スポンジ・ドック・シェルター

スポンジドックシェルターカーテン生地は、表面にPVCコーティングを施したポリエステル繊維弾性強度生地で作られています。内部には最大圧縮率75%の高弾性スポンジが充填されています。生地はネジと金属グロメットで固定されており、圧力がかかっても常に均等に空気が溢れるようになっています。プリーツ加工されたページは、両側と上部に配され、耐摩耗性、押し出し防止加工が施されています。壁には耐力が必要です。

特徴より強固なシーリング保護;

SEPPES: ドックシェルターのプレミアサプライヤー

セッペス はスポンジドックシェルターのトップメーカーであり、様々な産業において効率性と安全性を高める優れた製品を提供することに尽力しています。最先端技術からインスピレーションを得て、信頼性の高い革新的なドアソリューションを一貫して提供しています。

スポンジドックシェルターのコア技術

1.柔軟性

2.レジリエンス

3.シーリング

4.適応性

5.効率性

Sponge Dock Shelter Dock Sheet

製品名 | SEPPES スポンジ・ドック・シェルター |

農産物直売所 | 中国製 |

機能 | 高気密・高断熱物 トラックとドアフレームの間 |

サイズ | 3.4X3.4Mはに従ってカスタマイズされる 顧客要件(固定トラックモデル) |

適切なトラック | コールドチェーントラック |

カラー | ブラック |

素材 | ポリ塩化ビニール生地+スポンジ |

クイック見積り

Applications of Sponge Dock Shelter

Sponge dock shelters deliver tight, energy-saving sealing that optimizes loading and unloading performance in warehouses, cold storage facilities, and logistics centers—just a few examples. Thanks to high-resilience sponge pads, wear-resistant PVC covers, and an excellent sealing effect against vehicle contours, these shelters effectively prevent air exchange, rain, and dust infiltration during docking operations. They stand out especially within the application zones listed below.

Resources on Mechanical Dock Seal

1.Explore The Best Options For Industrial Locations: Eight Features And Application Scenarios Of The Sponge Dock Shelter

選ばれる理由

Here are 4 main reasons why many foreign buyers wholesale sponge dock shelter from SEPPES Factory in China, along with fair data parameters for each point:

Proven global export capacity

Detail: Established export brand, broad market presence and after-sales support Reference: 65+ countries served; 3,600+ clients worldwide2 Fair parameter: Typical lead time 12–25 days for bulk orders; export share >70% of output (reference range for mature exporters)

Reliable product construction and materials

Detail: Durable curtain/panel materials and weather-resistant build for high-traffic docks Reference: Double-layer polyester fabric with PVC surface on panels; elastic-strength fabric design3 Fair parameter: Panel thickness 0.8–1.2 mm; PVC coating weight 600–900 g/m²; operating temp −20°C to 60°C

Risk control and assurance

Detail: Product liability coverage indicates quality confidence and third‑party underwriting Reference: Insurance underwritten by Ping An with RMB 15 million coverage1 Fair parameter: Warranty 12–24 months; defect rate <1% on outgoing QC; replacement window 7–15 days after claim approval

Competitive value amid growing market demand

Detail: Scale benefits from China manufacturing and rising global logistics investments Reference: Global dock shelter market estimated at about USD 1.28B in 2024, indicating healthy demand growth4 Fair parameter: FOB unit price range USD 380–780 per shelter for standard sponge models; annual capacity 5,000–15,000 units; volume discount tiers at 50/100/200+ units

その他のドック設備

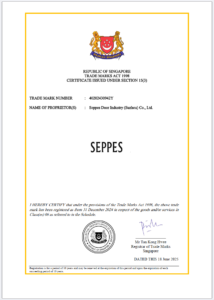

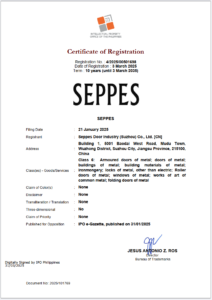

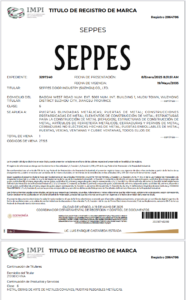

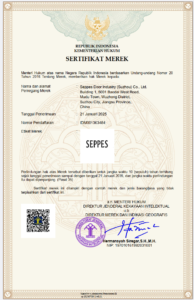

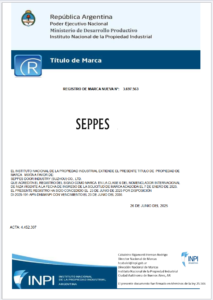

SEPPES International Trademark Certification

Since our founding, SEPPES has secured trademark registrations across several countries. Each new certification symbolizes growing worldwide recognition of our brand, which, in turn, reinforces our competitive position and expands our influence in international markets.

Welcome to SEPPES's Indsutrial Doors Factories

Frequently Ask Questions

Q What is a sponge dock shelter?

A:Foam dock shelters, or sponge dock shelters, utilize side pads which are foam-filled along with a head curtain or pad to seal off the opening of a loading dock to the back of a truck. This prevents the dock area from being exposed to elements, along with pest and temperature changes, while loading and unloading.

Q:How does a sponge dock shelter differ from a dock seal?

A:While both utilize foam, sponge dock shelters enable the truck to park within the perimeter of the shelter, allowing for full, unobstructed access to the trailer opening. A dock seal, on the other hand, requires the truck to “nose” up to the pads which slightly restrict access to the trailer’s interior.

Q:What's the difference between a sponge shelter and an inflatable shelter?

A:Dock sponge shelters use high density foam for passive and durable sealing protection, and deflated cubical shelters use a blower which requires power and has more moving parts.

Q:Can a sponge dock shelter accommodate different truck sizes?

A:Yes. They are designed to service a wide range of truck widths and heights. The flexible side and head components are capable of compressing and adapting to various trailer dimensions which makes them highly versatile.

Q:What are the typical dimensions for a sponge dock shelter?

A:Standard shelters are usually designed for dock openings of 8 ft x 10 ft or 9 ft x 10 ft in size. Due to their customizable nature, standard shelters can be modified to match customizable rough opening widths, with extensions usually varying between 18 and 30 inches.

Q:Do I need a dock leveler or bumpers with a sponge shelter?

A:Yes, sponge shelters are designed to be used with dock levelers and bumpers. The bumpers serve the important purpose of sustaining the sponge and building foundation from truck impacts.

Q:What materials are used to make a sponge dock shelter?

A:The pads are made with closed cell, high-density, polyurethane foam and are wrapped in a weather resistant PVC, polyester or vinyl protective coating. The sponge dock shelter frame is usually made from treated wood or galvanized steel.

Q: How well do sponge shelters resist wind and rain?

A:Sponge shelters are designed to seal the edges of a trailer in order to keep rain, snow, and wind from gaining entry. Many models are designed with curtains, draft dodgers, and other devices for the purpose of fending off drafts.

Q: What is the expected lifespan of a sponge dock shelter?

A:If used and serviced regularly, a sponge dock shelter is designed to last for 5 to 10 years plus. The lifespan of the sponge dock shelter however is determined by the number of trucks passing through as well as the weather.

Q:What are the installation requirements for a sponge shelter?

A:Unit installation needs a wall which is structurally sound and flush around the dock opening, with enough wall space to mount the side frames and the head unit. Primary measurements consist of the size of the dock opening, projection of the bumper, and what the grade of the approach driveway is.