Uruguay’s Industrial Development Drives Increased Demand for Industrial Doors

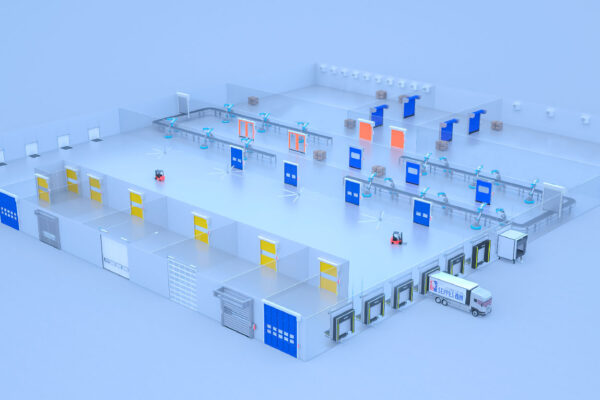

In recent years, as Uruguay’s logistics and transportation, cold chain warehousing, food processing, port construction, and industrial manufacturing and other fields continue to develop, enterprises in the plant and warehouse access management system have put forward higher requirements. Industrial doors, as basic but key equipment, gradually moved from the traditional “open and close the door” function to the“energy saving, safety, efficiency” multi-functional direction of evolution.

For companies looking for a long-term investment, choosing a set of Uruguay industrial door suitable for Uruguay’s climate and usage scenarios will significantly improve operational efficiency, reduce energy consumption, and enhance security control.

Uruguay Industrial Doors Market Status and Trends

Market Drivers

Growth in demand for warehousing and handling facilities driven by the construction of ports and free trade zones (e.g., Port of Montevideo);

Growth in cold chain logistics: Uruguay is an important exporter of meat and dairy products in Latin America. With strong demand for thermostatic door bodies;

Food processing and pharmaceutical industry growth driving procurement of clean, high-frequency, and secure door types;

Green building policies encouraging energy-efficient industrial doors to replace older products.

Key Market Trends

High-speed opening and closing doors gradually replace manual rolling doors;

Rising demand for industrial doors focusing on wind protection, corrosion prevention, and heat insulation in coastal and harbor areas;

Automation and remote control door systems have become the focus of project bidding.

Uruguay mainstream industrial door types and applicable scenes

As Uruguay’s industrial modernization process continues to accelerate, especially in the areas of cold chain warehousing, port logistics, and food processing. And automated manufacturing, the performance of industrial doors is gradually increasing. The following are some of the most widely used types of industrial doors in the Uruguayan market today, each of which is suitable for specific scenarios and has its unique advantages:

Hochgeschwindigkeits-Rolltor

High-Speed Roll Up Door is a kind of industrial door with a PVC flexible door curtain as the main material, supporting high-frequency rapid opening and closing (opening speed of up to 1.5-2.0m/s), with good dust-proof, insect-proof, and energy-saving effects, suitable for indoor and outdoor frequent passage areas. It is particularly common in Uruguay’s food processing plants, sorting centers. And workshop transition areas, and is especially suited to industrial sites pursuing efficiency and cleanliness due to its fast, efficient, and sealed nature.

Insulated Sectional Door

This kind of door adopts a polyurethane foam door plate, the thickness is generally 40-50mm. With excellent heat insulation and thermal insulation ability, suitable for refrigerated truck rooms, constant temperature logistics warehouses, harbor frozen goods warehouses, and other places. It supports a variety of opening methods and is suitable for different doorway heights and structural forms.

High-Speed Spiral Door

This kind of door has both a rigid structure and high-speed running characteristics. The door plate is made of aluminum alloy, with wind pressure resistance, beautiful and generous, and almost no friction noise in the running process. Suitable for automobile manufacturing, electronic factories, and laboratories. And other places, especially suitable for enterprises with high requirements for image, frequency, and safety.

Aluminium-Rolltor

The door is made of corrosion-resistant aluminum alloy, simple appearance, cost-effective, suitable for projects with moderate protection performance requirements and sensitive budgets, such as port loading and unloading ports, warehouse doors, commercial workshops, etc., with flexible operation methods and convenient installation.

High Speed Freezer Door

High-speed door specially designed for a low-temperature cold storage environment. With a double curtain structure and heating system to prevent condensation and icing, to ensure the sealing performance of the entrance and exit, and to reduce the loss of cold air. Commonly used in -30°C to 0°C environment in the frozen goods logistics warehouse, meat processing plants. And cold chain distribution centers, is to improve energy efficiency and access to the key equipment.

High-Speed Zipper Door

Self-repairing doors can automatically reset after a collision or derailment, reducing manual intervention and downtime. And are suitable for high-frequency access areas. It is especially suitable for clean areas, forklift lanes, refrigerated buffer rooms, etc., where high safety and operational reliability are required.

Comparison table of industrial door types and application scenarios in Uruguay

| Industrial door types | Hauptmerkmale | Typical Application Scenarios |

| Hochgeschwindigkeits-Rolltor | Fast opening and closing, dustproof and insect-proof, automatic control | Food processing, warehousing and logistics, factory access |

| Insulated Sectional Doors | PU door panel, good heat insulation, high wind resistance level | Cold chain warehousing, distribution centers, port frozen goods warehouse |

| Spiral hard fast door | Rigid panel, modern appearance, quiet operation | High-end manufacturing, electronics factory, clean workshop |

| Aluminium-Rollladen | Lightweight, corrosion-resistant, moderate cost, suitable for medium-sized doorways | Commercial warehouses, loading and unloading ports, maintenance workshops |

| Cold Storage Fast Door | Double-layer structure, anti-icing, built-in heating function, extreme temperature resistance | Freezers, meat processing plants, -30°C preservation environment |

| Self-repairing Fast Door | Automatic reset, anti-impact, highly sealed | Clean aisles, buffer zones, logistics transfer exits |

Selection advice: how to choose the right industrial door for the Uruguayan environment?

When selecting a model, it should be evaluated based on the following key factors:

Climatic environment: Coastal cities need to choose corrosion-resistant structures (such as aluminum alloy, stainless steel). Indoor cold areas need to focus on thermal insulation performance.

Industry Scenario:

Cold chain and food industry → Thermal insulation door + high-speed door

Logistics sorting and warehouse → high-speed rolling door + automatic control system

Pharmaceutical and dust-free environment → high sealing self-repairing high-speed door

Operation Frequency: High frequency use is recommended to use durable motor + intelligent control system.

Certification requirements: CE, ISO9001, EN 1634 (fire protection) and other certifications to improve engineering compliance.

Sourcing & Supplier Selection Guide

Local vs Imported

| Projects | Local sourcing | Imported suppliers (e.g. China, Europe) |

| Kostenstruktur | Higher costs, fewer options | Advantageous price, full range, support OEM customization |

| Installation Services | Fast local service | Need to cooperate with drawings and video guidance, some with local agent support |

| Compliance Certification | Most meet basic standards | Can provide complete CE/ISO certification information to support project bidding |

| Accessory Supply | Fast response | Remote supply or reserve spare parts package |

Recommendations for selection

Work with a professional industrial door manufacturer that has export experience and offers multi-language support (Spanish/English);

Check if they support customized sizes, voltage specifications, intelligent control modules;

Check whether they provide installation drawings, technical manuals, remote video guidance services.

Maintenance and Service Life Extension Recommendations

In order to guarantee the long-term stable operation of the equipment. It is recommended that enterprises establish the following maintenance mechanism:

Monthly checking of tracks, drive systems, button controllers;

Quarterly cleaning of door curtains/panels, anti-corrosion coatings;

Semi-annual replacement of seals, lubrication of chains, testing of safety devices;

High-frequency areas are recommended to set up safety photoelectricity, motor overheating protection system.

Good maintenance can extend the service life of industrial doors to 10-15 years, significantly reducing long-term operation and maintenance costs.

Conclusion: Choosing the right Uruguay industrial door to build efficient and safe industrial facilities

The Uruguay industrial door market is at a critical stage of upgrading and transformation. And selection criteria are increasingly aligned with international standards. Whether it’s a cold chain food company, an automated logistics center, or a port project, choosing Uruguay industrial doors products that meet the performance, certification, and installation support is a key part of achieving long-term energy efficiency and safe operation.

FAQ (Häufig gestellte Fragen)

1. What are the most common types of industrial doors in Uruguay?

Common types include high-speed rolling doors, insulated lift doors, cold storage fast doors, spiral rigid doors and aluminum alloy rolling doors for logistics, cold chain, manufacturing and other industries.

2. How to choose the right industrial door for my factory?

According to the temperature and humidity environment, the size of the door opening, the frequency of use, and the security needs of a comprehensive assessment is required. It is recommended to consult a professional supplier in conjunction with the type of industry.

3. Do industrial doors comply with Uruguayan import and use standards?

It is recommended to choose industrial doors with CE, ISO or EN certificates in order to meet the compliance and safety requirements of the project.

4. Is remote installation or technical guidance supported?

Yes, exporting manufacturers usually provide installation videos, technical drawings, and remote guidance services. And some also support technical documentation in Spanish.