In modern industrial environments, a door body is more than just a simple opening – it plays a vital role in improving efficiency, ensuring safety, and optimizing the use of space. With the ever-changing demands of production and warehousing, vertical lift sectional doors are becoming increasingly popular as an innovative door body solution for industrial facilities.

Vertical lift sectional doors are uniquely designed to maximize space savings, avoiding the lateral occupancy of traditional door bodies. And are particularly suited to environments with high ceilings and limited space. Not only do they provide efficient and secure access. But they also improve efficiency and reduce energy consumption, making them ideal for many modern businesses, warehouses, factories, and cold storage facilities.

What is a Vertical Lift Sectional Door?

The Vertical Lift Sectional Door is an advanced industrial door body designed for use in environments where space is limited and security and durability are important. Unlike traditional horizontal openings, vertical lift sectional doors have panels that lift vertically and the door body opens directly upwards without tilting. This design not only saves space but also efficiently provides easy access to buildings and warehouses.

Typically used for high ceilings and in environments where smooth openings are required. The Vertical Lift Sectional Door offers excellent thermal isolation, enhanced security, and a wide range of design options to suit different industrial applications.

Main advantages of vertical lift sectional doors

Efficient space utilisation

The Vertical Lift Sectional Door is designed to avoid the occupation of lateral space by conventional door bodies by opening vertically. This is essential in environments where space utilization needs to be maximized, such as high-ceilinged workshops or small warehouses. Whether it’s above the shelves in a warehouse or in a work area on the production floor, the Vertical Lift Sectional Door maximizes space efficiency.

Superior sealing performance

These doors feature a high-quality sealing design that prevents the entry of dust, debris, or outside air, keeping the internal environment clean. This is particularly important in locations with high cleanliness requirements, such as food processing plants, chemical storage, and electronics manufacturing.

Adaptable

Vertical lift sectional doors are adaptable to different industrial needs and excel in harsh environments. For example, these doors operate smoothly in high wind speeds and temperature differences, making them ideal for use as a key part of a door control system. In windy areas, the sealing and structural strength of the vertical lift sectional doors are up to the challenge.

Security and anti-theft features

Vertical lift sectional doors feature robust metal materials and advanced locking systems to prevent unauthorized access. This makes them ideal for use in high-security environments. Combined with auto-sensing technology, the doors are able to stop automatically when an obstacle is detected, further enhancing security.

Technical features and innovations

Automation and Intelligent Control

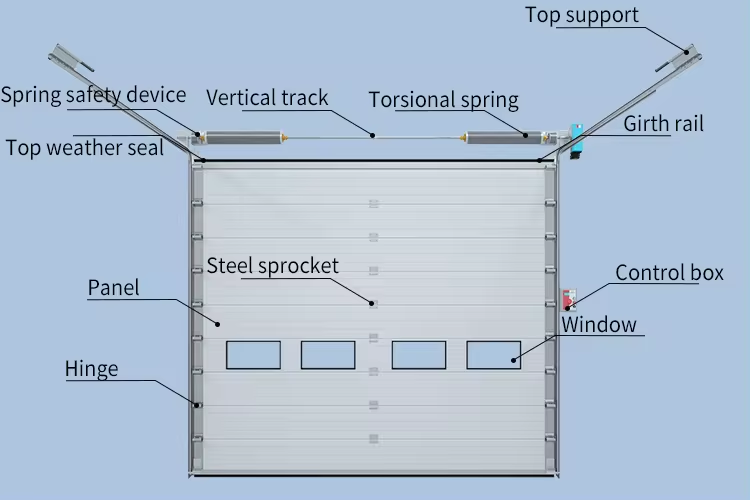

Modern vertical lift sectional doors are increasingly equipped with automation control systems, including intelligent sensing, remote control, and automatic locking. Intelligent control systems not only improve operational efficiency but also adjust the opening and closing speed of the door according to demand. For environments that require frequent opening and closing, these intelligent systems greatly improve operational convenience and safety.

High Strength Materials and Durability

These door bodies are typically made of high-strength steel, aluminum alloys, or composite materials. Which are able to maintain good performance in high-frequency operations. Compared with traditional wooden or thin steel doors, vertical lift sectional doors have higher impact and wear resistance and can withstand impact and friction in harsh environments.

Energy efficient design

As energy efficiency requirements increase, the design of sectional doors tends to be energy efficient and environmentally friendly. Most of the door bodies are insulated and sealed to help maintain the temperature balance between the inside and outside of the door. These designs not only help to reduce energy consumption but also help businesses reduce operating costs.

Advanced sealing and draught proofing

For windy areas or locations that require a high level of sealing, the draught-proofing features and sealing performance of vertical lift sectional doors are a great advantage. They prevent the entry of sand, dust, or humid air, ensuring a clean and stable environment in the workshop or warehouse.

Application Scenarios for Vertical Lift Sectional Doors

Warehouses and logistics centres

Vertical lift sectional doors are ideal for warehouses and logistics centers, especially when moving large quantities of goods. These doors open and close quickly, providing efficient sealing that allows goods to move in and out swiftly while maintaining the temperature and cleanliness inside the warehouse, unaffected by the external environment.

Manufacturing plants and production halls

In manufacturing plants, sectional overhead doors save space and increase the efficiency of the production area. They provide fast and safe access without taking up floor space, ensuring a smooth production process.

Food processing plants

For food processing plants, the insulation and sealing properties of sectional doors help to maintain constant temperature and humidity. While preventing the entry of contaminants and ensuring hygienic food safety.

Airports and high-traffic areas

In high-traffic areas such as airport terminals and cargo terminals. Industrial sectional doors provide fast access and a high level of durability and safety to ensure the efficient flow of people and goods.

How to choose the right vertical lift sectional door

Evaluate Functional Requirements

When choosing the right vertical lift sectional door, you first need to assess the actual needs of your business. Does it need to open and close quickly? Does it need to be insulated or fireproof? Based on these needs, choose the most appropriate type of door body.

Consider safety and maintenance costs

Safety is an important consideration when choosing a vertical lift sectional door. For locations with high-security requirements, choose a door body with security locks, automatic sensing, and anti-collision features. At the same time, choosing a door body with high durability and low maintenance costs can effectively reduce the cost of long-term use.

Choose products that comply with standards

When choosing, make sure the door body meets the relevant national or regional safety and quality standards. For example, fire door bodies and wind-resistant door bodies should comply with relevant building and fire standards.

Conclusion

I sectional doors have become an indispensable solution in modern industrial environments due to their efficient use of space, excellent safety, superior insulation, and energy-saving benefits. By choosing the right type of door, companies can effectively increase work efficiency, reduce energy consumption, ensure safety, and maximize the use of space in their facilities. Understanding the technical features and application scenarios of vertical lift sectional doors will help you make the most informed choice.

Frequently Asked Questions (FAQ)

What environments are Sectional Doors suitable for?

Vertical sectional doors are ideal for environments that require high space utilization and high traffic flow in and out. Such as warehouses, production plants, cold stores, logistics centers, etc.

What is the lifespan of a vertical sectional door?

Under normal use and regular maintenance, the lifespan of a vertical sectional door can usually reach 10-15 years.

How to maintain a vertical sectional door?

Regular cleaning of the tracks, inspection of the electric system, and lubrication of the moving parts are essential to ensure that the door operates properly for a long period. A thorough inspection is recommended at least once a year.