In modern industrial and commercial environments, door bodies are more than just openings in buildings; they play a vital role in enhancing productivity, ensuring security, and optimizing the use of space. As global logistics, production, and warehousing activities increase, so does the demand for door solutions. Traditional door designs often cannot meet the multiple demands of high-frequency opening and closing, high traffic flow, and space constraints, making Spiral Fast doors the preferred choice for more and more organizations.

Spiral Fast Doors are a highly efficient and energy-saving automated door solution, with a unique spiral lifting design that allows the door to open and close quickly in the vertical direction, maximizing the use of space. Compared to traditional rolling or sliding doors, Spiral Fast Doors offer significant advantages in terms of speed, space utilization, energy consumption, and security. Whether it is a logistics center, production workshop, warehouse, or cold chain logistics and food processing industry. Spiral Fast Door with its excellent performance and design, is becoming the industry standard.

This article will provide you with a comprehensive analysis of the working principle, advantages, and application scenarios. And how to choose the most suitable door body according to the actual demand. Through an in-depth understanding of the different types of spiral doors, you will be able to meet the safety. Improve work efficiency energy saving emission reduction, and other aspects of the needs of the basis, to make the most informed choice.

What is a Spiral Fast Door?

Spiral Fast Doors is a highly efficient automated door body characterized by its unique spiral design, which is widely used in industrial, commercial, logistics, and high-traffic environments. Unlike traditional rolling or sliding doors, Spiral Fast Doors are designed to lift vertically and open and close on a rotating basis. Allowing the door to open and close quickly while maximizing space utilization through a special spiral track system. Due to its compactness and fast opening and closing speeds, the Spiral Rapid Door has become the preferred door body solution for many high-frequency use environments.

This type of door body is suitable for a variety of places that require rapid access. Especially in environments with limited space, strict temperature control requirements, or high-security requirements. With its high efficiency, energy-saving, and safety features. The spiral speed door has gradually become an indispensable part of modern industrial and commercial environments.

Working Principle of Spiral Rapid Door

Principle of operation and design

The core feature of a spiral fast door is its spiral design. The panels of the door body rotate along the spiral track and quickly lift up and down, avoiding the problem of the traditional door body requiring horizontal space. This design not only saves space but also enables fast opening and closing operations. Reducing the friction and resistance of the door body operation, thus reducing energy consumption.

The door body is usually made of high-strength steel, aluminum alloy, or corrosion-resistant materials, which can withstand the challenges of frequent opening and closing and different environments. The control system of the spiral speed door is equipped with automatic sensing and intelligent control technology. Which can automatically adjust the opening and closing speed and time according to the needs of the environment.

Key components

Electric motor: responsible for driving the door body to raise and lower rapidly, ensuring that the door opens and closes in a short period.

Spiral track system: The door panel rotates along the track to ensure smooth and fast opening and closing.

Door curtains: usually made of strong, durable materials (such as aluminum alloy or stainless steel) that provide both fast opening and closing and a good seal.

Control systems: These include intelligent controllers, sensors, etc.. Which can adjust the speed and frequency of opening and closing of the door body according to the needs of the workshop or factory.

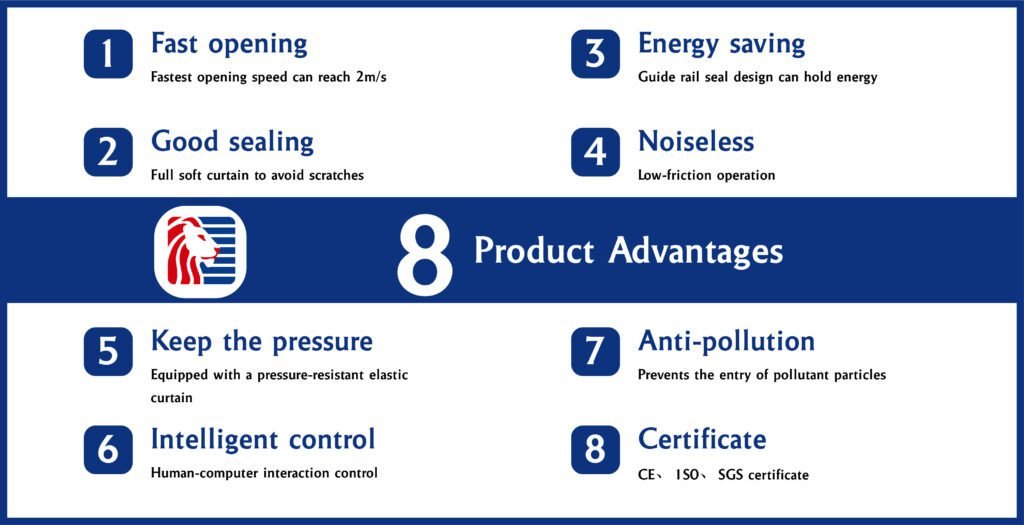

Advantages of spiral speed doors

High opening speed and efficiency

One of the biggest advantages of the spiral fast door is its ultra-fast opening and closing speed, usually within a few seconds to complete the opening or closing, suitable for high-flow, high-frequency access to the environment. Compared with traditional roller shutter doors or sliding doors. The opening and closing speed of the spiral speed door greatly improves the efficiency of work, especially in the logistics center, production workshop. And other places that require frequent access.

Space saving and flexibility

While traditional door designs usually require a large space for opening and closing. Spiral speed doors make clever use of vertical lifting design to reduce the need for horizontal space occupied by the door body, making it easy to install and use in places with limited space. For example, in limited-space environments such as production halls and warehouses, spiral speed doors can save valuable space for businesses.

Improved safety

The structural design of the spiral door provides increased safety. The door body is made of robust and durable materials that are impact-resistant and protect against external interference. In addition, many spiral doors are equipped with an advanced locking system and an auto-reverse function that automatically stops and reverses the door when it encounters an obstacle, avoiding damage to personnel and equipment.

Energy Saving and Environmentally Friendly

Spiral doors are made of highly efficient insulation materials and, due to their fast opening and closing speeds, can reduce heat or cold air loss when the door is opened. In cold storage warehouses, and pharmaceutical factories. And other environments with strict requirements for temperature control. Spiral fast doors can help companies reduce energy consumption and lower the burden on air conditioning and refrigeration systems.

Why use spiral speed doors?

Improve efficiency

The high-speed opening and closing of spiral-speed doors make them ideal for environments where efficient material flow is required. In logistics centers and production plants, rapid access doors can effectively increase efficiency and reduce waiting times for items to enter and exit. Its short opening and closing times are vital in most high-traffic locations, ensuring a constant flow of production lines or goods and improving overall productivity.

Save space and optimise layout

In many modern production facilities and warehousing environments, space resources are extremely valuable. Spiral speed doors are designed to save lateral space, avoiding the problem of traditional doors taking up too much space. For workshops, warehouses, or small plants with limited space, spiral speed doors can make more effective use of vertical space, allowing for a more optimized factory and warehouse layout.

Enhanced safety and protection

The spiral door provides an ideal solution for places where high security is required. The door body is made of high-strength materials, preventing external intrusion and reducing the risk of theft and vandalism. Especially in combination with an intelligent control system, spiral speed doors can further enhance security by limiting access to unauthorized persons.

Reducing energy consumption and maintaining a temperature-controlled environment

In cold chain logistics and temperature-controlled environments, changes in temperature may affect the quality of stored goods. Through its good sealing and faster opening and closing speeds, the spiral speed door can effectively avoid internal temperature loss and reduce the burden on air-conditioning and refrigeration systems, helping companies save energy and reduce running costs.

Why use spiral speed doors?

Improve efficiency

The high-speed opening and closing of spiral-speed doors make them ideal for environments where efficient material flow is required. In logistics centers and production plants, rapid access doors can effectively increase efficiency and reduce waiting times for items to enter and exit. Its short opening and closing times are vital in most high-traffic locations, ensuring a constant flow of production lines or goods and improving overall productivity.

Save space and optimise layout

In many modern production facilities and warehousing environments, space resources are extremely valuable. Spiral speed doors are designed to save lateral space, avoiding the problem of traditional doors taking up too much space. For workshops, warehouses, or small plants with limited space, spiral speed doors can make more effective use of vertical space, allowing for a more optimized factory and warehouse layout.

Enhanced safety and protection

The spiral door provides an ideal solution for places where high security is required. The door body is made of high-strength materials, preventing external intrusion and reducing the risk of theft and vandalism. Especially in combination with an intelligent control system, spiral speed doors can further enhance security by limiting access to unauthorized persons.

Reducing energy consumption and maintaining a temperature-controlled environment

In cold chain logistics and temperature-controlled environments, changes in temperature may affect the quality of stored goods. Through its good sealing and faster opening and closing speeds, the spiral speed door can effectively avoid internal temperature loss and reduce the burden on air-conditioning and refrigeration systems, helping companies save energy and reduce running costs.

Comparison of Spiral Rapid Door with other High Speed Doors

Comparison with Rolling Shutter Doors

Compared to a traditional roller shutter door, a spiral speed door opens and closes significantly faster while not taking up horizontal space. Rolling shutter doors need to be unfolded on the horizontal plane, taking up more floor space. Spiral speed doors make more efficient use of vertical space through the design of spiral tracks, suitable for places with strict space requirements.

Comparison with sliding doors

Die sliding door usually requires large lateral space, and the opening and closing speed is slow. The spiral fast door can complete the opening and closing operation in a very short time through its spiral track system. And is not subject to space limitations, which is suitable for frequent opening and closing environments.

Comparison with fast folding door

While fast folding doors offer some advantages in terms of quick opening and closing, they are usually not comparable to spiral doors in terms of durability, sealing, and impact resistance. Spiral speed doors are designed to offer greater durability and stability for long periods of intense use.

Application Scenarios of Spiral Rapid Door

Warehouses and logistics centers

Spiral speed doors are very suitable for Logistikzentren und Lagerhäuser, especially in areas where frequent opening and closing is required. Thanks to their high-speed opening and closing and space-saving features, spiral-speed doors can improve the efficiency of entry and exit, and reduce waiting time. And ensure the rapid flow of materials and products.

Production halls

In production halls, spiral speed doors can improve the efficiency of Produktionslinien. Thanks to their high-speed operation and durability, spiral-speed doors can cope with large-scale access requirements, ensuring that production lines are not blocked and improving overall productivity.

Kühlkettenlogistik

In the cold chain logistics industry, the spiral door can effectively prevent the inflow of outside air and maintain a stable internal temperature through its excellent sealing and insulation performance. Especially in cold storage warehouses, spiral speed doors can help companies reduce energy consumption and keep products fresh.

Pharmaceutical industry

Unter pharmaceutical factories and the medical industry, the sealing and hygienic properties of the spiral fast door make it an ideal choice. It prevents the entry of contaminants and ensures a clean production and storage environment.

How to choose the right spiral speed door

Evaluate the needs of use

When choosing a spiral fast door, you first need to assess the actual needs of the door. Environments that require high-frequency switching are suitable for selecting high-speed switching-type spiral doors. If the temperature control requirements are high, you should select spiral doors with better thermal insulation performance.

Consideration of environmental factors

Consider the special needs of the installation environment. Such as whether the door body needs to be windproof, dustproof, or anti-corrosion features. For environments with heavy moisture, spiral speed doors made of aluminum alloy or, stainless steel may be more suitable.

Budget and long-term costs

Although the initial investment in spiral doors is high, they are energy-saving, and durable. And low-maintenance features make them less costly in the long term. Therefore, the choice needs to be based on a combination of budget and long-term return on the door.

Technical features and innovations in spiral speed doors

Automatic Sensing and Intelligent Control

Modern spiral speed doors are equipped with auto-sensing technology. Which enables the door to open automatically when it senses people or objects approaching. Enterprises can control the opening and closing of the door body by remote control, wall switch, or integrated intelligent control system. The intelligent system not only provides convenient operation but also adjusts the opening and closing speed and frequency. And running time of the door body according to actual needs, ensuring efficient and safe operation.

High strength material and durability

The panels of spiral speed doors are usually made of high-strength PVC, composite materials, or metal materials. That can withstand frequent opening and closing operations and harsh environmental conditions. Even in high temperatures, humidity, or chemically corrosive environments, spiral speed doors can maintain good performance.

Installation and Maintenance of Spiral Rapid Door

Installation requirements

The installation of the spiral door needs to be completed by professionals to ensure that the door body is compatible with the building structure and that the installation of the track system meets the requirements. Special attention should be paid to the size of the door body. The configuration of the operating system, and the connection of the electrical system during installation.

Wartung

The daily maintenance of spiral fast doors is relatively simple, but in order to extend the service life. It is still necessary to regularly clean the door body, check the track system, lubricate the moving parts, and check the electric system. Keeping the door body clean and operating smoothly will help to minimize breakdowns and extend the life of the door.

Market Trends and Developments in Spiral Rapid Doors

Market Demand

With the diversification of industrial and commercial needs, the market demand for spiral fast doors is gradually increasing. Especially in the fields of warehousing, logistics, and production workshops. In the future, with the increasing demand for high-efficiency and energy-saving door bodies, the market of spiral fast doors has a bright future.

Technological innovation

Spiral door technology is constantly innovating. Such as the introduction of intelligent control systems, more efficient drive systems, and the use of environmentally friendly materials. With the continuous development of these technologies, spiral fast doors will be more efficient, environmentally friendly, and intelligent.

Häufig gestellte Fragen (FAQ)

What is the lifespan of a spiral speed door?

The lifespan of a spiral door is usually 10 years or more, depending on the frequency of use and environmental conditions.

What industries are spiral doors suitable for?

Spiral doors are suitable for industrial and commercial environments with high-frequency opening and closing. Such as warehouses, production plants, cold chain logistics, food processing plants, and so on.

How can I reduce the maintenance costs of my spiral door?

Regular inspection of the motorized system, cleaning of the tracks, and lubrication of moving parts. Regular maintenance of the system can significantly reduce long-term maintenance costs.