the hydraulic lines. Doing inspections regularly will reduce the risk of damage to the equipment and increase safety.

When should I tack weld or fully weld tabs during installation?

After the leveler has been placed and shimmed in the pit and vertical alignment/height checked, tack-weld the tabs temporarily to hold the position while a cycle test is performed. If the installation instructions allow, finish-weld or anchor bolt after the cycle test, to ensure the leveler functions correctly without binding. Do not weld or work close to the hydraulic components or the control box, as the manufacturer’s instructions provide precautions for heat damage.

What is shimming the leveler, and how do I shim to the proper height?

Shimming is the use of thin metal shims, placed underneath the leveler frame, to set the leveler in the pit so that the deck is parallel to the pit floor, allowing the lip to reach the truck bed within the specified operating range. Shims should be used at the prescribed support points, and step 1 should be repeated. Make sure that the shim stack is secured. Proper shimming aids in the prevention of uneven wear, binding, and premature failure.

How do I position and lift the leveler into the pit safely?

Use lifting equipment rated for the leveler’s weight and follow the installation instructions for the designated lift points. Lift the leveler vertically and lower it into the pit while keeping it parallel to the pit floor and aligned with the pit edges. Assign personnel to guide the unit and prevent contact with bumpers or pit walls. After placing the unit in the pit, secure temporary holds or tack welds before removing the lifting gear to prevent the unit from shifting under load.

What is step 1 of the installation, and what precautions should I take?

In step one, inspect the dock and pit by measuring the pit dimensions, ensuring the pit floor and walls are level and clean, and reviewing the installation guide for the loading dock leveler specifications. Precautions include de-energizing nearby circuit breakers, clearing the area of workers, and inspecting all lifting devices. Note the locations of control boxes and any obstructions under the structure to avoid damaging hoses, wiring, or the counterbalance system during the installation.

How do I test and operate the leveler after installation to avoid equipment damage?

After shimming, bolting, or tack welding, cycle the leveler through its full articulation and float cycles several times to ensure proper and smooth operation, correct counterbalance, and confirm the lip fully extends to the vertical and loading positions. Inspect for any binding, check the hold-down and bolt tightness, test the control box, and watch for any hydraulic leaks. Follow the manufacturer’s checklist to keep workers safe from moving parts and to prevent any damage to the equipment.

Reference Sources

- McGuire Dock Leveler Manual

This manual provides detailed insights into proper dock leveler installation and its importance for performance.

Read more here - Section 11 33 19.13 – Dock Levelers

This document outlines anchorage, pit sizes, critical installation clearances, and accessory items for dock levelers.

Read more here - McGuire Dock Leveler Manual (Alternate Source)

Another version of the McGuire Dock Leveler Manual, emphasizing installation as the foundation of dock leveler performance.

Read more here - Section 11 13 00 – Loading Dock Equipment

This document discusses mounting options, capacity, and other specifications for dock levelers.

Read more here - Applicability of the Confined-Space Standard to Dock-Leveler Pits

This OSHA interpretation discusses safety considerations for dock leveler pits, which could be classified as confined spaces.

Read more here