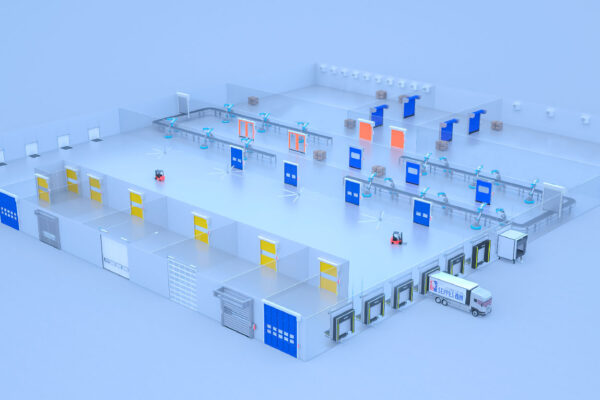

In modern industrial scenarios, speed doors are widely used in various industries such as logistics, food processing, and electronics manufacturing due to their high efficiency, safety, and energy-saving features. If you’re in the process of selecting the right high speed door for your project, you need to understand its composition, pricing, supplier selection and future market trends from multiple perspectives. This article will take you through nine key points to gain a comprehensive insight into all aspects of a speed door and help you make an informed decision.

1. what is a high speed door?

Rapid door is a kind of industrial door that can realize rapid opening and closing, mainly used in areas that require efficient access, clean environment and temperature control. Compared with traditional doors, the opening and closing speed of the rapid door is faster, usually between 0.8 and 1.5 meters per second, which can greatly improve logistics efficiency, reduce energy consumption and maintain cleanliness.

Common application scenarios include logistics warehouses, food processing plants, clean rooms, cold rooms, etc. The characteristics of the fast door make it an ideal choice for these locations.

2. the composition of the speed door

The performance of rapid doors is closely related to their composition. Understanding these components helps to assess the quality and applicability of the product:

Door curtain material

PVC material: lightweight and durable, suitable for clean rooms and food factories, with waterproof and dustproof function, easy to clean.

Transparent curtains: Transparent materials are used in places where visual monitoring is required, such as production plants.

Thermal insulation material: commonly used in cold storage and temperature control areas, with significant thermal insulation effect.

Motor

High-quality motor can support long time and high frequency use, ensuring the stability and durability of door opening and closing.

Control system

PLC control system: Intelligent control, able to integrate with sensors and remote operation equipment to realize automated management.

Safety system: Equipped with infrared sensors and bottom airbags to ensure safe operation and prevent accidental injuries.

Track and sealing strip

High-quality tracks and sealing strips determine the wind resistance and sealing performance of the door body, which can effectively prevent the entry of external air and dust.

3.The basic classification of the high speed door

Rapid doors can be categorized as follows according to different usage scenarios, functions and materials:

Classification according to the opening mode

High Speed Roll Up Door: suitable for frequent entry and exit places, which can improve the efficiency of logistics.

Zipper High Speed Door: with self-healing function, suitable for clean room and high cleanliness requirement area.

High Speed Spiral Door: Strong wind resistance, suitable for outdoor use.

Machine Protection Door: Specialized for equipment protection, providing quick isolation.

Classification according to material

Fabric Roll up door: Suitable for clean environments, lightweight and durable.

Transparent High Speed Door: suitable for areas requiring visualization, such as production line monitoring.

Insulated High Speed Door: good heat preservation, commonly used in cold chain logistics and constant temperature production places.

Classification according to application scenarios

Logistics warehouse: high speed rolling door or high speed stacking door to improve logistics efficiency.

Clean room: doors with strong sealing performance are needed, such as high-speed zipper door.

Cold storage and constant temperature workshop: suitable for door body with strong heat preservation performance.

4. Product technical parameters and recommendations

When selecting a fast door, you need to understand the technical parameters of the door body, which will directly affect its performance.

Opening and closing speed

The opening and closing speed is usually between 0.8 and 1.5 meters per second, which is suitable for high-frequency traffic areas.

Wind resistance

Depending on the environment, the door body needs to have wind resistance, such as for outdoor fast doors need to have a higher level of wind resistance.

Thermal insulation effect

For cold storage and constant temperature workshop, the U-value (thermal conductivity) of the door body is an important index to measure the heat preservation performance, the smaller the U-value, the better the heat preservation effect, usually less than 1.0 W/m²K door body has good heat preservation effect.

Safety performance

Whether the door body is equipped with infrared sensors, automatic response device and other safety features to ensure that the door will not be accidentally closed when an object passes through.

5. Factors affecting the price of speed doors

When shopping for a fast door, the price difference is mainly affected by the following factors:

Material

The material of the door curtain and the size of the door will directly affect the price. For example, the cost of transparent materials, thermal insulation door curtain is usually higher.

Opening and closing speed

The faster the opening and closing speed, the corresponding increase in the cost of the door body, especially in efficient logistics scenarios, the opening and closing speed of the rapid door significantly affects the operational efficiency.

Motor and control system

High-quality motors and intelligent control systems (e.g. PLC systems) are more expensive but can provide better performance and safety.

Customization needs

Customized doors (e.g., size, color, functionality) based on the needs of the premises can affect the price. If special insulation, wind resistance or cleanliness features are required, the price will be relatively higher.

6. How to choose the right supplier for the rapid doors?

Selecting a reliable supplier is very important to ensure product quality, technical support and after-sales service. Below are a few factors to consider when choosing a supplier:

Certification and quality standards

Ensure that the supplier’s products have passed international certifications, such as CE certification, which is the basic guarantee of the quality of the rapid doors.

Customization capability

Quality suppliers should provide customized solutions to meet the needs of customers in specific scenarios.

After-sales service and maintenance

Whether the supplier provides comprehensive after-sales support, including regular inspection, maintenance and technical support, which is crucial for the long-term use of the door.

Brand reputation

Choose supplier brands that are well known in the market, such as SEPPES, Hörmann and ASSA ABLOY, which have good market reputation and rich industry experience.

7. Key points when choosing and buying speed doors

When choosing and purchasing fast doors, the following key points need special attention:

Scene demand

Understand the use of rapid door scene and functional requirements. For example, the door body of the logistics channel needs to be opened and closed quickly, while the cold storage door body should have good heat preservation performance.

Speed and energy efficiency

High-speed doors can improve efficiency, but to ensure that the opening and closing speed and the use of the scene match, while taking into account the energy consumption.

Safety

The door body of high-frequency access places should have infrared sensors, automatic response devices and other safety measures to avoid accidents.

8. Purchase the time point of the high speed door

Planning stage

In the project planning stage in advance to choose the right fast door, to ensure that it meets the architectural design and functional requirements.

Construction phase

During the construction process, keep close contact with the supplier to ensure that the installation of the door body conforms to the design specifications and avoid rework at a later stage.

Maintenance and Upgrade

Regularly maintain and check the performance of the door body, and carry out timely maintenance or upgrading to ensure the long-lasting use of the door body.

9. Future outlook and brand recommendation

With the development of industrial intelligence, the rapid door in the future will pay more attention to intelligent control, energy saving and environmental protection and other characteristics. Door body combined with the Internet of Things technology will become a trend to help enterprises realize remote monitoring and automated management.

Brand Recommendation:

SEPPES: Provide diversified industrial door products, with global sales and after-sales network.

Hörmann: Germany’s leading industrial door manufacturers, focusing on high performance and quality.

ASSA ABLOY: the world’s leading supplier of door control technology, providing innovative intelligent door body solutions.

Through the above nine key points, customers can comprehensively understand how to select the right fast door from the composition of the door body, technical parameters, price influencing factors and supplier selection and other aspects, so as to ensure that the project is carried out smoothly and obtain long-term benefits.

More Information about High Speed Doors:

High Speed Doors: A Comprehensive Guide to Types and Global Market Demand

High Speed Doors: A Comprehensive Guide to Types and Global Market Demand