Industrial sectional doors play a vital role in optimizing facility operations. Their space-efficient design ensures seamless integration into various industrial environments, enhancing productivity and safety. These doors provide exceptional durability and energy efficiency, making them ideal for businesses aiming to reduce maintenance costs and improve environmental control. With quick opening and closing mechanisms, they streamline workflows and bolster security measures. Selecting the right industrial sectional door not only safeguards assets but also contributes to long-term operational success.

Key Takeaways

Assess your facility’s unique needs to ensure the industrial sectional door aligns with operational goals and enhances efficiency.

Choose a door type that matches your specific industry requirements, such as quick-opening mechanisms for high-traffic areas or superior insulation for temperature-sensitive environments.

Prioritize durability by selecting materials like galvanized steel that can withstand heavy use and harsh weather conditions.

Evaluate insulation properties and R-values to enhance energy efficiency and reduce operational costs.

Consider customization options for size, color, and features to ensure the door fits seamlessly into your facility’s design and operational needs.

Invest in professional installation to guarantee optimal performance and longevity of the door, minimizing future maintenance issues.

Seek expert advice from manufacturers to make informed decisions and leverage warranties for peace of mind regarding your investment.

Assess Your Facility’s Requirements

Choosing the right industrial sectional door begins with a thorough assessment of your facility’s unique needs. Each business operates differently, and understanding these specific requirements ensures the door aligns with operational goals and enhances efficiency.

Understand operational needs and traffic flow

Facilities must evaluate their daily operations to determine how the door will integrate into workflows. High-traffic areas, such as loading docks or workshop entrances, require doors that open and close quickly to maintain productivity. For example, businesses in manufacturing or logistics often benefit from doors with advanced operating systems that support frequent use. Additionally, the direction and volume of traffic—whether pedestrian or vehicular—should influence the choice of door design and functionality.

Evaluate environmental factors like temperature and humidity

Environmental conditions play a critical role in selecting an industrial sectional door. Facilities located in regions with extreme temperatures or high humidity levels need doors with superior insulation and sealing capabilities. Proper insulation not only helps regulate indoor temperatures but also reduces energy costs. For instance, doors equipped with high-density polyurethane foam panels provide excellent thermal resistance, making them ideal for temperature-sensitive environments like food processing plants or cold storage facilities.

Determine the size and frequency of door usage

The size of the door opening and its frequency of use are essential considerations. Large facilities, such as warehouses or automotive repair shops, often require oversized doors to accommodate vehicles or equipment. Frequent usage demands durable materials and robust mechanisms to withstand wear and tear. Selecting a door tailored to these specifications ensures long-term reliability and minimizes maintenance needs. Businesses should also consider the potential for future expansion when determining door dimensions.

Understand Door Types and Their Applications

Selecting the right industrial sectional door requires understanding the various types available and their specific features. Each type serves unique purposes, making it essential to match the door to the facility’s operational demands.

Overview of industrial sectional door types and their features

Industrial sectional doors come in a variety of designs, each tailored to meet different industrial needs. These doors consist of multiple panels connected by hinges, allowing them to rise vertically and retract horizontally. This design optimizes space, making them ideal for facilities with limited room for door operation.

Manufacturers often construct these doors using durable materials like steel, aluminum, or other metal alloys. These materials enhance wind resistance and ensure the doors can withstand harsh environmental conditions. Additionally, many industrial sectional doors feature advanced operating systems, such as torsion spring mechanisms and frequency conversion controls, which improve efficiency and ease of use.

Match door types to specific facility needs and industries

Different industries require doors that align with their unique operational requirements. For example:

Warehouses: Facilities with high traffic often benefit from sectional doors with quick opening and closing mechanisms to maintain workflow efficiency. For example: – Food Processing Plants: Doors with superior insulation and sealing capabilities help regulate temperature and maintain hygiene standards.

Automotive Repair Shops: Oversized sectional doors accommodate large vehicles and equipment, ensuring smooth operations.

Matching the door type to the facility’s specific needs ensures optimal performance and long-term reliability.

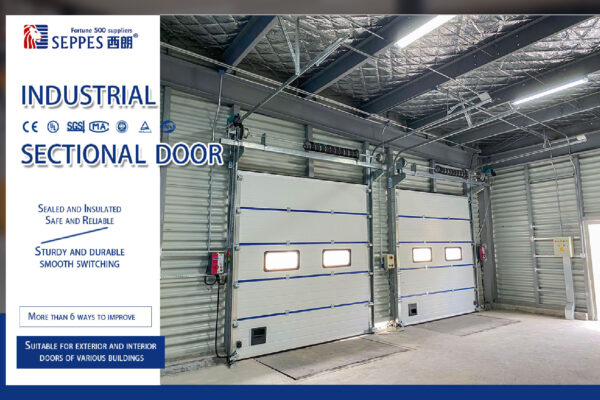

Consider SEPPES Industrial Sectional Door’s versatility for indoor and outdoor use

The SEPPES Industrial Sectional Door offers unmatched versatility, making it suitable for both indoor and outdoor applications. Its space-efficient design allows seamless integration into various environments, from manufacturing plants to logistics centers. The robust 40 mm thick high-density polyurethane foam panel provides exceptional thermal insulation, ensuring energy efficiency in temperature-sensitive settings.

This door also features advanced safety mechanisms, including finger protection and cable break protection, which enhance operational safety. Its customizable options, such as size, color, and finish, allow businesses to tailor the door to their specific requirements. Whether used in a cold storage facility or a busy loading dock, the SEPPES Industrial Sectional Door delivers functionality, durability, and style.

Evaluate Insulation and Energy Efficiency

Energy efficiency plays a crucial role in industrial operations, and the right door can significantly impact a facility’s energy efficiency.

Importance of thermal insulation for energy savings

Thermal insulation is essential for maintaining a consistent indoor temperature. Insulated doors help prevent heat transfer, ensuring that heating or cooling systems operate efficiently. This reduces energy consumption and lowers utility bills. According to studies, insulated doors contribute to a more sustainable operation by minimizing greenhouse gas emissions. Facilities in temperature-sensitive industries, such as food processing or pharmaceuticals, benefit greatly from doors with superior insulation. These doors help protect products and maintain compliance with industry standards.

Assess the R-value and sealing capabilities of the door

Proper sealing is equally important. Doors with advanced sealing mechanisms prevent air leakage, further enhancing saving energy.

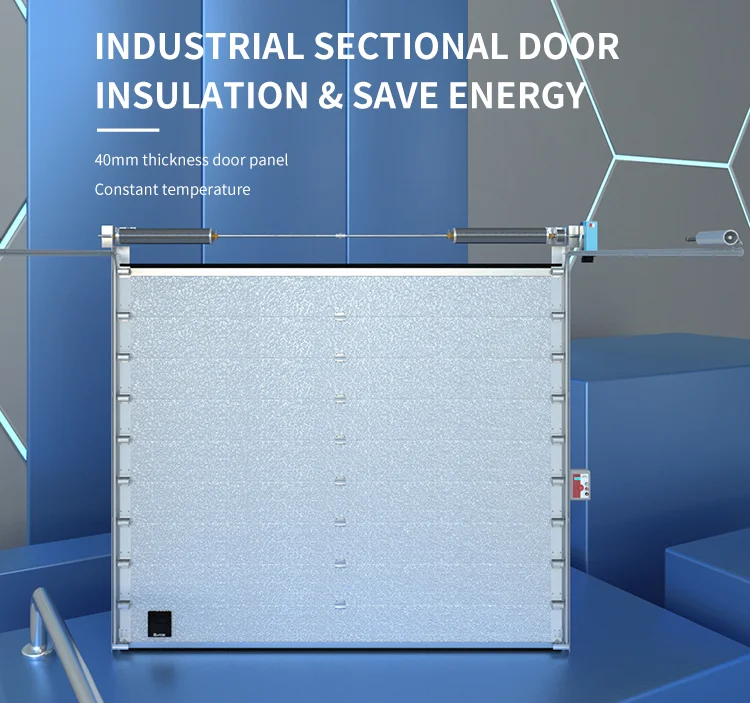

Highlight SEPPES Industrial Sectional Door’s high-density polyurethane foam panel

The SEPPES Industrial Sectional Door exemplifies energy efficiency with its 40 mm thick high-density polyurethane foam panel. This advanced material provides exceptional thermal insulation, making it ideal for facilities requiring precise temperature regulation. The door’s design minimizes heat transfer, reducing heating and cooling costs. Additionally, its sealing capabilities ensure airtight performance, preventing energy loss. Businesses can rely on this door to create a more sustainable and cost-effective operation. By combining durability, functionality, and energy efficiency, the SEPPES Industrial Sectional Door stands out as a top choice for modern industrial facilities.

Consider Customization Options

Customization plays a pivotal role in ensuring that an industrial sectional door meets the unique demands of a facility.

Explore size, color, and design flexibility

Industrial facilities often require doors that fit specific dimensions to optimize space usage. Custom-sized doors adapt precisely to the available space, ensuring a perfect fit for non-standard openings. This flexibility proves essential for facilities with unique architectural designs or operational needs.

Color and design customization also allow businesses to align the door’s appearance with their branding or aesthetic preferences. For instance, a facility can choose bold colors to reflect its corporate identity or opt for neutral tones to maintain a professional look. Design flexibility ensures that the door not only serves its functional purpose but also complements the overall visual appeal of the facility.

Choose materials and finishes that align with your facility’s needs

The choice of materials significantly impacts the door’s durability and performance. Facilities operating in harsh environments often benefit from doors constructed with galvanized steel or aluminum, which resist wear and tear effectively. For industries requiring enhanced hygiene, such as food processing, smooth and easy-to-clean finishes are ideal.

Finishes also play a crucial role in enhancing the door’s longevity. Coatings that resist corrosion or UV damage ensure the door remains functional and visually appealing over time. By selecting materials and finishes tailored to their specific requirements, businesses can maximize the door’s lifespan and efficiency.

Incorporate additional features like automation and safety enhancements

Modern industrial sectional doors offer advanced features that improve convenience and safety. Automation, such as frequency conversion intelligent control systems, allows for smooth and efficient operation. Automated doors reduce manual effort, speeding up workflows in high-traffic areas.

Safety enhancements, including finger protection and cable break protection, safeguard employees during door operation. These features minimize the risk of accidents, creating a safer work environment. Facilities can also integrate wind resistance capabilities to ensure reliable performance in adverse weather conditions. By incorporating these additional features, businesses enhance both operational efficiency and workplace safety.

Prioritize Durability and Maintenance

Select materials designed for heavy-duty use, such as galvanized steel

Durability remains a critical factor when selecting an industrial sectional door. Materials like galvanized steel offer exceptional strength and longevity, making them ideal for heavy-duty applications. Steel doors resist deformation caused by environmental changes, ensuring consistent performance in various conditions. Their robust construction makes them suitable for high-traffic areas, such as workshops and loading docks, where frequent use demands reliable durability.

Galvanized steel doors also undergo a powder coating process, which enhances their resistance to corrosion, aging, and fading. This coating ensures the door maintains its structural integrity and appearance over time, even in harsh environments. Businesses operating in industries like manufacturing or logistics often prefer steel doors for their ability to withstand wear and tear while providing long-term value.

Evaluate resistance to wear, tear, and weather conditions

Industrial facilities often expose doors to challenging conditions, including heavy usage and extreme weather. Doors must resist wear and tear to maintain functionality and reduce maintenance costs. Steel-framed doors outperform many alternatives due to their superior strength and resilience. They endure repeated opening and closing cycles without compromising performance, making them a dependable choice for busy facilities.

Weather resistance is equally important. Steel doors do not expand or contract with temperature fluctuations, ensuring smooth operation in all climates. Their ability to withstand wind, rain, and UV exposure makes them suitable for both indoor and outdoor applications. Facilities in regions with severe weather conditions benefit from doors designed to handle these challenges without frequent repairs or replacements.

Highlight SEPPES Industrial Sectional Door’s safety features and ease of maintenance

The SEPPES Industrial Sectional Door exemplifies durability and ease of maintenance. Its construction includes a 40 mm thick high-density polyurethane foam panel, which enhances collision resistance and thermal insulation. This design ensures the door performs reliably in demanding industrial environments. The use of galvanized steel in its frame further strengthens its ability to resist wear, tear, and weather-related damage.

Safety features, such as finger protection and cable break protection, prioritize employee well-being during operation. These mechanisms reduce the risk of accidents, creating a safer workplace. Additionally, the door’s advanced operating system minimizes maintenance requirements. Components like the torsion spring tension balance and pulley sliding rail ensure smooth and efficient operation, reducing the need for frequent servicing.

Businesses can rely on the SEPPES Industrial Sectional Door for its combination of durability, safety, and low maintenance. Its robust design and innovative features make it a valuable investment for facilities seeking long-term reliability and operational efficiency.

Factor in Space and Installation Needs

Assess available space for door operation and installation

Industrial facilities must evaluate the available space to ensure the sectional door operates efficiently. The door’s vertical movement requires sufficient headroom and side clearance. Facilities with limited space benefit from sectional doors due to their compact design, which maximizes usable floor area. Measuring the dimensions of the installation site accurately helps avoid operational issues later.

For example, facilities with low ceilings may require doors with specialized lifting mechanisms. These mechanisms allow the door to function smoothly without obstructing other equipment or workflows. Proper space assessment ensures the door integrates seamlessly into the facility’s layout, enhancing both functionality and safety.

Understand mounting and floor requirements for proper fit

Mounting and floor conditions significantly impact the performance of industrial sectional doors. The mounting surface must be sturdy enough to support the door’s weight and withstand frequent use. Walls made of reinforced materials, such as concrete or steel, provide a reliable foundation for installation. Weak or uneven surfaces may compromise the door’s stability and lead to operational inefficiencies.

The floor beneath the door also plays a crucial role. A level and smooth surface ensures the door seals properly when closed, preventing air leakage and maintaining energy efficiency. Facilities should inspect the floor for irregularities and address any issues before installation. Understanding these requirements helps businesses achieve a secure and precise fit, reducing the likelihood of future maintenance needs.

Plan for long-term operational efficiency with professional installation

Professional installation ensures the industrial sectional door operates safely and efficiently over time. Certified technicians follow industry standards and use specialized tools to install the door correctly. This minimizes the risk of errors that could lead to malfunctions or safety hazards. Proper installation also enhances the door’s durability, allowing it to withstand heavy usage and environmental challenges.

“Proper installation is crucial for the long-term performance of commercial doors.” Hiring professionals guarantees adherence to safety standards and optimal functionality.

Additionally, professional installers often provide valuable advice on maintenance practices. Regular inspections and prompt repairs prevent minor issues from escalating into costly problems. Facilities that invest in professional installation benefit from long-term reliability and reduced operational disruptions.

Seek Professional Advice and Support

Selecting the right industrial sectional door involves more than just choosing a product. Professional advice and support ensure that businesses make informed decisions and achieve optimal performance from their investment. Experts provide valuable insights, proper installation, and ongoing assistance to enhance the door’s functionality and longevity.

Consult with industry experts or manufacturers like SEPPES

Industry experts and manufacturers possess in-depth knowledge about industrial sectional doors. Consulting with them helps businesses identify the most suitable door for their specific needs. Professionals analyze factors such as operational requirements, environmental conditions, and safety standards to recommend the best solution.

“Reputable brands like Hörmann and SEPPES offer high-quality industrial doors recognized for security and durability.”

Manufacturers like SEPPES also provide detailed information about their products’ features and benefits. For instance, SEPPES offers advanced safety mechanisms, including airbags and emergency handbrake devices, which enhance protection during operation. Engaging with experts ensures that businesses select a door that aligns with their operational goals and safety priorities.

Ensure proper installation by certified professionals

Proper installation is critical for the efficient operation of an industrial sectional door. Certified professionals possess the skills, tools, and experience required to install doors accurately. They follow industry standards to ensure the door operates smoothly and safely.

Professional installers also address specific requirements, such as mounting surfaces and floor conditions, to guarantee a secure fit. For example, they inspect walls and floors to ensure they can support the door’s weight and maintain its stability. By relying on certified professionals, businesses reduce the risk of installation errors that could lead to malfunctions or safety hazards.

“Experts can install airbags and emergency handbrake devices at the bottom of the door to ensure optimal protection.”

Additionally, professional installation enhances the door’s durability. Properly installed doors withstand heavy usage and environmental challenges, minimizing the need for frequent repairs. Businesses benefit from long-term reliability and reduced operational disruptions.

Leverage warranties and after-sales support for peace of mind

Warranties and after-sales support provide businesses with confidence in their investment. Manufacturers like SEPPES offer comprehensive warranties that cover potential defects or issues. These warranties ensure that businesses receive prompt assistance if problems arise, reducing downtime and repair costs.

After-sales support includes services such as maintenance, repairs, and technical guidance. Professional service providers diagnose and resolve issues accurately, ensuring the door continues to perform efficiently. Regular maintenance by experts prevents minor problems from escalating into costly repairs.

“Professional services ensure that repairs and maintenance are done correctly and safely.”

By leveraging warranties and after-sales support, businesses gain peace of mind knowing that their industrial sectional door remains in optimal condition. This proactive approach enhances operational efficiency and extends the door’s lifespan.

Selecting the best industrial sectional door requires careful consideration of several factors. Evaluating facility needs ensures the door aligns with operational demands. Prioritizing durability guarantees long-term performance in challenging environments. Seeking professional guidance simplifies the decision-making process and ensures proper installation. These steps help businesses achieve efficiency, safety, and cost savings. The SEPPES Industrial Sectional Door offers a perfect blend of functionality, safety, and style, making it an excellent choice for modern facilities. By following these tips, businesses can make informed decisions that enhance their operations.

FAQ

What are the characteristics of industrial sectional doors?

Industrial sectional doors feature multiple panels, also known as sections, connected by hinges. This design allows the door to rise vertically and retract horizontally, making it ideal for facilities with limited space. These doors are typically constructed from durable materials like steel, aluminum, or other metal alloys, ensuring excellent wind resistance and protection. Their robust build enables them to withstand harsh environmental conditions, providing long-lasting performance in industrial sectional doors settings.

What are the main types of commercial overhead doors?

Commercial overhead doors come in various types, including sectional doors, rolling doors, and high-speed doors. Sectional doors stand out for their space-efficient design and versatility. They are widely used in garages, warehouses, and other industrial applications due to their durability and ease of operation. These doors are distributed through direct and indirect channels, catering to diverse business needs.

How do industrial sectional doors enhance energy efficiency?

Industrial sectional doors contribute to energy efficiency through superior insulation and sealing capabilities. Features like high-density polyurethane foam panels minimize heat transfer, helping facilities maintain consistent indoor temperatures. Proper sealing prevents air leakage, reducing the strain on HVAC systems and lowering energy costs. These attributes make sectional doors an excellent choice for temperature-sensitive environments.

What safety features should businesses look for in industrial sectional doors?

Safety is a critical consideration when selecting industrial sectional doors. Key features include finger protection, cable break protection, and spring break protection. These mechanisms reduce the risk of accidents during operation, ensuring a safer workplace. Advanced safety enhancements, such as emergency handbrake devices, further enhance protection and operational reliability.

Can industrial sectional doors be customized?

Yes, industrial sectional doors offer extensive customization options. Businesses can tailor the size, color, and design to meet specific requirements. Materials and finishes can also be selected based on operational needs, such as galvanized steel for durability or smooth finishes for hygiene-sensitive industries. Additional features like automation and wind resistance can be incorporated to enhance functionality.

What factors should businesses consider when choosing an industrial sectional door?

When selecting an industrial sectional door, businesses should evaluate their facility’s operational needs, environmental conditions, and space constraints. Durability, insulation properties, and safety features are also essential considerations. Professional advice and proper installation ensure the door meets long-term operational demands effectively.

How do sectional doors differ from rolling doors?

Sectional doors consist of multiple panels that rise vertically and retract horizontally, optimizing space usage. Rolling doors, on the other hand, roll up into a compact coil above the opening. While sectional doors provide better insulation and customization options, rolling doors are often preferred for their simplicity and suitability in high-traffic areas.

Are industrial sectional doors suitable for outdoor use?

Yes, industrial sectional doors are designed for both indoor and outdoor applications. Their durable construction and weather-resistant materials make them suitable for various environments. Features like wind resistance and corrosion-resistant finishes ensure reliable performance in outdoor settings.

How can businesses ensure proper installation of industrial sectional doors?

Proper installation requires certified professionals who follow industry standards. They assess mounting surfaces, floor conditions, and space requirements to ensure a secure fit. Professional installation enhances the door’s durability and operational efficiency, reducing the likelihood of malfunctions or safety hazards.

Why should businesses choose SEPPES Industrial Sectional Doors?

SEPPES Industrial Sectional Doors combine functionality, safety, and style. Their advanced features, such as high-density polyurethane foam panels and robust safety mechanisms, ensure energy efficiency and workplace safety. Customization options allow businesses to tailor the doors to their specific needs. With a reputation for quality and innovation, SEPPES provides reliable solutions for modern industrial facilities.