The Critical Role of Industrial Door in Puerto Rico

As a major manufacturing and logistics center in Latin America, Puerto Rico has seen an increase in the demand for safety, efficiency and environmental control in various industrial sites. Industrial doors play a vital role in these locations, not only protecting facilities and materials, but also ensuring optimal production and storage by effectively regulating environmental conditions. With the rapid growth of the Puerto Rican industry, there is a growing market demand for high-performance industrial doors. In this article, we will explore in detail the application of several major industrial door types in Puerto Rico’s production halls, logistics industry, and factory warehouses.

High speed doors in the production plant

Definition and Characteristics of High-Speed Doors

High speed doors are designed for industrial environments with frequent use and rapid opening and closing. Its most important feature is the fast opening and closing speed, usually between 1 meter and 2 meters per second. This speed advantage not only greatly improves logistics and transportation efficiency, but also effectively reduces air convection, maintains stable temperature and humidity in the workshop, and saves energy.

Application Scenarios and Benefits

High-speed doors are ideal for use in Puerto Rico’s production halls, especially where frequent access occurs. Their fast response time significantly reduces the temperature difference between the inside of the workshop and the outside environment, which helps maintain product quality, especially in production processes with strict temperature requirements. In addition, the automated control system of the high-speed door can also reduce manual operation and improve the productivity of the workshop.

Technical parameters and recommended models

For example, a certain model of high-speed door is equipped with a 0.75kW motor, the maximum speed of up to 2.0m/s. The curtain material is high-strength PVC, wind resistance class 3. This door is not only suitable for general production workshop, but also in the more demanding environment to play to its advantage.

Spiral doors in the logistics industry

The unique design and structure of the spiral door

The spiral door, as a high-performance industrial door, is named for its unique way of storing the door curtain. The curtain is rolled into the spiral track when opened, saving space and reducing wear and tear on the door body. Spiral doors are usually made of aluminum or steel, providing excellent durability and safety.

Demand for applications in the logistics industry

Spiral doors are widely used in the logistics industry in Puerto Rico, especially in large warehousing and sorting centers. These locations often require doors that can be opened and closed quickly to speed up the movement of goods in and out of the facility. And that can withstand high-frequency operations without damage. The spiral door perfectly meets these needs with its robust structure and efficient operation mechanism.

Technical Parameters and Example Analysis

For example, a certain model of spiral door adopts double-layer aluminum alloy plate with a thickness of 40mm. Which has good sound insulation and heat insulation effect. With an opening and closing speed of 1.5m/s, it is suitable for logistics centers with frequent operations.In addition, the door’s intelligent control system links with the warehouse management system, further improving operational efficiency.

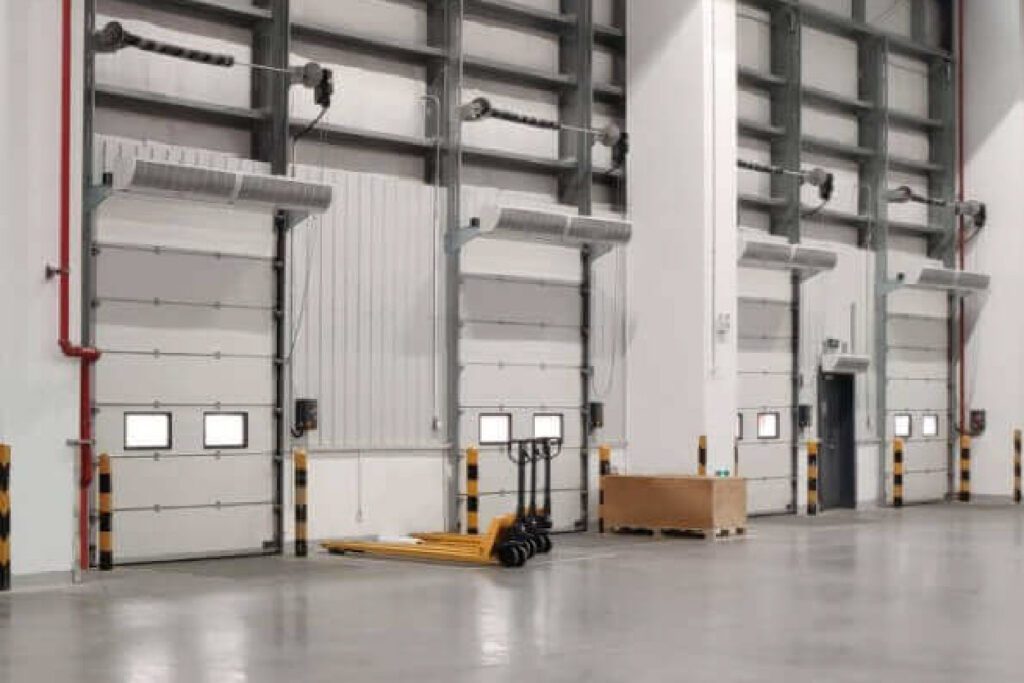

The application of industrial sectional door in factory warehouse

The basic principle and structure of the sectional door

A sectional door is an industrial door that utilizes a track system to slide the door body upward and stow it horizontally under the ceiling. Its space-saving design allows the door to open without occupying an effective area inside the warehouse. Sliding doors are usually made of steel and have excellent load-bearing capacity and wind resistance.

Factory Warehouse Scenarios

In Puerto Rico’s factory warehouses, sectional doors are particularly used. As space is often at a premium in warehouses, industrial sectional doors are designed to maximize the use of space and ensure smooth transportation of goods. Their high-strength construction can withstand the impact of heavy forklifts, making them ideal for warehouse entrances and exits.

Technical parameters and application guide

A certain model of industrial sectional door thickness of 50mm, using double-layer galvanized steel, filled with high-density polyurethane foam. With excellent thermal insulation effect. The door has a maximum load capacity of 1000 kg and a wind resistance of Class 4, which makes it resistant to wind pressure in extreme weather conditions.In addition, you can equip the sectional door with an emergency manual opening device to ensure it remains usable in the event of a power failure or malfunction.

Integrated application of rolling shutter doors in production workshops and warehouses

Flexibility and Practicality of Rolling Doors

Roller shutter door is a widely used industrial door, favored by many industries for its simple structure and easy operation. Roller shutter door consists of a series of interconnected metal strips or mesh materials, the door body is driven by the motor to roll upward when opened, minimizing the occupied space.

Diverse needs of production plants and warehouses

Rolling doors offer flexibility and durability, making them widely used in Puerto Rico’s production plants and warehouses. These locations often require doors that can respond quickly to ensure the efficient operation of production and logistics. But also require good durability and stable operation for a long time. Roller shutter door is excellent in these aspects, is a variety of industrial places of choice.

Technical parameters and brand recommendation

For example,SEPPES industrial rolling door using high-strength aluminum alloy material, the thickness of the door plate is 20mm. With good wind resistance and heat insulation effect. Its motor power is 1.0kW, opening and closing speed is 1.2m/s, suitable for most industrial environments. Other high-quality brands such as Hörmann and Switzerland also have rich experience and excellent product performance in the field of rolling doors, customers can choose according to specific needs.

Industrial Doors Application Guidelines and Purchasing Advice

How to choose the right industrial door

When choosing the right industrial doors for industrial sites in Puerto Rico, customers should first consider the specific application scenarios and needs. For places that require high-frequency operations, such as logistics centers and production plants, high-speed doors or spiral doors are ideal. For warehouses with high space utilization requirements, sliding doors provide a better solution. Roller shutter doors are suitable for places where flexibility and durability need to be balanced.

Installation and maintenance advice

Proper installation and regular maintenance are essential for the longevity of industrial doors. Selecting an experienced and professional team for the installation process ensures accurate and safe door installation. Regularly checking the operating status of the door body, the working condition of the motor. And the sensitivity of the control system can greatly extend the service life of the door body and reduce maintenance costs.

Industry Comparison and Future Outlook

In the global industrial doors market, the demand for industrial doors in Puerto Rico, North America market is growing year on year. With the progress of science and technology. Future industrial doors will focus more on intelligence and automation to further enhance productivity and safety. Customers should pay attention to the brand’s technical strength and market reputation to ensure that they buy the most suitable products.

Industrial Doors Intelligence and the Future of Development

Trends in Intelligent

With the development of IoT technology, the use of intelligent industrial doors is gradually increasing in Puerto Rico’s industrial sites. These doors are capable of increasing automation in production through remote monitoring and control while reducing human error. This trend is expect to grow further in the future and become a staple in the industrial door industry.

Future Market Prospects

In the future, the industrial doors market in Puerto Rico will focus more on energy efficiency and smart controls. High-performance and low-energy-consumption door bodies will become mainstream. While intelligent operating systems will help companies further improve productivity and reduce operating costs.

Conclusion

Choosing the right industrial door is crucial in all types of industrial premises in Puerto Rico. By understanding the features, benefits and technical parameters of different door bodies, customers can make decisions that best meet their needs. With the development of intelligence and automation. The industrial doors of the future will be more efficient and secure. Providing solid protection for the industrial development of Puerto Rico.