In Oman, a rapidly developing Gulf country, the modernization of industry is placing greater demands on facilities and equipment. Industrial Sectional Doors have become the preferred choice for factories, warehouses, loading docks and logistics due to their excellent performance and diverse application scenarios. In this article, we will discuss the application of industrial sectional doors and their derivatives in Oman’s industrial sites. And analyze their advantages in different environments in detail with technical parameters and practical examples, as well as provide relevant brand recommendations and application guides.

Industrial sectional doors applications in factory warehouses

In Oman, factory warehouses, the core nodes of industrial operations, demand the highest level of performance from their doors. Industrial sectional door provide excellent security and ease of operation in warehouses through their robust construction and efficient opening and closing functions. These door bodies are typically manufactured with high-strength materials that can withstand frequent use and harsh environmental conditions, ensuring the safety of materials inside the warehouse.

Technical features:

Opening and closing speeds: average opening and closing speeds between 0.5 and 1.2 meters per second, adapting to a variety of logistics needs

Material: made of galvanized steel or aluminum alloy, with excellent corrosion resistance and durability

Sealing performance: full perimeter sealing ensures stable temperature and humidity inside the warehouse, preventing dust and outside air from entering.

Case in point: A manufacturing company in Oman installed industrial lifting door in their main warehouse. After the installation, the logistics operation time of the warehouse was reduced by 20%, and the temperature control effect was significantly improved. The operational efficiency and safety of the enterprise was significantly improved.

Application of dock equipment system in loading docks

Loading docks are an important part of industrial logistics and require doors that are capable of high-frequency operation and fast response times. Sectional Overhead Doors play a key role in this environment. However, in order to improve loading and unloading efficiency and safety. They are usually equipped with dock leveler, dock shelter and other equipment to form a comprehensive dock equipment system.

Dock leveler, also known as adjusting plate, can adjust the height difference between the vehicle and the loading platform to ensure the smooth loading and unloading of goods. While DOCK SHELTER is used to seal the gap between the vehicle and the building, to prevent the outside air, dust and rainwater from entering the warehouse, so as to keep the loading and unloading environment clean and safe.

Technical features of dock equipment system:

Adjustment plate: Made of high-strength steel plate, with a loading capacity of several tons. Equipped with hydraulic or electric control system, easy to operate

Sealing device: DOCK SHELTER is made of weather-resistant materials, able to withstand extreme weather conditions and suitable for all types of vehicles.

System Integration: Industrial sectional doors seamlessly integrate with the DOCK LEVELER and DOCK SHELTER. Enabling efficient and safe operations at the loading dock.

Case Study: A major Omani logistics company introduced a complete DOCK EQUIPMENT system with industrial sectional doors. Dock leveler and Dock shelter to its loading dock, which significantly improved loading and unloading efficiency. Minimized weather-related delays and ensured the safety of the cargo during the loading and unloading process.

Industrial sectional door applications in the logistics industry

In Oman’s logistics industry, fast and secure door systems are essential to improve operational efficiency. Industrial Lifting Door is ideal for logistics centers and distribution warehouses due to its robustness. Flexible operation and good sealing performance.

Technical features:

Flexible operation: the door body adopts a multi-joint design, which can open smoothly and adapt to high-frequency logistics operations.

Thermal insulation: The door body is filled with high-density polyurethane foam. Which has excellent thermal insulation effect and reduces energy consumption in the warehouse.

Safety: Equipped with multiple safety devices, such as infrared sensors and safety locks, to ensure safe operation and prevent accidents.

Case in point: A logistics center in Oman has significantly improved its warehousing and distribution efficiency through the use of industrial lifting doors. And the safety and reliability of the equipment has also been highly evaluated by the customer. The thermal insulation of the doors has helped the organization save 15% on energy costs. While ensuring safe storage of goods.

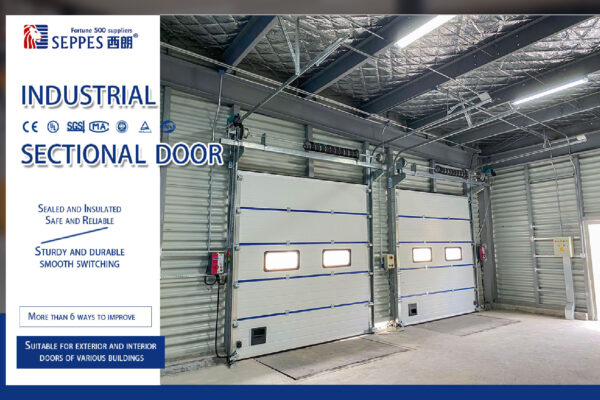

SEPPES’ presence and brand recommendation in the Asian market

SEPPES, as a well-known brand in the field of industrial doors. Has a good reputation in Oman and the whole Asian market. Its products such as industrial lifting doors and industrial sectional doors are widely used in various industries and trusted by customers due to their excellent performance and reliable quality.

In addition to SEPPES, brands such as Hörmann and RITEHITE also provide quality industrial door solutions in the Asian market. These brands are well known globally and customers can choose the most suitable brand and product according to their actual needs.

Application Guide and Future Outlook

Application Guide:

Choosing the right industrial door product for an industrial site in Oman is crucial. For factory warehouses, it is recommended to choose industrial lift doors with good sealing performance and durability. In loading docks, industrial sectional doors are the best choice for their flexible operation and high wind resistance to ensure smooth and safe operations. And in the logistics sector, industrial lift doors meet the needs of high-frequency operations. And energy saving due to their operational flexibility and good thermal insulation properties.

Future Outlook:

With the continuous development of Oman’s industry, intelligent and automated industrial door products will be more and more valued. SEPPES will continue to lead the industry by integrating Io T technology to realize remote control, real-time monitoring and automatic diagnosis functions of industrial doors. That will significantly improve the operational efficiency and safety of industrial facilities. In the future, SEPPES will continue to expand its product line in the global market, especially in Asia. And provide customers with smarter industrial door solutions through technological innovation.

Conclusion

This article discusses in detail the application of industrial sectional doors and its derivatives in Oman’s industrial sites. Combining technical parameters and actual cases to demonstrate the advantages and market performance of these doors. As Oman’s industry continues to grow. SEPPES and other leading brands will continue to leverage their leading edge to provide customers with superior door solutions and help modernize Asia’s industry.