Opportunities and Challenges in the Global and Regional Landscape of 2025

The global economic and geopolitical landscape will continue to evolve in 2025. China’s Belt and Road Initiative will be further promoted, Russia’s energy and trade relations with the European Union (EU) will continue to adjust, and tariff policies among Eurasian Economic Union (EAEU) member states will become more integrated. Against this backdrop, Kazakhstan, strategically located at the crossroads of Europe and Asia and developing major hub ports such as Almaty and Khorgos, is accelerating its transformation into a regional logistics and manufacturing center, driving rising demand for Kazakhstan Industrial Door solutions that meet the highest standards of durability and safety.

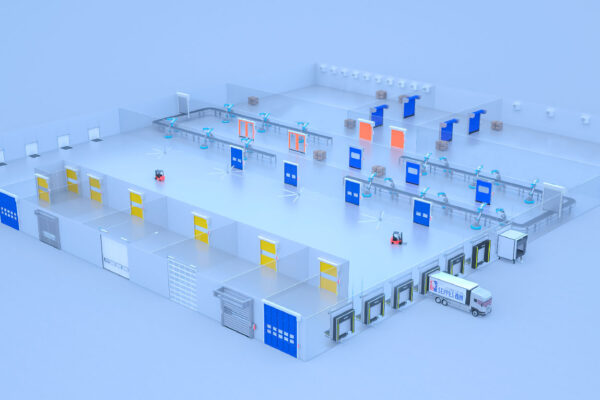

Against this backdrop, Kazakhstan industrial door market has seen unprecedented growth opportunities – on the one hand, the downstream oil and gas, mining, cold chain, modern logistics and other industries have seen a surge in demand for high-performance industrial doors; on the other hand, stringent international and local standards, cross-border trade policies, and cost control pressures also On the other hand, strict international and local standards, cross-border trade policies and cost control pressure have put forward higher requirements for buyers and suppliers. This article will help you grasp the procurement and application of industrial doors in Kazakhstan from market insight, product selection, compliance certification, international trade, supplier strategy, to installation and maintenance under the new situation.

Kazakhstan Industrial Door Market Overview

Industry Size and Growth Forecast

The Kazakhstan industrial door market is expected to grow at a compound annual growth rate (CAGR) of 8-10% during 2020-2025.

Key downstream applications: oilfield logistics corridors (~30%), large-scale mining plants (20%), cold chain warehousing and food processing industry (25%), modern logistics centers (15%), and others (10%).

Local Production vs Import Dependence

Kazakhstan industrial door production is mostly undertaken by small and medium-sized enterprises, the products to simple rolling doors, storage doors, production capacity accounting for about 20% of the market.

The remaining 80% of the demand relies on imports, the main source countries in the following order: China (about 45%), Russia (20%), Belarus (5%), Germany/Italy (5%), other (5%).

Market pain points

Extreme climate: as low as -40°C in winter and as high as +40°C in summer, testing door materials, seals, and drive systems.

High standard demand: dustproof, explosion-proof, fireproof, heat insulation, wind pressure resistance level up to 8-10.

Logistics and customs clearance efficiency: multinational procurement needs to deal with multiple customs declarations, VAT and EAC certification processes, increasing the delivery time and cost risks.

Main Industrial Door Types and Application Scenarios

高速卷帘门

典型应用 oilfield logistics transit, chemical plant area isolation channel.

Core parameters: opening and closing speed of 1.5-2.0 m/s, high sealing PVC or reinforced polyester curtain; wind pressure level up to 6-8.

Advantages and disadvantages: fast response, energy saving and dust reduction, but the impact resistance is lower than that of metal door panels.

分节式顶门

典型应用 cold chain warehousing, food processing plants, modern logistics centers.

Core parameters: door thickness 40-50mm (PU foam filling), thermal insulation thermal conductivity ≤ 0.35 W / (m²-K); wind pressure 8-10 level;

Advantages and disadvantages: excellent thermal and acoustic insulation and wind resistance, modular design for easy maintenance, but slower opening and closing speed (0.2-0.3 m/s).

Explosion-Proof Industrial Doors

典型应用 chemical plants, pipeline maintenance areas, and flammable and explosive materials warehouses.

Core parameters: ATEX/IECEx standards, explosion-proof electric control box, non-sparking motors, sealing grade up to IP66;

Advantages and disadvantages: high safety, harsh explosion-proof certification, relatively high cost, and maintenance.

Fire-Rated Industrial Doors (Fire-Rated Doors)

典型应用 power plants, research laboratories, multi-storey garages.

Core parameters: fire resistance 60-120 minutes (EN 1634, UL 10C certification); smoke sealing strip, automatic closing device;

Advantages and disadvantages: meets the needs of life safety and security, but the door plate is heavy, opening and closing need special drive and buffer mechanism.

Special customized doors (Cold-Room Doors / Sandblasting Doors etc.)

Cold Room Doors: Stable opening and closing at low temperature (-40°C), filling density ≥ 48 kg/m³;

Sandblasting room doors: inner layer with PVC protective curtain and anti-abrasive coating; high-strength steel outer layer;

Advantages and disadvantages: highly targeted and flexible maintenance cycles, but longer design and certification cycles.

Below are the five main types of industrial doors commonly found on the Kazakhstan market, along with their typical applications, core technical parameters and key advantages, and finally optional replacement options.

Main Industrial Door types and application scenarios

| Door type | Typical Applications | Core parameters | 主要优势 | Alternative Solutions |

| High Speed Roll Up Door | Oilfield logistics corridor, chemical plant isolation | Opening and closing speed 1.5-2.0 m/s; wind pressure resistance class 6-8; curtain material PVC/reinforced polyester; sealing strip EPDM | Fast opening and closing, energy saving and dust reduction | Sectional Door: For higher thermal insulation and wind resistance, foam board sectional door can be used |

| Industrial Overhead Doors | Cold chain storage, food processing, modern logistics center | Door thickness 40-50 mm (45 kg/m³ PU foam); thermal conductivity ≤ 0.35 W/(m²-K); wind pressure 8-10 level; speed 0.2-0.3 m/s | Insulation, sound insulation, strong wind pressure resistance; modularization and easy maintenance | High Speed Rolling Door: For fast opening and closing, combine a high speed curtain with an insulating curtain. |

| Explosion-proof industrial doors | Chemical plants, pipeline maintenance areas | ATEX/IECEx; explosion-proof electric control box; non-sparking motor; IP66 protection class | High safety, explosion-proof certification | Sectional Overhead Door with explosion-proof kit |

| 防火工业门 | Power plants, laboratories, multi-story garages | Fire-resistant 60-120 min (EN 1634/UL 10C); smoke-proof sealing strip; automatic closing mechanism | Delay the spread of fire, to protect the safety of personnel | Fireproof rapid door: faster opening and closing with the same level of fire-resistant performance |

| Customized Specialized Doors(Cold Room / Sandblast | Cold storage, sand blasting room | Refrigerated door: -40 °C operation; sheet 48 kg/m³ PU foamSandblasted door: PVC anti-abrasive curtain + high-strength steel plate + anti-abrasive coating | Targeted protection, low temperature/impact resistance | High-speed rolling door + PVC curtain: fast isolation/anti-friction |

Latest Standards and Compliance Requirements for 2025

International Standards

ISO 9001 (Quality Management) and ISO 14001 (Environmental Management) as basic quality and environmental requirements;

CE marking (EU safety standard), UL certification (US safety standard) and EN 13241 (EU standard for external influences on industrial doors).

Regional/Local Standards

GOST R: Kazakhstan follows the Russian GOST series of mandatory standards covering materials, construction and fire protection.

EAC Certification (EAEU Mark of Conformity): Harmonized certification of product safety and environmental requirements for Eurasian Economic Union member states.

Certification process

Laboratory testing: door panel corrosion resistance, fire resistance, wind pressure resistance and other items;

Third party inspection: EAC/CE organization on-site audit and factory audit;

Documentation cycle: It takes about 8-12 weeks to prepare and test the whole set of documents.

Updated for 2025

The Eurasian Economic Union has harmonized and updated the energy efficiency classification of electronic control systems to a minimum of IE2;

The new EN standard for fire doors strengthens the requirements for flame retardant materials for smoke seals and passages near the door.

International Trade and Tariff Policy Implications

EAEU Tariff Preferences

Products from China, Russia, Belarus and other member countries enjoy zero or less than 5% import tariffs;

Preferential policies significantly reduce the cost advantage of Chinese manufacturers in the Kazakhstan market.

Logistics Advantages under Belt and Road

China-European liner: Alashankou-Khorgos line shortens transportation time up to 10-14 days;

Port synergy: Aktu port-Khorgos multimodal transportation and increasingly simplified customs clearance procedures.

Sanctions and trade barriers

Sanctions against some Russian companies affected the supply of machinery and equipment parts, requiring the deployment of alternative supply chains;

Frequent document review delays in non-EU customs clearance for European equipment.

Tariffs and cost sensitivity

Import tariffs: about 5-15% for products from non-EAEU countries;

Value Added Tax (VAT): 12%-14%;

Combined transportation, customs clearance and warehousing costs can account for 10-12% of the overall value of the shipment and need to be included in the total cost of ownership (TCO) analysis.

Supplier Selection and Sourcing Strategies

Local vs International Comparison

| Dimension | Local suppliers | International suppliers |

| Product Categories | Mostly standardized products, limited customization | Complete types, support multi-level customization |

| Certification Compliance | GOST/EAC certification, short lead time | CE/UL/EN standards, high-end certifications |

| 成本结构 | No tariffs, higher unit price | Low manufacturing cost with tariffs |

| 准备时间 | Delivery within 2-4 weeks | 30-40 days for sea transportation, 10-14 days for land transportation |

Advantages of Chinese suppliers

Price advantage: even after accounting for low tariffs, manufacturing in China is still 20-30% lower than in Europe and the United States;

Customization capability: from materials to drive systems and seal forms can be configured on demand;

Certification support: most manufacturers can provide a full set of certification documents such as EAC, CE, ISO, etc.

Advantages of European/American products

Leading technology: airtight protection, motor life and intelligent control system are more mature;

After-sales service: global service network, timely response, localized support available.

Negotiation and contractual points

Price sharing model: compare the cost of FOB, CIF and DDP;

Warranty and wearing parts: clarification of warranty period, spare parts supply cycle and cost;

Payment methods: L/C, T/T, D/P, etc. risk and cost balance.

Installation, Maintenance & Lifecycle Cost Management

安装前准备

Door opening measurement: accurate to ±5mm, reserved safety clearance;

Foundation pre-embedding: track and electric control box location and power distribution pre-embedding;

Environmental docking: dustproof, anti-corrosion and temperature control needs synchronization confirmation.

定期维护

Monthly inspection: track cleaning, pulley lubrication;

Quarterly maintenance: motor and explosion-proof component testing, airbag inflation check;

Annual major maintenance: seal replacement, fire/explosion protection system integrity check.

Troubleshooting and recovery

Common faults: door body jamming, motor overheating, seal leakage;

Rapid recovery: standardized spare parts kit + remote technical support, recovery time ≤ 24 hours.

Life Cycle Cost Modeling

Initial Purchase Cost + Transportation & Customs + Installation + Annual Maintenance + Energy Consumption = Total Cost of Ownership (TCO);

It is recommended that model comparisons be determined by TCO rather than a single price.

Conclusion and Outlook

Under the latest international situation and policy environment in 2025, the sourcing and application of industrial door in Kazakhstan will need to take into account compliance and certification, supply chain diversification, and life cycle cost optimization.

Key insights: EAEU tariff preferences and China-EU liner logistics advantages open up a win-win situation for Chinese suppliers in terms of cost and timeliness.

Future Trends: Intelligent industrial doors (IoT monitoring, self-diagnosis), green and energy-saving materials, and modular structure will become mainstream;

Suggestions for action: dynamically update the standard library, build regional spare parts centers, establish long-term cooperation with suppliers, and carry out localized technical training to achieve sustainable competitiveness.

常见问题

What are the main tariff rates for importing industrial door into Kazakhstan?

Customs duties are around 5-15% for non-EAEU countries and 12-14% for VAT.

How can I be sure that the products I choose comply with EAC and CE standards?

Ask for EAC/CE certificates, lab reports and factory audits when purchasing.

How to ensure the sealing performance of the door at -40°C?

Choose low-temperature elastic EPDM seals and conduct on-site nitrogen filling or cold resistance test.

What terms should I focus on when negotiating an import contract?

Pricing terms (FOB/CIF/DDP), warranty and spare parts supply terms, lead times and breach of contract.

How to evaluate the Total Cost of Ownership (TCO) of an industrial door?

Comprehensive formula: Initial cost + Transportation/customs clearance + Installation + Maintenance + Energy consumption, recommended to be analyzed in comparison with the budget model.