High-speed doors are now present in almost every new warehouse being built today, reflecting the types of high speed doors that enhance operational efficiency. These doors play an integral part in operational improvements within the warehouse. The building of new modern warehouses is supported by new technologies that enhance productivity within the workplace. As technology advances, so do the requirements for operational excellence in the warehouse. When offered the choice of a basic door or a high-speed door, many people will choose the basic door. However, the high-speed doors provide a lot of value that many do not see. The purpose of this article is to educate the reader on the value of high-speed doors and why they are essential to the modern warehouse.

Introduction to High-Speed Doors

Unlike regular doors, high-speed doors are built to open and close much more quickly than average doors. High-speed doors open and close quickly, improving workflows and productivity, as they reduce closing time and improve time management. They are effective at improving and maintaining temperature, and losing less energy (and money) due to the openings in the environment. Their durability and speed are perfect for the warehousing, manufacturing, and food storage industries, where productivity and control are highly valued. High-speed doors improve workflow and productivity and are a requirement for modern industrial facilities.

Definition and Overview of High-Speed Doors

High-speed doors are made for busy places where speed, durability, and control of the environment are important. They open and close in a matter of seconds, helping people do their jobs while keeping the climate and energy use the same. You might find them in factories, warehouses, cleanrooms, and the automotive industry. These doors speed up work and help people do their jobs safely by preventing collisions in busy places.

Features and Benefits of High-Speed Doors:

Quick Operational Speeds

Cycle times can be further shortened with an open/close speed of more than 60 inches per second.

With increased speed, more air exchange is eliminated, enhancing control of temperatures.

Durability and Toughness

Some of the best reinforced PVC, steel, and aluminum are used to manufacture these doors.

Does not give up quality performance after prolonged use and severe conditions.

Superior Safety Features

Motion detectors, light curtains, and emergency stop systems are all present in high-quality types of high speed doors.

This greatly prevents accidents and keeps employees safe.

High Energy Savings

This helps save energy by keeping the atmosphere within the facility more controlled.

This is especially important for temperature-sensitive facilities, like food storage and pharmaceuticals.

Requires Less Maintenance

Some of them are designed to be mechanically simplified and have self-lubricating systems.

This makes the service costs much less and greatly enhances the doors’ reliability over time.

In today’s modern industrial facilities, high-speed doors are essential, providing efficiency, sustainability, and safety.

Importance in Modern Industry

In many different industries, high-speed doors are important because they help increase efficiency across several industries, including medicine, food, and storage. They keep a restrictive seal to regulate and maintain temperature.They boost productivity by moving people and goods rapidly, opening and closing quickly to maintain seamless flow and high traffic.

These doors also help improve the safety of a workplace. They help reduce the risk of collisions as well as keep people safe. Many people are allowed to help increase efficiency. They keep the flow of the environment closed and help keep the climate managed. This helps reduce the costs of energy as more people become low-income. This helps meet the demands of efficiency.

In the chemical and automotive industries, high-speed doors are utilized for their safety and energy-efficient capabilities, showcasing the benefits of high speed. In industries striving for innovation to improve the speed and productivity of their ops, the need for high-speed doors is more present due to their many benefits of high speed. These doors continue to help progress industries with the energy-efficient and safe practices that are present.

Key Benefits of High-Speed Doors

Maximized Productivity and Efficiency

A high-speed industrial door provides gainful vertical sliding doors for quick, prompt closing speed, and increased productivity in industrial and commercial operation systems. These doors open and close quickly, eliminating delays between high- and low-workflow areas and minimizing operational slowdowns. Advanced features create seamless and smooth operational performance, even in areas of high and dense human contact and movement. These features include motion detectors, safety systems, and automated operational systems.

In addition, these doors assist in maintaining the world temperature air exchange in less critical zones in temperature-sensitive areas of the food industry or pharmaceuticals. In addition, cutting-edge materials and construction of the doors provide low levels of maintenance and high construction on diligence. These door systems innovation levels include the Internet of Things (IoT), smart reporting diagnostics, and real-time performance, demonstrating the high-quality advancements in the market. With this level of technology, innovative systems can gain access to instantaneous stuff-level systems that can limit or even stop operational processes. With these systems, productivity can be improved significantly by fixing problems before they even happen.

Improved Energy Efficiency

When it comes to cutting down on energy spent to run an operation, high-speed doors are becoming a vital part of solving energy efficiency. By closing and opening quickly, high-speed doors keep any climate-controlled environment more energy efficient, and lose less energy due to doors opening and closing frequently. Modern high-speed doors have new features like smart technology to adjust to the environment and stay closed when foot traffic and vehicles are not moving through, and have heavier-duty, insulating seals to help keep the air in that climate-controlled space to stay in. All of these features add up to an environmentally friendly product that can help a business save money by reducing the energy it takes to keep the building in the climate it needs to be in.

Enhanced Security and Safety

High-speed doors, with both security and safety features, provide protection and efficiency in commercial and industrial environments. Modern high-speed doors use reinforced steel or high-strength fabric, making them resistant to tampering and forced entry. Additionally, these doors come with intelligent locking systems to provide additional security to protect valuable assets.

To keep your business safe, high-speed doors use advanced technology such as integrated sensors, light curtains, and automatic reversal systems. These features detect any people, vehicles, or things in the door frame to prevent the system from closing and will reduce the chance of injury or damage from closing. In the case of features not working, high-speed doors come with a manual release option to keep business operations moving during a power outage.

With the reinforced business technology and safe designs that these doors have, high-speed doors keep businesses safe and efficient. It allows facilities to provide safety compliance without losing performance.

Reduced Contamination and Improved Hygiene

Whether it’s the food processing industry, pharmaceuticals, or a cleanroom, fast-acting doors keep contamination and required hygiene levels in check. While fast doors have many features, the main benefit is their ability to reduce the time a door is open. Because they close quickly, the contamination from dust, dirt, and airborne spores is limited to a minimal time period. When it comes to hygiene, this is a highly effective model.

The modern high-speed doors, including the effective and advanced sealing technologies, make better barriers to outside contamination. They also come in models that are self-cleaning, and made of non-porous materials that are resistant to bacterial growth. To make sure that self-cleaning materials give no gaps for dirt to make a self-closure, some fast doors are even equipped with self-repairing mechanisms. Using the options discussed, fast doors help with meeting the hygiene standards while also protecting people directly in a facility’sthe end products and customers.

Major Applications Across Industries

Warehousing and Logistics

High-speed doors are valuable in the logistics industry as they streamline processes and help keep the goods moving in and out. They reduce time that could have been wasted on slow-moving processes. The time and productivity gained with the doors are especially valuable in cold storage facilities as they help maintain the indoor temperature. They are made to withstand heavy traffic, which reduces the wear and tear, leading to a longer lifespan. Other valuable innovations, such as automation and remote control, enhance operational efficiency and help secure productivity and safety.

Manufacturing and Production

High-speed doors are important for modern factories and production facilities and help to maintain efficiency and precise operational control. They help make sure operations are cycled through production lines seamlessly by facilitating high-frequency operations. They open and close rapidly, which minimizes downtime, improves workflows, and keeps the correct climate control. This is especially important for industries that work with materials and products that need to be kept at certain temperatures.

Manufacturing environments need strict hygiene and contamination control. High-speed doors with features such as smooth surfaces and air-tight sealing help to meet industry standards and are compliant with food and pharmaceutical standards. They are cost-efficient and are practical because of their durability and the ability to handle rough work environments, dust, and chemicals.

Modern high-speed doors use smart technology, including automated sensors and programmable logic controllers (PLCs), and integrate with Industrial Internet of Things (IoT) systems.These improvements make operational efficiency even better because of the ability to collect data and perform predictive maintenance. They easily work with other automated systems. High-speed doors keep production and manufacturing facilities running better by improving safety and reducing energy.

Food Processing and Cold Storage

High-speed doors are an exemplary answer to the food processing and cold storage industries’ needs for temperature control, door hygiene, and operational efficiency. These doors are made for environments with restrictions on temperature and rapid access. High-speed doors open and close rapidly to minimize air exchange, reduce refrigeration costs, and prevent food waste. Made from easy-to-clean, food-grade materials, they keep processing areas safe from contamination. Automation and modern technology optimize door performance and integrate seamlessly with operating systems. Increasing regulatory demands make high-speed doors essential, while their energy-efficient design helps lower overall energy costs.

Pharmaceuticals and Healthcare

Ensuring the safety and sterility of the environments where pharmaceuticals and healthcare are being done is the biggest concern, and fast doors help with that tremendously, by also being more efficient. These doors also serve to control the environment. These doors meet the highest standards of safety and cleanliness required in cleanrooms, laboratories, and hospitals. In addition to the environments mentioned, high speed doors are also useful in other sensitive cases, and are useful for allowing swift closure and reduction of air and outside particles. Moreover, the smooth surfaces of the doors make them easy to clean and also comply with the FDA and GMP standards.As the world automates and more people adopt IoT, manufacturers can design doors to meet specific environmental standards, ensuring safety remains a priority.These doors are also an incredible asset in the simplification of workflows.

Retail, Commercial, and Hospitality

High-speed doors are increasingly becoming a vital component in the retail, commercial, and hospitality sectors. Their quick operation helps improve customer experience by enhancing ease of access and maintaining optimal indoor temperatures, particularly in areas with high foot traffic. These doors also contribute to energy efficiency by reducing heating or cooling loss, which is especially valuable in large commercial spaces or open-plan venues. With advancements such as modern sensors, automation, and sleek designs, high-speed doors blend functionality with aesthetics, making them ideal for hotels, restaurants, shopping malls, and other facilities where appearance and efficiency play a critical role. Additionally, their ability to minimize noise and create a more controlled environment makes them an attractive choice for ensuring both employee comfort and a pleasant customer experience.

Automotive Industry

In the automotive sector, high-speed doors greatly improve safety, efficiency, and workflow within service centers, manufacturing plants, and storage facilities. The automotive industry operates at a fast pace, with rapid movement of parts, tools, and vehicles. By integrating the latest technologies, such as programmable controls and motion sensors, high-speed doors maintain operational standards and keep facilities climate-controlled. Controlling dust, debris, and temperature fluctuations protects component quality and ensures precise assembly work. High-speed doors are the most reliable and durable solution when it comes to optimizing the performance of automotive divisions.

Agriculture and Livestock Operations

High-speed doors offer critical support to livestock and agricultural operations. Critical support to livestock and agricultural operations because of their efficiency, hygiene, and environmental control features. Withstanding harsh agricultural environments such as heavy traffic, dirt, dust, and changing weather, these doors support rapidly accelerating workflows with their quick open and close capabilities. Supporting sustained indoor climates, which are critical to animal welfare and the storage of crops, is also part of their efficiency offerings. They also reduce energy loss.

In addition to supporting operational efficiency, high-speed doors also reduce the spread of contaminants and pests, creating a safe habitat for livestock and produce. The history of the doors also offers insulation adaptation, Seal and automation control customization to meet the diverse needs. Operationally simple and durable. Cost-effective, focused on the sustainable and productive operations.

Aerospace, Defense, and Public Infrastructure

All three industries depend on high-speed doors for their efficiency and reliability in demanding situations. The doors have rapid-open and close functions to keep the surrounding environments from being exposed for extended periods of time. High-speed doors in aerospace environments allow for the control of enclosure climates and the assembly/maintenance of the aircraft. The doors reduce the spread of contamination and maintain precise temperatures. In the defense industry, high-speed doors protect bases and storage facilities while simultaneously providing critical, rapid access to stored equipment/vehicles. In public infrastructure, high-speed doors support and facilitate the increase in operational efficiency of the doors. High-speed doors can meet the stringent requirements of the industry and provide unparalleled operational efficiency.

Energy, Utilities, and Mining

High-speed doors are used in the US, Canada, energy, utilities, and mining industries. It reduces energy consumption, saves time, and improves safety and efficiency. High-speed doors are used in extreme environments with large vehicles and lots of dust. High-speed doors in power plants, oil refineries, mining, and distribution centers help streamline processes and enhance safety. In mining, high-speed doors control temperature and dust when storing valuable minerals and equipment. In the energy sector, high-speed doors are in wind turbine hubs and power substations. These doors keep sensitive equipment from extreme weather while providing quick access. Water treatment and Waste management facilities in the untry Canada utilities sector utilizes high-speed doors. These doors improve workflow and reduce the possibility of cross-contamination. High-speed doors are designed with automation and weather-resistant technology. These doors are the best option for companies looking for optimal performance, minimal downtime, and reduced energy consumption.

Types and Key Features of High-Speed Doors

Material Options for High-Speed Doors

PVC (Polyvinyl Chloride) is one of the high-quality materials used in the manufacturing of rubber doors for high-speed applications.

Because of PVC’s flexibility and light weight, it makes it very popular and useful for high-speed doors. Due to its high durability and ability to withstand some impacts, it is great for places where high-frequency impacts occur. PVC also has great temperature resistance, which helps keep some places energy efficient.

Aluminum

Aluminum is a very useful material for high-speed doors, due to its ability to combine strength and corrosion resistance while ensuring minimal maintenance. This is great for outdoor applications because of the changing climate conditions. Aluminum is also very lightweight, which allows the door to function more quickly.

Stainless Steel

Stainless steel is also great for high-speed doors due to its high strength and, more importantly, its durability. Stainless steel is a door material that is great for food processing, pharma, and cleanroom applications (which require a lot of sanitation due to their high demands). That can withstand all types of rust and contamination, so its sanitary requirements can be met with no problem.

Insulated Panels

Using high-speed doors with insulated panels works best in climates that require controlled temperatures, such as cold storage or sensitive production facilities. Excellent thermal insulation reduces energy costs and helps maintain a consistent temperature.

Reinforced Fabric

Reinforced fabric is for lightweight environments, where flexibility is a high priority due to the added strength of the woven or embedded layers fabric. This makes them more resistant to high winds and heavy use, which is ideal for industrial applications like logistics.

Customization Options for High-Speed Doors

Businesses can customize high-speed doors depending upon industry to maximize performance. The following are five prominent customization options:

Dimension & Size

High-speed doors can be designed to accommodate specific openings. This is especially useful for facilities with doors that are not within the standard size range.

Opening & Closing Velocity

How quickly or slowly the doors need to open and shut can be customized based on the workflow. For areas that are very busy and need to improve workflow efficiency, faster doors are ideal.

Choice of Materials

According to the needs of the application, customers can choose between materials like reinforced fabric, insulated steel, or PVC. For example, insulated materials are optimal for environments that are temperature-regulated.

Safety Additions

High-speed doors include extra safety features such as emergency stop systems, light curtains, and motion sensors, which ensure safe operations in high-traffic areas.

Color Customization & Branding

Doors can be customized with specific colors, patterns, and company logos to improve brand recognition and the look of the facility. This is especially advantageous to use during high traffic times to show professionalism in areas that customers see, as high performance doors can help manage flow.

Safety Features in High-Speed Door Systems

High-speed door systems contain many safety features advanced enough to keep people, equipment, and products safe. The following lists five important safety features found in these types of high speed doors.

Motion Sensors

Motion sensors know when there is something near the door and will prevent the door from closing, keeping it open if a person or object are in the way.

Light Curtains

Light curtains serve as a safety technology positioned at the top and bottom of a door opening, forming an invisible fence. When someone or something crosses or interrupts this fence, the door stops closing and opens immediately.

Emergency Stop Systems

In urgent situations, integrated systems prevent accidents by using an emergency stop button that instantly halts the door’s closing.

Soft Edge Technology

Soft-edge technology features flexible, rounded door edges that prevent collision damage and minimize the risk of injury to people, vehicles, or the door itself.

Automatic Reverse Mechanism

In the event a door is closing and hits an object, the automatic reverse mechanism ensures the door will reverse rather than continue closing, avoiding damage to people or products.

Providing a safe environment is an important function of high-speed doors and is why these systems are designed as they are.

Selection Tips for Specific Applications

Evaluating Speed and Cycle Rating

Operational speed and cycle rating are two key performance metrics that should be reviewed during the selection of high-speed doors for various applications. Reducing energy expenditure and keeping climate control in place are two advantages of the quick opening and closing mechanisms found on high-speed doors. Different manufacturers offer a wide variety of speed capabilities across their different models. The speed can be anywhere between twenty inches per second and one hundred inches per second. Volume and frequency of traffic flow, temperature control, and overall efficiency of the workflow are factors that determine the need for speed in a given operational environment.

As far as cycle rating is concerned, this metric refers to the number of opening and closing motions that a high-speed door can accomplish while still preserving its functionality and structural integrity. Consider an example of a manufacturing operation that involves warehousing and cold storage. The operational design of these systems demands that doors be able to handle hundreds to thousands of these cycle raters daily, showcasing the types of high speed doors available. Selecting high-rated cycle doors can be an advantage in that the operational downtime is minimized, as well as the maintenance costs in the long run, ensuring high performance.

Also, when looking at new doors, businesses can incorporate modern technology like variable speed drives and programmable logic controllers (PLCs), which can integrate with automation and allow for fine-tuned control over door speed. Taking into account operational needs, power consumption, and the balance of speed with cycle rating, companies can optimize doors for productivity and cost savings.

Maintenance and Service Considerations

Selecting doors with vertical or horizontal openings involves maintenance and servicing implications for long-term reliability and performance. Schedule maintenance strategically to address component issues and sustain performance and reliability. Regularly maintain door components such as rollers, door seals, and motor systems to keep performance and reliability high.

Choosing door suppliers with reliable after-sales support, maintenance spare parts, and technical support, responsiveness, is paramount. Advanced monitoring, such as door sensors and IoT systems, can assist with maintenance by automatically providing information to support decisions regarding servicing the door and issues that may be developing.

Service requirements depend on environmental conditions. High-speed doors with insulated materials and heating elements that resist condensation perform well in cold storage environments. Using highly durable materials in high-traffic areas reduces the need for frequent servicing. Balancing these issues with operational requirements will achieve the business objectives to support functionality of the doors while optimizing the costs associated with repairs and interrupting operations.

Custom Design for Unique Facility Needs

Facilities can tailor high-speed doors to meet their specific needs and ensure optimal performance. The doors offer many customizable options, which are explained below.

Door Material and Finish

Available Materials: PVC, stainless steel, and galvanized steel.

Details: Stainless steel works best in industries that are hygiene sensitive, such as food processing, while PVC is flexible and more economical.

Speed of Operation

Available Options: Speeds can be adjusted from 20 inches per second to a maximum of 100 inches per second.

Details: Higher speeds are best for facilities with a lot of activity, as it boosts efficiency and decrease the amount of air that passes through.

Insulation and Thermal Protection

Available Options: Double-layer insulated panels with thermal breaks.

Details: This is useful for cold storage and climate-controlled zones as it can save up to 30% in energy costs.

Safety Features

Available Materials: Integrated edges with sensors, radar motion detection, and light screens.

Details: More advanced safety systems decrease accident potential while ensuring compliance with safety regulations in the industry.

Size Customization

Available Options: The doors can be customized in height and width from 8 feet to more than 20 feet.

Details: Tailored sizes allow for different purposes. These can range from small factory divisions to large industrial storage spaces.

Adjusting these features to fit operational demands and environments allows for high-speed doors to deliver maximum performance, cut expenses, and improve safety in a diverse range of industries.

Future Trends and Innovations in High-Speed Doors

IoT and Smart Controls in High-Speed Doors

The IoT (Internet of Things) and smart controls are likely the most recent developments in the high-speed door industry. It allows the door to communicate with a central system and lets the user monitor and open and close doors remotely. High-speed doors have sensors that collect cycle counting and performance data, and they can sense when they need maintenance. This data helps with smarter management by informing them of maintenance and repairs before they become problematic.

Smart controls can also help save energy by fine-tuning how a door is used. An example of this is in a controlled environment where the doors open and close frequently. Instead of wide-open doors that expel a lot of controlled air, smart controls can automate an adjustable door that closes quickly to limit air lost to the system.

The IoT also helps link the doors to other systems in a warehouse, like management systems and security. Overall, the recent changes in high-speed doors have led to smarter systems and more connected environments. This results in a safer and more productive environment.

Advanced Materials for Energy Efficiency of High-Speed Doors

Materials used in constructing high-speed doors greatly improve energy efficiency and sustainability in industrial settings. Certain materials reduce energy loss, improve thermal insulation, and better regulate internal environmental control. Below are five materials used in the construction high speed doors.

Polyurethane Foam (PU Foam) – This foam has great thermal insulation and can reduce the energy needed to regulate temperature.

High-Density Polyethylene (HDPE) – This lightweight material is great to construct energy efficient doors, and is great at resisting temperature.

Aluminum with Thermal Breaks – Thermal breaks in door frames are an effective and efficient method to improve insulation and increase energy efficiency.

Low-Emission Glass (Low-E Glass) – This glass can regulate temperature and, with high-speed doors, improves thermal regulation without compromising visibility.

Advanced Weather Seals. The cutting-edge high-speed doors now incorporate weather seals that reduce energy loss and block the intrusion of air. Weather seals are constructed from EPDM material, which stands for Ethylene Propylene Diene Monomer. This rubber material provides excellent insulation and long-lasting durability.

Combining all of these materials leads to considerable energy savings and meets the demands of today’s industries.

Enhanced Customization Features

The adaptable nature of high-speed doors is what makes them an essential part of many industries. Some high-speed door custom features are:

Adjustable Sizing: Almost any door frame can be filled with a high-speed door, from internal doors to major warehouse entries.

Custom Color Selection: You can coat high-speed door frames in multiple colors to match corporate branding or maintain a uniform workplace appearance.

Changing the Rate of Operation: Doors can be configured to open and close at different rates to maximize workplace efficiency.

Panel Material Alteration: Depending on what industry is using the high-speed door, different panels are available. Options such as aluminum or PVC can be used to fit varying industry standards and extreme conditions.

Custom Safety Features: Depending on the industry using the high-speed door, different panels are available. Options such as aluminum or PVC can be used to fit varying industry standards and extreme conditions.

The high-speed doors can be used in any industrial setting, with the ability to customize from a variety of options.

Conclusion

Summary of Benefits of High-Speed Doors

Speed doors are beneficial to many businesses in industrial and commercial spaces. Here are some of these vital benefits:

High Opening and Closing Speeds: High-speed doors are an optimal storage solution to best use your building’s logistic points. They can save your operations a minimum of 20% and improve your efficiency. Taking less time to open and close improves workflow.

Lower Energy Consumption: When doors close faster and spend less time open, your heating and air conditioning do not run as much. This means less energy is consumed. An energy savings of 30% can be achieved while lowering your carbon footprint.

Increased Safety: Safety is one of the primary concerns in high-speed doors. Safety measures such as light curtains, motion detection, and pressure-sensitive edges keep your it and your assets protected.

Better Air Quality: High-speed storage doors can keep the inside of your building cleaner by restricting the amount of dust and other contaminants from entering problematic areas. This is especially beneficial in more regulated environments, such as in food and drug production.

Long-lasting and cost-effective: Modern speed doors are constructed from more durable materials. This design enables them to withstand higher wear and tear while requiring less maintenance. This results in a reduction of your downtime and costs.

These benefits highlight the importance of high-speed doors in industrial operations. They aid in providing a seamless, safe, and energy-efficient workflow.

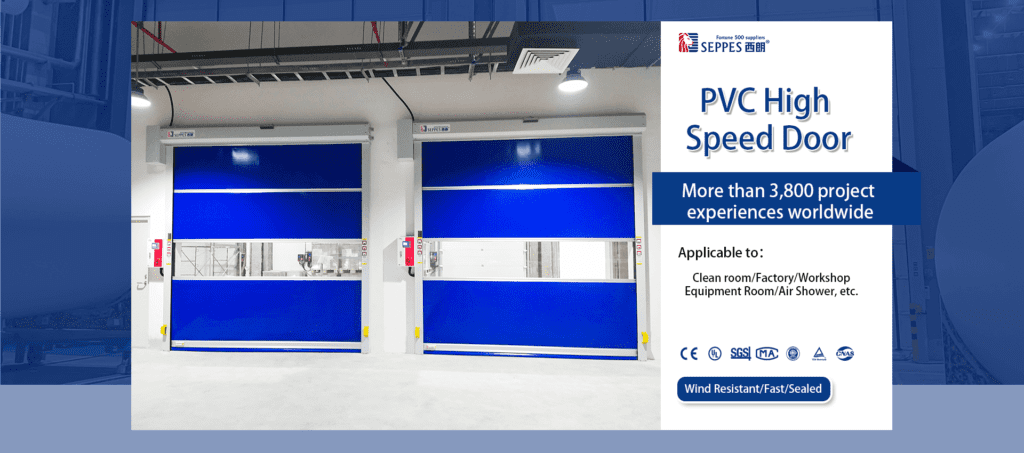

Encouragement for Tailored Solutions

Every industrial environment has its challenges. At SEPPES Door Company, we want to tackle those challenges with our tailored high-speed door. We offer high-speed door solutions that are energy efficient, improve workflow, and promote safety. SEPPES door company custom-fits high-speed doors to ensure they are perfect for your operations. We work with you to guarantee that your high-speed door system is a perfect fit for your facility.

Frequently Asked Questions (FAQs)

What is a high-speed door, and how do high-speed overhead doors work?

A high-speed door, also called a speed door, serves as an overhead air door that opens and closes quickly to manage traffic and control an environment’s air quality.They consist of powerful, streamlined motors, reinforced guiding tracks, and a variety of closing curtain materials (rubber, fabric, or sectional doors), which help to minimize open and closing duration. These attributes help to reduce drafts, contamination, and the loss of energy in commercial and industrial settings.

What are the different types of high-speed doors and types of high-speed doors available?

High-speed doors include high-speed roll-up doors (also called rapid roll doors or high-speed roll-up doors), fabric section doors, and high-performance models for heavy-duty or cleanroom applications. Manufacturers design these doors for interior or exterior use, using various materials and constructions to meet the demands of industrial, commercial, or cleanroom operations.

Where are high-speed doors used, and what exterior applications suit rolling doors?

High-speed doors appear most often in warehouses, manufacturing floors, food processing areas, and loading docks. For exterior applications, facilities usually choose roll-up and rolling doors.These designs are especially energy-saving and secure while also offering protection from the elements, which contributes to reducing energy costs. Rolling and roll-up doors are the most commonly used for high-traffic exterior commercial doors.

What are the main benefits of high-speed doors, and how do speed doors improve efficiency and productivity?

Some benefits high-speed doors provide include decreased time for opening and closing cycles, improved energy savings, better climate control, faster workflow, reduced risk of contamination, and improved climate control and energy savings by reducing air exchange. Because rapid doors have faster cycle rates than traditional doors, they lead to improved throughput and faster efficiency, along with productivity by reducing downtime and keeping internal environments consistent.

How do high-performance doors and rapid roll doors contribute to durability and long-term reliability?

Manufacturers construct rapid roll doors and high-performance doors with heavy-duty materials and reinforced drive systems to endure constant cycles. Engineers design high-performance models to withstand demanding commercial environments, resist corrosion, and feature heavy-duty custom components that simplify maintenance.

How do high-speed doors improve energy savings and control airflow?

High speed door have improved energy savings by closing the opening of the doors faster. In retail environments where cross-contamination with consumers is a concern, these doors are optimal to control airflow rapidly, preserve climate zones, and reduce the load on your HVAC. Improved process control and measurable energy savings are benefits for conditioned and refrigerated environments.

How do I choose the right door or determine which doors are best for my facility?

The type of door you select depends on its intended purpose (inside or outside), the desired opening and closing speed, the frequency of use (traffic), the level of environmental control needed (cleanroom vs. industrial), and the degree of protection required (security and safety).Consider whether you want a fabric door, roll up door, a sectional door, or a high-speed roll-up door. If you want to balance workflow, durability, and energy efficiency with high-speed industrial doors and high-speed commercial doors, you should consult a high-speed industrial and commercial door supplier.

What maintenance do high-speed roll-up doors and rolling doors require to keep them working?

The inspection of high-speed roll-up doors for the following is an important part of the maintenance process: safety sensor functions, curtain integrity, drive belts and motors, lubrication, and moving part adjustments. To save time on maintenance for high-speed roll-up doors, you should schedule your maintenance to prevent downtime and to save on repairs. Many high-speed roll-up doors are equipped with maintenance contracts to save time and to ensure a high level of performance.

Are high-speed doors safe for people and goods, and how do safety features work?

High-speed doors include safety features such as photoelectric sensors, reversing edges, soft bottom edges, and obstacle detection to prevent collisions with people or vehicles. Obstacle detection stops the door and reverses it automatically to avoid accidents. Proper installation and regular maintenance ensure the doors operate safely and allow users to fully benefit from their high-speed safety features.

Can high-speed doors be customized for specific needs like clean rooms or harsh conditions?

You can tailor high-speed doors to fit unique environments. For example, fabric doors and high-performance doors can be used in clean rooms, temperature-controlled rooms, and harsh/outdoor corrosive environments. Different curtain materials, insulation, sealing methods, and control systems are available to meet specific needs. Custom high-speed doors enhance cleanliness, energy savings, and productivity in specialized applications.

Reference Sources

- Advances in High-Speed Store Separation for Upward Flow

- Link to study

This study explores computational fluid dynamics and motion analysis in high-speed flow, which may provide insights into the engineering aspects of high-speed doors.

- Link to study

- Division 8 Doors & Windows (Utah State University)

- Link to document

This document discusses specifications for doors, including high-speed and automatic doors, in construction and facility management.

- Link to document

- Penncom: Coordinating the Eyes and Ears of Public Safety

- Link to article

This article includes information on door systems with electric locks and monitoring, which could relate to high-speed door applications in security.

- Link to article

- Section 08 33 13 – Coiling Counter Doors (VA Vendor Portal)

- Link to document

This document defines high-speed doors as a subcategory of high-performance doors, primarily used for vehicular access in material handling.

- Link to document

- 34 Pa. Code § 7.54. Landing Doors and Locking Devices

- Link to regulation

This regulation outlines safety and accessibility standards for doors, which may include high-speed doors in specific applications.

- Link to regulation