In modern industrial production, the efficient operation and safety management of the workshop is the key to ensure the smooth running of production. High Speed Industrial Doors as the ideal choice for workshop entrance doors. With its excellent performance and multi-functional applications, to enhance production efficiency, to ensure workshop safety plays an important role. In this article, we will discuss in detail the characteristics and advantages of High Speed Industrial Doors and their specific applications in workshop entrances.

What is a high speed industrial door?

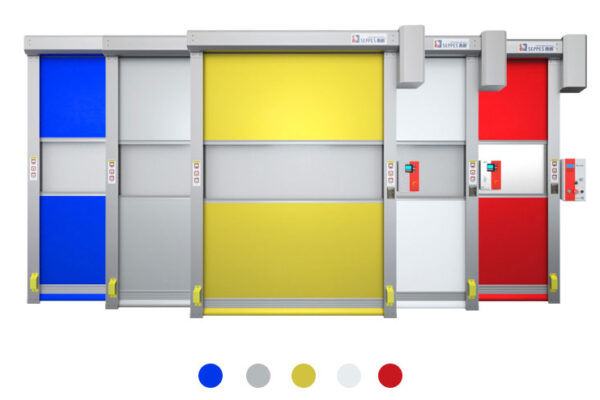

High speed industrial door is a kind of fast opening and closing door body with electric control system. Which is mainly made of high-strength material with fast opening and closing, high frequency use and excellent sealing performance. According to different application requirements. High-speed industrial doors can be divided into high speed rolling door, Fabric Roll Up Door and High Speed Coiling Door and other types.

Application advantages of high speed industrial door

Efficient switching: the switching speed of high speed door is usually about 1-2 meters per second. Which can significantly reduce the waiting time of workshop personnel and equipment, and improve logistics and production efficiency.

High safety performance: high-speed industrial doors are equipped with a variety of safety devices. Such as safety light curtains, fall prevention devices and emergency stop buttons, etc.. Which can effectively prevent accidents from occurring and protect the safety of workshop personnel and equipment.

Excellent sealing performance: High-speed industrial doors have good sealing performance. Which can effectively prevent dust, odor and interference from the external environment and keep the internal environment of the workshop clean and stable.

Strong durability: High-speed industrial doors are made of high-strength materials and precision manufacturing process. With excellent durability and impact resistance, and can maintain good performance for a long time under frequent use.

Multi-functional application: High-speed industrial doors are suitable for a variety of industrial places. Not only can be used as the entrance door of the workshop, but also widely used in warehouses, logistics centers, clean rooms and cold chain logistics and other fields.

How to choose the right high speed industrial door?

When choosing high speed PVC doors, enterprises should consider the following factors according to their specific needs and application scenarios:

Door body material: choose high-strength, durable materials, such as high-strength steel plate. Aluminum alloy and special fabrics to ensure the durability and impact resistance of the door body.

Switching speed: according to the logistics requirements of the workshop, choose the appropriate switching speed to enhance operational efficiency.

Safety devices: choose high speed doors equipped with multiple safety devices. Such as safety light curtains, fall prevention devices, etc., to protect the safety of personnel and equipment.

Sealing performance: According to the environmental control needs of the workshop, choose the high-speed industrial door with excellent sealing performance to keep the internal environment clean and stable.

Comparison of high speed industrial door with other door

Compared to Fabric Roll Up Doors: Fabric roll up doors are typically used in locations. That require a high level of environmental cleanliness and good sealing performance. High-speed industrial doors on the other hand, have more advantages in terms of opening and closing speed and durability, and are suitable for a wider range of industrial applications.

Compared with the High Speed Coiling Door: High-speed winding door also has the ability of fast opening and closing and high-frequency use. But high-speed industrial doors in the structural design and safety performance is more prominent, suitable for places that require high strength and durability.

Compared with ordinary industrial doors: ordinary industrial doors usually have slower opening and closing speeds. That cannot meet the needs of high-frequency use, while high speed industrial doors have fast opening and closing speeds and multiple safety devices. That can significantly improve production efficiency and safety management.

Prospect of high speed industrial doors in the workshop entrance

With the increasing demand for modern industrial production and logistics, efficient and safe workshop entrance doors have become an important facility for enterprises to enhance their competitiveness. With its excellent performance and multi-functional applications. High speed fabric doors play an irreplaceable role in enhancing production efficiency and ensuring workshop safety. In the future, with the continuous progress of technology and the growth of market demand. The application of high speed doors in the workshop entrance will have a broader future.

Summarize

As an ideal choice for workshop entrance, Seppes high-speed industrial door significantly improves production efficiency and safety management level by virtue of its advantages of fast switching. High-frequency use and multiple safety devices. Through the combined use with fabric rolling doors, high-speed winding doors and other door bodies. High speed rubber doors can meet the needs of different industrial places, optimize the production process. And enhance the economic benefits of enterprises. Enterprises in the purchase of high speed coiling doors, should be comprehensive consideration of the door body material, switching speed and safety devices and other factors. Choose the product that suits their needs, to provide a solid guarantee for efficient production and safety management.