卡车约束系统

Truck Restrictor Product Introduction

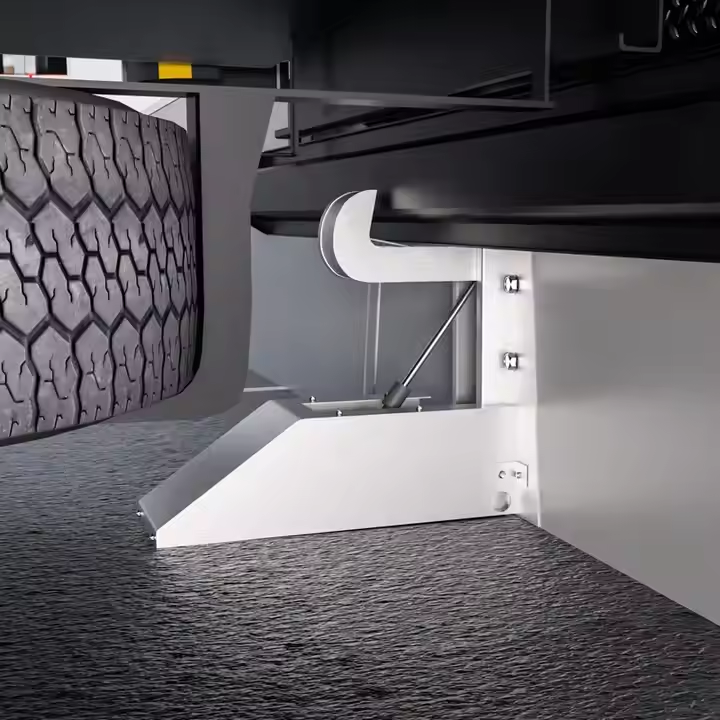

Vertical Lift Truck Restrictor

The Vertical Lift Limiter is floor-mounted. The limiting device is operated by a control box installed indoors, and the vertical limiting hook pulls the truck’s anti-collision tailgate and fixes it to the loading/unloading platform.

SEPPES: Your Premier Manufacturer Of Truck Restraint System

SEPPES is a leading manufacturer of high-quality, Vertical Lift Truck Restrictors committed to providing exceptional products that enhance efficiency and security in various industries. Drawing inspiration from cutting-edge technology, we consistently deliver reliable and innovative door solutions.

创新技术

- Self-developed, designed and produced

- Simple and reliable structure, only need to do routine lubrication and maintenance on the axle

- Maximum lifting up to 254mm, applicable to a wide range of truck types

- Hydraulic drive enables the hook body to maintain continuous following and fixing of the truck when the height of the truck changes

- Galvanized coating inside and out and can be painted with warning colors

- Audible warning device

- Internally mounted control box and externally mounted signaling system

Components of the truck limited motion system

Mechanical locking assembly, made from a steel base, protects all components from damage due to weather, dust, and debris.

a. Stable operation even in harsh environments, and the advantages of simple operation and maintenance.

b.The limiting mechanism can withstand a maximum pulling force of 14.5 tons.

Self-developed control system.

a.High brightness LED traffic signal design for universal red and green lights.

b.The equipment uses PLC (Programmable Logic Controller) for system control, which effectively enhances the accurate and reliable operation of the equipment and enables interconnection and interlocking with other platform equipment.

c. When loading and unloading goods, the reliable design follows with the rise of the car.

Signal cueing system

1. LED lights are standard, LED lights have a long service life, and the voltage is powered by safe voltage (DC 24 volts).

2. LED indicator lights are used at the buttons to increase the degree of recognition of the operation and prevent misoperation in the dark environment.

3. External Signal Light System: Flashing red or green light all the time to prompt the truck driver whether it is safe to reverse into or out of the highway traffic lights with the same level of design as a bright waterproof low-voltage signal light system.

4. Internal Signal System: Flashing red or green light all the time to indicate whether the freight platform operator can safely carry out loading and unloading operations.

5. The internal signaling system flashes the opposite of the external signaling system.

6. AUDIO ALARM: An internal alarm device alerts the platform operator that the truck tailgate is not in its normal restricted position.

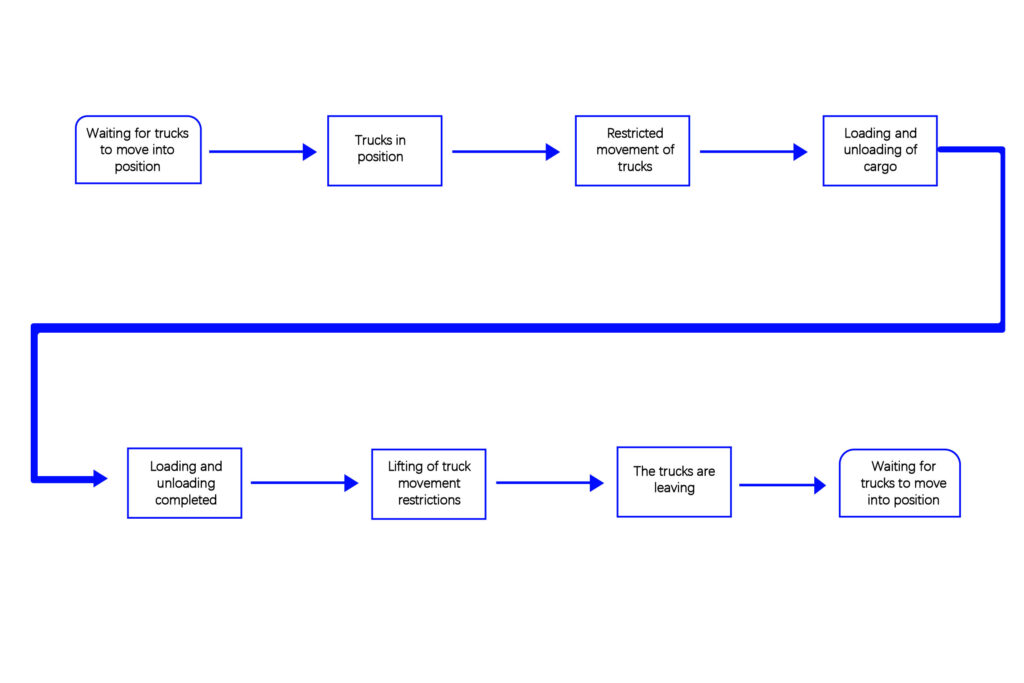

Truck Restrictor Workflow Description

1. When the truck is backed into the loading platform, the platform staff presses the locking button on the control panel to lift the limiter and secure the truck.

2. The LED indicator shows inner green/outer red, and the van is limited to moving. And it can withstand a pulling force of over 14.5 tons.

3. The limiter stays in contact with the crash bar and is automatically adjusted by the float of the truck to ensure that it is always effectively limiting during the loading/unloading operation.

4. When loading/unloading is complete, the platform operator presses the unlock button on the control panel to unlock the truck.

5. The LED signal light system will automatically adjust to the outer green/inner red traffic signal indication.

立即获取快速报价

公司简介

赛普拉斯门业(苏州)有限公司 是一家专注于工业门技术开发、设计和制造的高科技公司,总部位于中国苏州。我们为工业客户量身定制完整的入口门系统解决方案。我们的主要产品包括高速门、自动卷帘门、分节门等。所有产品均符合欧洲工业标准,并已获得以下认证 欧盟 CE国际 SGS和 ISO9001 质量管理体系。认证。

凭借专业的产品和品牌声誉,SEPPES 已成为一家合作企业。 60 多家财富 500 强企业的供应商.产品有 出口到超过 50 个国家和地区 我们已为包括欧盟、澳大利亚、美国、加拿大、法国、日本、迪拜和俄罗斯在内的 3,200 多家企业客户提供了产品和技术解决方案以及多重产品安全保障!

根据图纸进行定制设计

了解需求

Prior to the start of the project, we will understand in detail the specific needs of the client for the high-speed doors, including the environment of use, functional requirements and, budget.

定制解决方案

在明确客户需求后,我们的专业设计团队会根据实际情况定制设计方案,并绘制详细图纸。

设计图纸

我们的设计考虑到了高速门的功能性、美观性和安全性。客户可以在此阶段对设计提出任何修改意见,以确保最终解决方案完全符合预期。

高效制造

一旦设计图纸得到客户确认,我们的生产部门将立即开始生产。我们拥有先进的生产设备和工艺技术,确保每一扇快速门都符合最高标准。在生产过程中,我们严格控制每一个环节,确保产品质量和交货期。

安全包装和运输

产品生产出来后,我们会进行严密包装,确保产品在运输过程中不受损害。我们与专业物流公司合作,确保产品能准时、安全地送达客户指定地点。

从下单到生产大约需要 18 个工作日。

满意度反馈

安装完成后,我们会邀请客户对我们的产品和服务进行评估。我们非常重视客户的反馈意见,并将其用于不断改进我们的产品和服务。我们的许多客户都称赞我们的高性能快速门在节能和提高生产率方面表现出色。

哥伦比亚客户

物流公司: "自从安装了 SEPPES 的高速门之后,我们的仓库运营得到了极大的改善。这些门的高性能和可靠性大大缩短了货物进出的时间,提高了客户满意度。

东南亚客户

电子厂: "SEPPES 的高速门非常适合我们的电子生产车间。该门的快速开关功能有助于我们保持车间温度恒定,确保产品质量。

澳大利亚客户

矿业公司: "SEPPES 的高速门在我们的采矿设施中发挥了重要作用。这种门的高耐用性和快速反应能力有助于在恶劣的环境中保持较高的运行效率"。

俄罗斯客户

制造工厂: "在我们位于俄罗斯的制造厂,SEPPES 的高速门大大提高了我们的生产效率。即使在寒冷的环境中,这种门的高性能和可靠性也表现出色"。

我们拥有真实权威的证书

我们了不起的客户

We have exported to more than 65 countries and regions. Our powerful service internet and install team helps us build relationships with customers who come from Europe, Middle East, South America, and South East Asia.

中国领先的高速雷达电机制造商和供应商

SEPPES 致力于为您的企业提供各种类型的高速门传感器。

您可能喜欢的其他类型产品

The Ultimate Guide to Truck Restraint System

A Truck Restraint System is a critical safety feature in loading docks that secures trucks during the loading and unloading process. By preventing unintended movement, these systems enhance the safety of workers and protect cargo. This guide covers everything you need to know about truck restraint systems, including their functions, benefits, and key considerations for installation.

What is a Truck Restraint System?

- 定义和目的

- Overview of how it works

Types of Truck Restraint Systems

- Mechanical Restraints: Description and features

- Hydraulic Restraints: How they operate

- Electronic Restraints: Advantages of smart technology

主要优势

- 加强安全: Prevents truck movement during operations

- Reduced Risk of Accidents: Protects workers and cargo

- 提高效率: Streamlines loading and unloading processes

- 耐用性: Built to withstand harsh industrial environments

Applications of Truck Restraint Systems

- 仓库

- Distribution centers

- Manufacturing facilities

- 装卸码头

Choosing the Right Truck Restraint System

- Factors to consider (type, weight capacity, features)

- 关于 SEPPES 产品的建议

FAQ for Truck Restraint System

Q1: What is a truck restraint system?

A1: A truck restraint system is a safety device that secures trucks in place during loading and unloading to prevent unintended movement.

Q2: How does a truck restraint system work?

A2: It typically involves mechanical, hydraulic, or electronic components that engage with the truck’s chassis to hold it securely in position.

Q3: What are the benefits of using a truck restraint system?

A3: Benefits include enhanced safety for workers, reduced risk of accidents, improved loading efficiency, and protection of cargo.

Q4: Where can truck restraint systems be used?

A4: They are commonly used in warehouses, distribution centers, manufacturing facilities, and loading docks.

Q5: How is a truck restraint system installed?

A5: Installation involves assessing the site for optimal placement and integrating the system with existing loading dock equipment, often requiring professional assistance.

Q6: What maintenance is required for a truck restraint system?

A6: Regular inspections and maintenance are necessary to ensure proper operation, including checking for wear and tear on components.