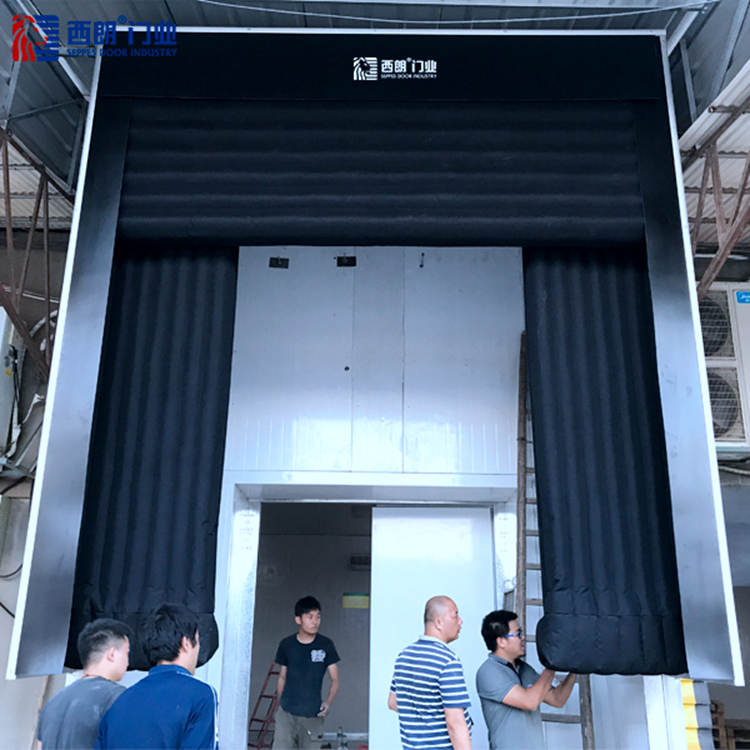

Mechanical Dock Shelter

The mechanical dock shelter curtains are made of double-layered polish bonded elastic strength fabric mechanically coated with PVC.

The side wings are fitted with reflective yellow guiding strips. The frame is hinged, and is designed to resist crushing.” It comprises a cover, bottom beam, and elastic linkage. The full cover is galvanized as a rust preventative, while the bottom beam and elastic linkage is anodized. The result is both beauty and modesty.

SEPPES: Your Premier Manufacturer Of Dock Shelter

SEPPES is a leading manufacturer of Mechanical dock shelters, committed to providing exceptional products that enhance efficiency and security in various industries. Drawing inspiration from cutting-edge technology, we consistently deliver reliable and innovative door solutions.

Core technology of Mechanical Dock Shelter

1. Strength

2.Sealing

3. Flexibility

4. Insulation

5. Protection

Mechanical Dock Shelter Data sheet

Product Name | Mechanical Dock Shelter |

Feature | Suitable more truck |

Function | High-sealing and high-insulation objects between the truck and the door frame |

Size(mm) | W 3400 x H 3400(customized according to customer requirements) |

Thickness of door curtain(mm) | 3(optional) |

Color | Black(RAL9017) |

Material | Polyester fabric |

Max Extended Force | 250 N/mm2 |

Friction Coefficient of Metal | 0.3 |

Friction Coefficient of PVC | 0.4 |

Diameter of Door Axis (mm) | 25 |

Unit Weight | 3.6kg/m2 |

Get A Quick Quotation Today

Applications of Mechanical Dock Shelter

Mechanical dock shelters deliver reliable, energy-efficient sealing that enhances loading and unloading efficiency in warehouses, manufacturing plants, and distribution centers—just a few examples. Thanks to durable fabric materials, flexible mechanical structures, and excellent adaptability to various vehicle sizes, these shelters ensure protection against wind, dust, and temperature loss during loading operations. They stand out especially within the application zones listed below.

Leading Mechanical Dock Shelter Manufacturers in China - SEPPES

Our company SEPPES is a professional Industrial Doors manufacturer. Products exported to 70 countries. Our products have multiple technical patents and EU CE certification with rich experience in fast shutter doors, rapid doors, high-speed roll-up doors, high-speed spiral doors, high-speed stacking doors, and PVC roller doors.

Why Choose Us

Here are 4 main reasons why many foreign buyers wholesale mechanical dock shelter from SEPPES Factory in China, along with fair data parameters for each point:

Competitive total cost and scalable capacity

Reference: US$690–1,399 per unit depending on type/MOQ on Made-in-China listings; factory area ~20,000 m² enabling fast production and large orders.

Broad specs, customization, and durability

Reference: Mechanical curtain thickness 0.9 mm PVC-coated polyester; frame galvanized with anodized aluminum trims; frequency of use ≥1,000 cycles/day; typical size W×H 3400×3400 mm (customizable).

Energy-saving, sealing, and safety performance

Reference: Best-seal designs to minimize energy loss; friction coefficient of PVC ~0.4; max extended force 250 N/mm²; warning reflective strips and drainage-inclined top frame.

Export credibility, certifications, and global proof

Reference: CE, SGS, UL certifications; 4,200+ partners across 70+ countries; Fortune 500 references cited; documented projects in Poland, Thailand, Malaysia.

Other Types of Loading Dock Equipment You May Like

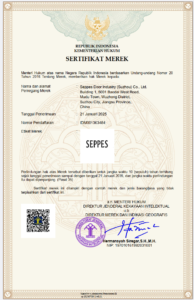

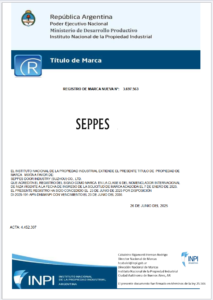

SEPPES International Trademark Certification

Since our founding, SEPPES has secured trademark registrations across several countries. Each new certification symbolizes growing worldwide recognition of our brand, which, in turn, reinforces our competitive position and expands our influence in international markets.

Welcome to SEPPES's Indsutrial Doors Factories

Frequently Ask Questions

Q What is a mechanical dock shelter?

A:A mechanical dock shelter is used on load doors to create a seal with a backing trailer. It features protective fabric curtains on a rigid frame which reduces weather, pests and contaminants while minimizing energy loss.

Q:What are the key components of a mechanical dock shelter?

A:A mechanical dock shelter constitutes a rigid head frame, vertical side curtains, two side curtains, a head cou; and is primarily composed of industrial-grade, galvanized weatherout curtains aided with steel and Aluminum framing for ductibility.

Q:How does a mechanical dock shelter differ from a dock seal?

A:Unlike a dock seal with pad foams that can slightly restrict an opening due to trailer backing, which is only beneficial to a uniform fleet, a mechanical shelter allows banner access to trailer without restriction while fully sealing the perimeter.

Q:How is a mechanical shelter different from an inflatable shelter?

A:Weighted curtains of mechanical frames provide set access without seal power, while inflatable frames with powered bladders seal to provide a tighter perimeter, though needing the most upkeep.

Q:What are the primary benefits of using a mechanical dock shelter?

A:The benefits encompass a reduced loss of energy from heating or cooling and an overall decrease in weather-related damage to merchandise, improved comfort and safety for employees, and enhanced protection of inventory. Furthermore, they promote hygiene by blocking the entrance of dust, debris, and pests.

Q:What are the typical dimensions of a mechanical dock shelter?

A:The standard size for dock shelters is designed for door openings from 8 feet wide by 8 feet high to 10 feet wide and 10 feet high. The overall structure is generally about 11 to 12 feet in width and 11 to 12 feet in height, with wall protrusions from 18 to 36 inches to accommodate a variety of dock bumpers.

Q:Can a mechanical dock shelter accommodate different trailer sizes?

A:Absolutely, this is one of the primary benefits. The flexible curtain construction enables servicing for a variety of trailer heights and widths, making them well-suited for facilities with diverse receiving vehicles.

Q: What materials are used to construct a mechanical dock shelter?

A:The curtains are composed of high tear strength, encapsulated PVC coated polyester or vinyl fabrics, and the equipment is framed using pressure-treated lumber, or galvanized steel, or extruded aluminum for corrosion and impact resistance.

Q: How effective is the seal created by a mechanical dock shelter?

A:A well specified shelter provides a good seal around the top and sides of a trailer. While not as airtight seal as an inflatable shelter, it is still quite effective in preventing the majority of wind, rain, and snow. This makes it a practical option for most general warehousing and distribution activities.

Q:How well do mechanical shelters resist wind, rain, and snow?

A:It likely is of an extremely weather resistant construction. Most of the fabric is waterproof and some designs have the top edge sloped to encourage drainage off the curtain to prevent the curtain from flapping. Some designs have features styled as wind stays or stiffeners in the side sheers to maintain the closure in windy conditions.