Machine Protection Door

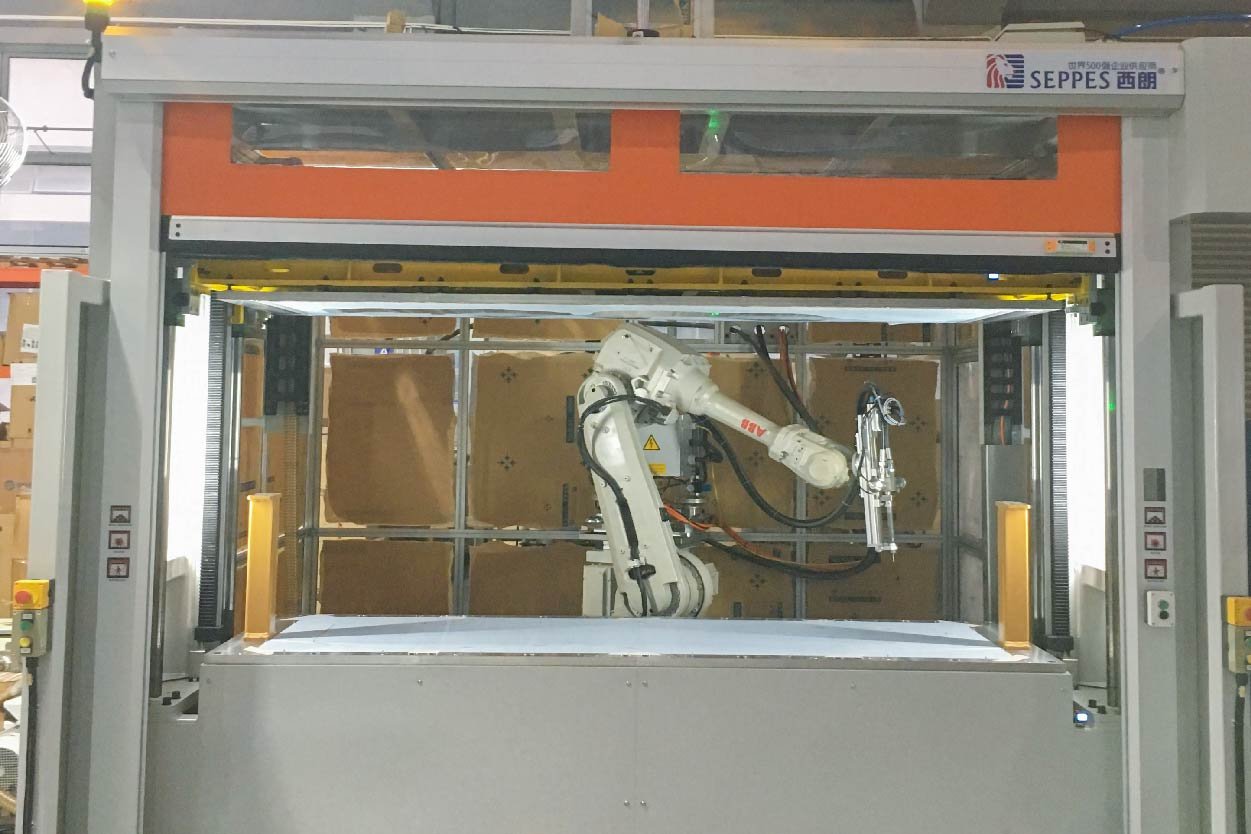

In any industry, Machine Protection Doors (MPDs) are essential for safety and productivity, as they protect against hazards and debris, and provide clear passageways for operators. Their applications are prevalent in manufacturing, welding, and any form of automation.

MPDs by SEPPES Door are renowned for rapid deploy time, and rugged builds which minimize accidents and increase productivity. Doors are customizable to specific requirements and industry regulations.

SEPPES: Your Premier Manufacturer Of Safe High-Speed Door

SEPPES is a leading manufacturer of high-quality high-speed PVC rapid roller doors, committed to providing exceptional products that enhance efficiency and security in various industries. Drawing inspiration from cutting-edge technology, we consistently deliver reliable and innovative door solutions.

Core Technology Of Machine Protection Door

1.Stability

2.Security

3. Protection

4. Visibility

5. Reliability

Machine Protection speed door

| Specification | Description |

|---|---|

| Product | Machine Protection Door |

| Material | 2 mm high-strength steel or 3 mm aluminum |

| Opening Speed | Adjustable, 0.5-2.5 m/s |

| Closing Speed | Adjustable, 0.3-1.0 m/s |

| Width | 1,000 – 6,000 mm (customizable) |

| Height | 1,000 – 6,000 mm (customizable) |

| Applications | Manufacturing, robotic welding, laser processing |

| Compliance | ISO 12100, ISO 14119, ISO 13849 |

| Operating Temp. | -10°C to 50°C |

| Safety Features | Emergency stop, integrated safety light curtains |

Get A Quick Quotation Today

Applications of Machine Protection Door

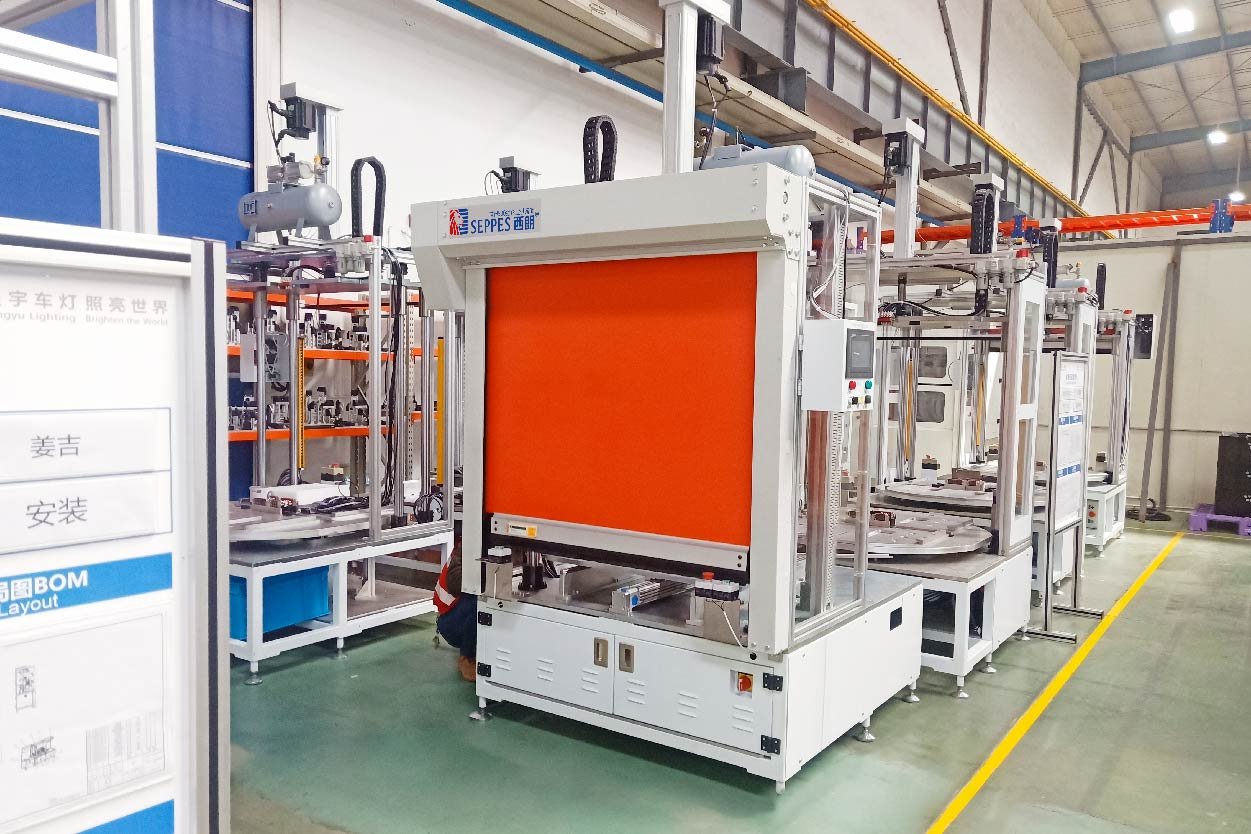

Machine protection doors deliver fast, reliable access that enhances safety and efficiency around automated production lines, robotic cells, and industrial machinery—just a few examples. Thanks to high-speed operation, robust safety sensors, and durable materials, these doors provide secure separation between operators and moving equipment while maintaining workflow continuity. They stand out especially within the application zones listed below.

Leading Hydraulic Dock Leveler Manufacturers in China - SEPPES

Our company SEPPES is a professional Industrial Doors manufacturer. Products exported to 70 countries. Our products have multiple technical patents and EU CE certification with rich experience in fast shutter doors, rapid doors, high-speed roll-up doors, high-speed spiral doors, high-speed stacking doors, and PVC roller doors.

Why Choose Us

Here are 4 main reasons why many foreign buyers wholesale machine protection door from SEPPES Factory in China, along with fair data parameters for each point:

Compliance, safety, and performance

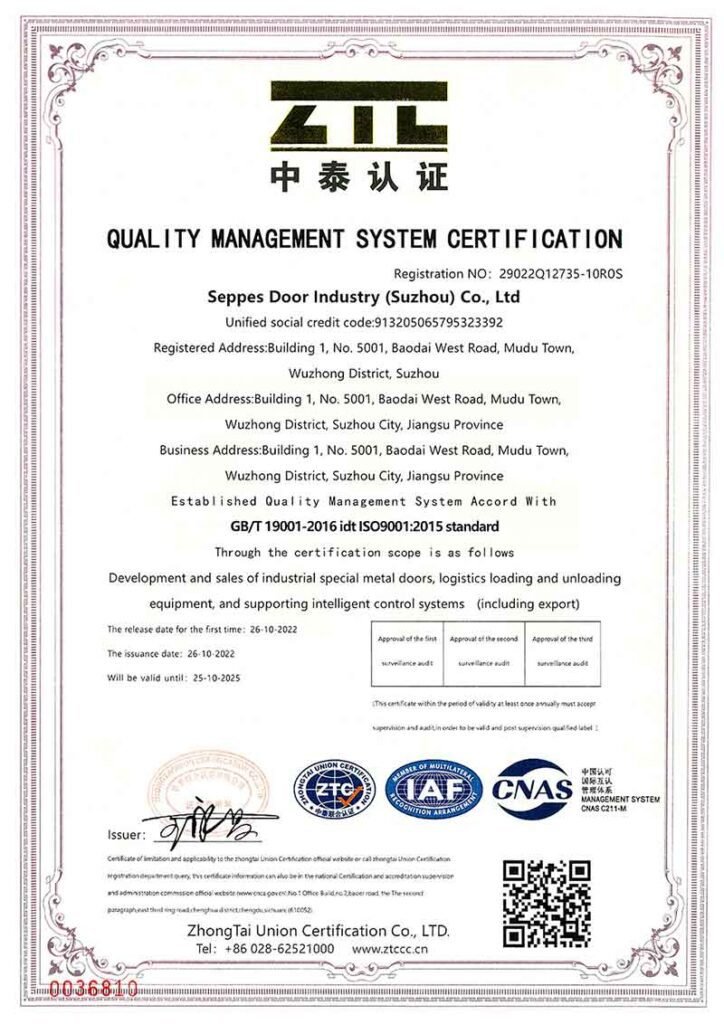

Certifications: CE, ISO9001, SGS (factory claims) 5 Opening speed: 1.5–2.0 m/s typical for machine protection doors 3 Safety options: light curtain, safety bottom edge/airbag sensors 3 Ingress protection: up to IP54 on certain models

Durable, high‑cycle engineering

Curtain thickness: up to 2.0 mm for protection models 3 Cycle life: 1.0–1.5+ million cycles (servo systems) 5 Frame options: aluminum alloy or 304 stainless steel 35 Warranty: commonly 12–13 months (manufacturer stated)

Customization and application fit

Speed range: ~0.8–2.0 m/s adjustable 5 Sizes/colors: RAL color options; width/height tailored 35 Opening methods: radar, loop detector, pull‑switch, wireless, remote, Bluetooth 3 Specialized variants: welding/robot cells, cleanrooms, refrigeration

Global delivery capability and value

Export footprint: 60–70+ countries served (manufacturer stated) 35 Lead time: ~10–30 days depending on order (factory guidance) 3 Pricing reference (zipper/cleanroom doors): roughly $1,150–$1,690 per unit wholesale, with volume discounts (manufacturer stated) 5 Client base: 3,600–3,800+ customers; partnerships with well-known brands (manufacturer stated)

Other Types of Industrial Doors You May Like

Our Amazing Clients

We have exported to more than 65 countries and regions. Our powerful service internet and installation team helps us build relationships with customers who come from European, the Middle East, South America, and South East Asia.

We have authentic and authoritative certificates

Welcome to SEPPES's Indsutrial Doors Factories

Frequently Ask Questions

Q:What is a machine protection door?

A:A machine protection door functions autonomously as a high-speed safety barrier aimed at robot cells, automats, and production line along with the inner machinery. Thus, they help achieve minimum cycle time while keeping a worker armless in an operational zone and separated from robot arms, improving productivity and safety on the line.

Q:What are the key benefits of using these doors?

A:Increased operational up time due to the high automation witnessed and also worker safety improvement, as the machineries are cloistered with a physical barrier at arm’s reach, balancing and enhancing productivity at the workstation. This also helps in controlling factors such as welding spatter and dust, as well as helps reduce footprint in light curtain applications.

Q: What safety features are typically included?

A:Intrinsic safety precautions include the immediate retracting and halting functions of the machine, if it detects an obstruction, due to safety sensors such as light curtains and infrared photo eyes. Many come with the feature of a soft flexible edge to lower the contact impact, and machine control locking to the door, such that machine movement initiates only with the door closed.

Q:How fast are machine protection doors and what is their typical lifespan?

A:The minimum cycle time is 60 seconds, at an opening velocity of 2.5 m/s, with a subsequent 2 minute pause which is optimal in production to save time on entire cycle time. These doors are capable to 1 million working cycles if maintained properly and are equipped with great servo motors, which helps extend the overall functionality of the machine.

Q:What materials and thickness are used for the door curtain?

A:Curtains are typically fabricated from tear and impact resistant PVC, usually between 1.2mm to 2.0mm thick. For certain applications, like welding cells, the fabric can be arc flash and slag resistant, as well as flame resistant.

Q:Can machine protection doors be customized for size and specific needs?

A:Yes, these doors are almost always built to order to match specific dimensions and application needs. This can include a variety of RAL colors, translucent window patches for sight lines, and a variety of curtain materials to suit special industrial needs.

Q:How do these doors integrate with existing automation and control systems?

A:Machine protection doors are designed to work with PLCs and robotic controllers. They usually have numerous I/O ports and can be wired to the machine’s safety circuit for automatic opening, closing, and emergency stop control.

Q: What kind of maintenance is required?

A:Routine maintenance usually consists of inspections of safety sensors, curtain tension and condition, and track sensors. Components are made to endure high cycles, but reliability inspections are needed to assure performance.

Q: What industry certifications or compliance standards should I look for?

A:When selecting doors, pay attention to any applicable international safety standards regarding safety guarding. CE certifications for the European area around health and safety and environmental protection, as well as others depending on the region, are also applicable.

Q:What is the typical cost and lead time?

A:Prices depend on size, speed, motor type, and additional safety features, hence a quote is inevitable. The typical delivery and manufacturing deadlines depend on the level of customization and the particular manufacturer, ranging from a few weeks and to a few months.